Checking and aligning device used during mold closing of flaskless molding

A technology of boxless modeling and detection frame, which is applied in the direction of safety devices, manufacturing tools, casting equipment, etc., can solve the problems that cannot be inspected, and achieve the effect of solving the problem of photosensitive dead angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

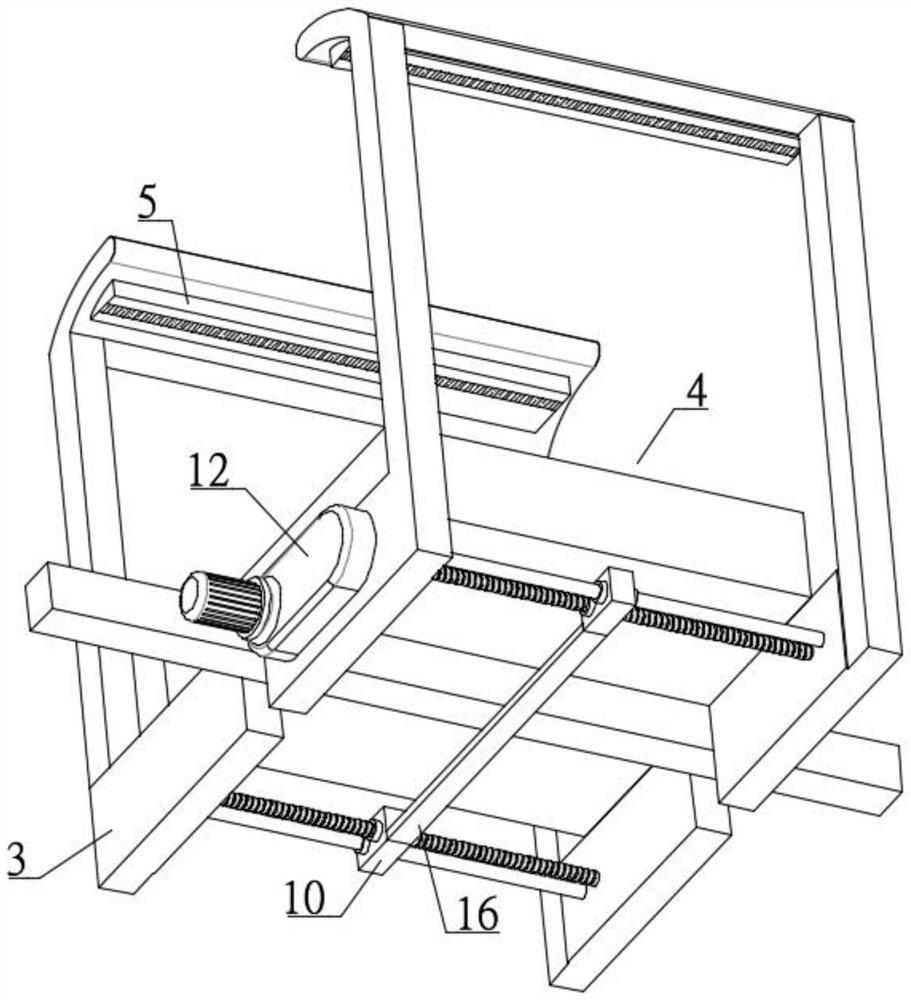

[0055] In this embodiment, the number of detection components is two, and the two detection components are symmetrically arranged on both sides of the electric slide rail 1 for synchronous detection, and the two laser emitter mounts 10 are fixed by a connecting frame 16, thereby Realize that two detection components share one power component 12 .

[0056]Wherein the ball screw 7 and the ball nut 6 in the detection assembly not directly connected with the power assembly 12 are replaced with light rods 8 and linear bearings 9, since only the ball screw 7 connected with the power assembly 12 is interesting, so the other The ball screw 7 and the ball nut 6 on one side are replaced, and the two light rods are slidably connected to the laser emitter mount 10, thereby reducing the movement resistance of the laser emitter mount 10 on the other side and improving stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com