Corrugated board forming and pressing auxiliary device

A corrugated cardboard and auxiliary device technology, which is applied in the direction of machining/deformation, can solve the problems affecting the overlapping degree, separation, and stacking of corrugated cardboard, and achieve the effect of reducing the amplitude of bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

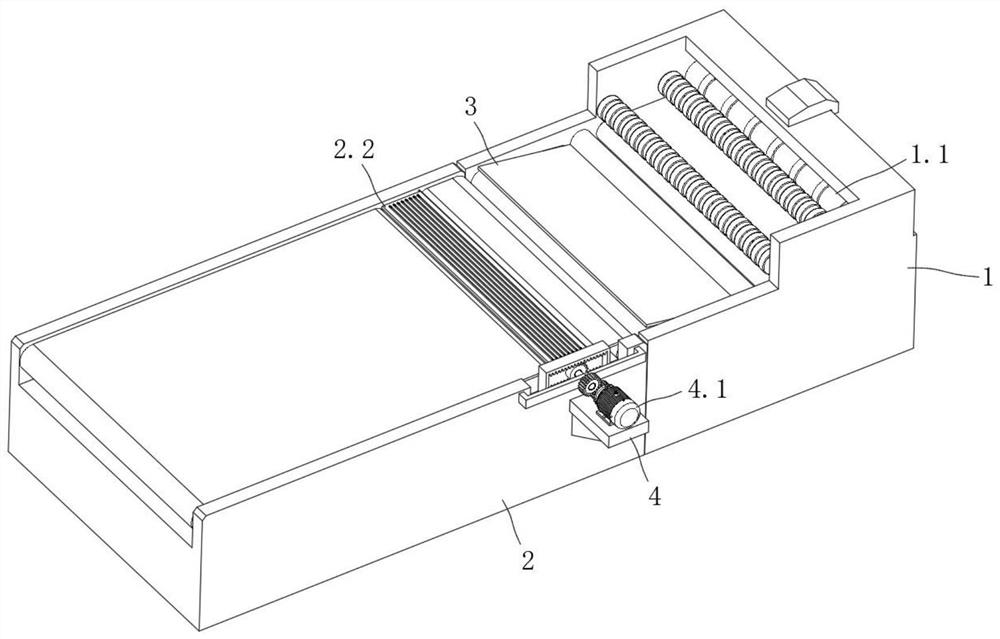

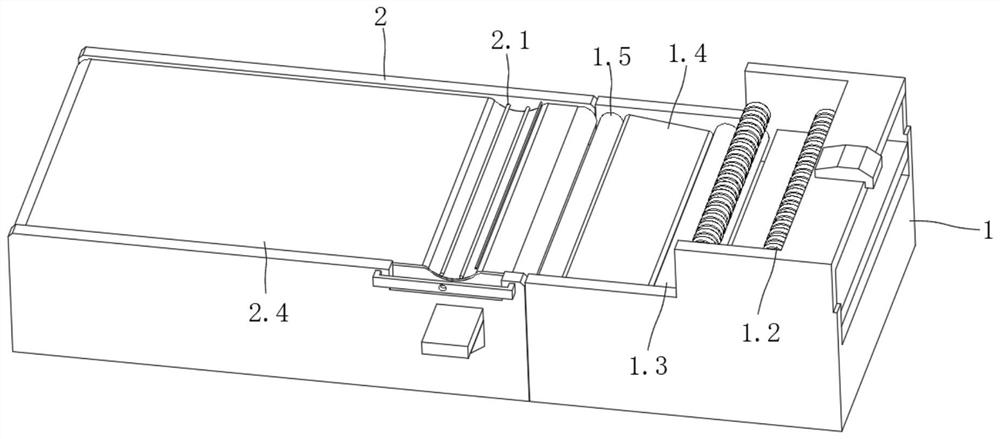

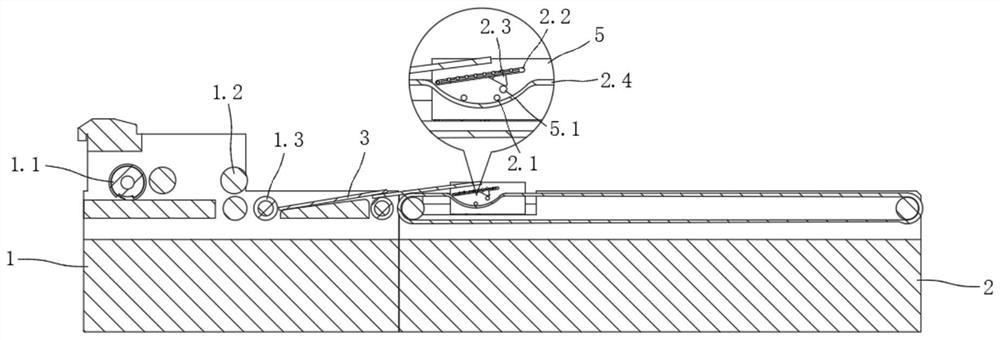

[0032] see Figure 1-11 , corrugated cardboard forming and pressing auxiliary device, used to solve the problem that the two overlapping corrugated cardboards in the inclined road section will be immediately conveyed to the conveyor belt in a horizontal state. When transported from an inclined state to the conveyor belt, there will be a forward and downward arc movement trend under the action of inertia. Under this movement, two corrugated cardboards will fall on the conveyor belt and cause certain bumps, which will affect the two corrugated boards. The overlapping degree of corrugated cardboard even makes the two separate, which affects the problem of subsequent stacking.

[0033] As the technical solution further proposed by the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com