Polygonal ring piece shaping device and method

A shaping device and polygonal technology, which is applied in the field of ring forging processing, can solve the problems that cannot be repaired and polygonal rings cannot be processed, and achieve the effect of simple and practical tooling structure, fast and convenient adjustment and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

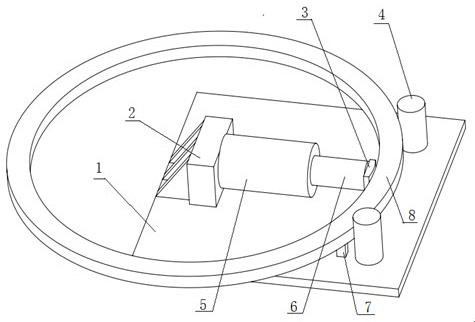

[0024] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0025] The invention discloses a polygonal ring shaping device, which comprises a ring blank 8 and an oil pressure system. The end of 6 is provided with a plug 3, the ring blank 8 is arranged between the plug 3 and the positioning column 4, and the oil cylinder 5 is connected with the hydraulic system.

[0026] The plug 3 is in the shape of an outer arc, and the plug 3 is fixedly connected to the end of the oil cap 6 .

[0027] The oil cylinder 5 is fixedly connected with the base 1 through the fixing seat 2 .

[0028] Two positioning posts 4 are arranged, and the two positioning posts 4 are arranged symmetrically around the center line of the top of the oil 6 , and the positioning posts 4 are fixedly connected with the base 1 .

[0029] A set of parallel irons 7 is arranged between the base 1 and the ring blank 8 .

[0030] One group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com