Rapid forging hydraulic press

A hydraulic press, a fast technology, applied in the field of forging hydraulic presses to achieve the effect of improving work efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

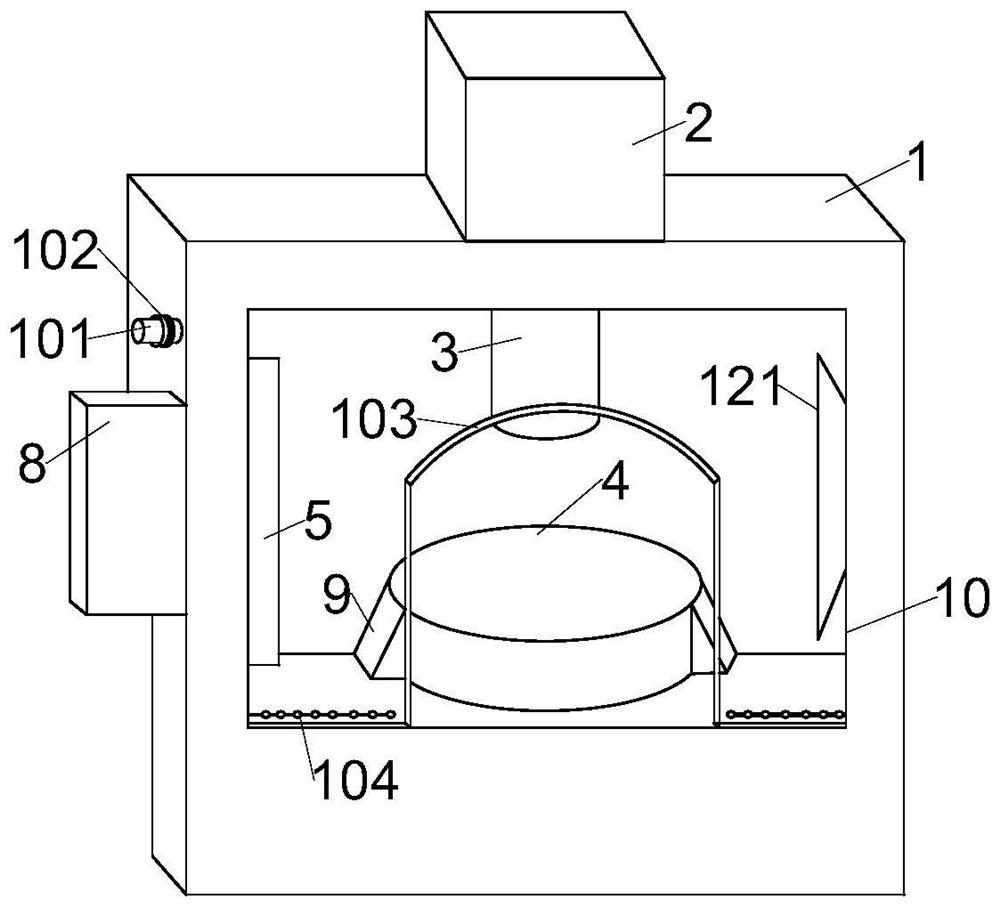

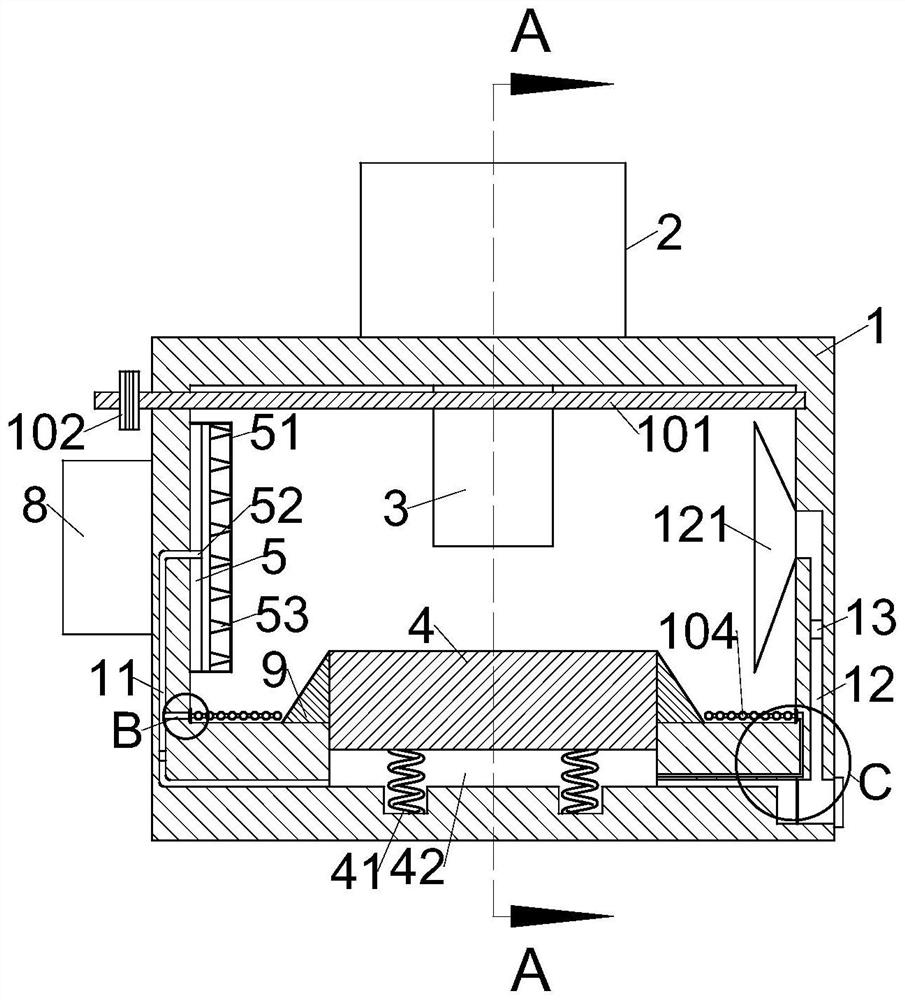

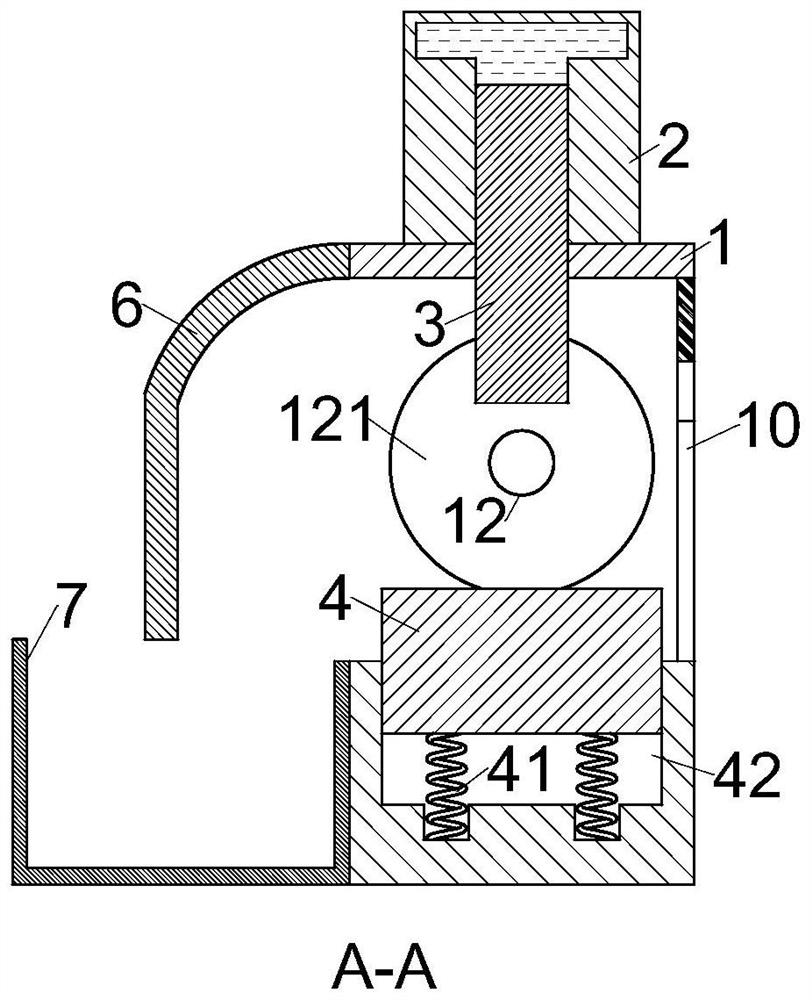

[0027] As a specific embodiment of the present invention, the housing 1 is fixed to the outer surface of the side of the cleaning device 5 secure the motor 8.

[0028] When a small fast forged hydraulic press is forged for metal, the metal will take off the oxidation skin. Since the hydraulic machine is rapidly forged to metal, the oxidized skin sometimes splashes around, thus generating damage to the staff, and the present invention controls the installation frame in the cleaning device 5 The rotation of 51 thus changing the angle of the jet 53 jet, which allows the nozzle 53 not only to clean the oxide skin on the force holder 4, but also cleans the oxidation of the surrounding spots, thereby reaching the oxidation on the force base 4. While clearance, the skin is also protected by the staff.

[0029] As a specific embodiment of the present invention, the upper surface of the housing 1 is fixedly connected to the fixed block 9, and the fixing block 9 is located on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com