Pre-processing equipment for peanut oil preparation

A pre-processing and peanut oil technology, which is applied in the field of pre-processing equipment for peanut oil preparation, can solve problems such as empty travel, inability to ensure continuous peanut shelling output, peanut accumulation and blockage, etc., achieve high work efficiency, and realize automatic shelling and screening The effect of dividing the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

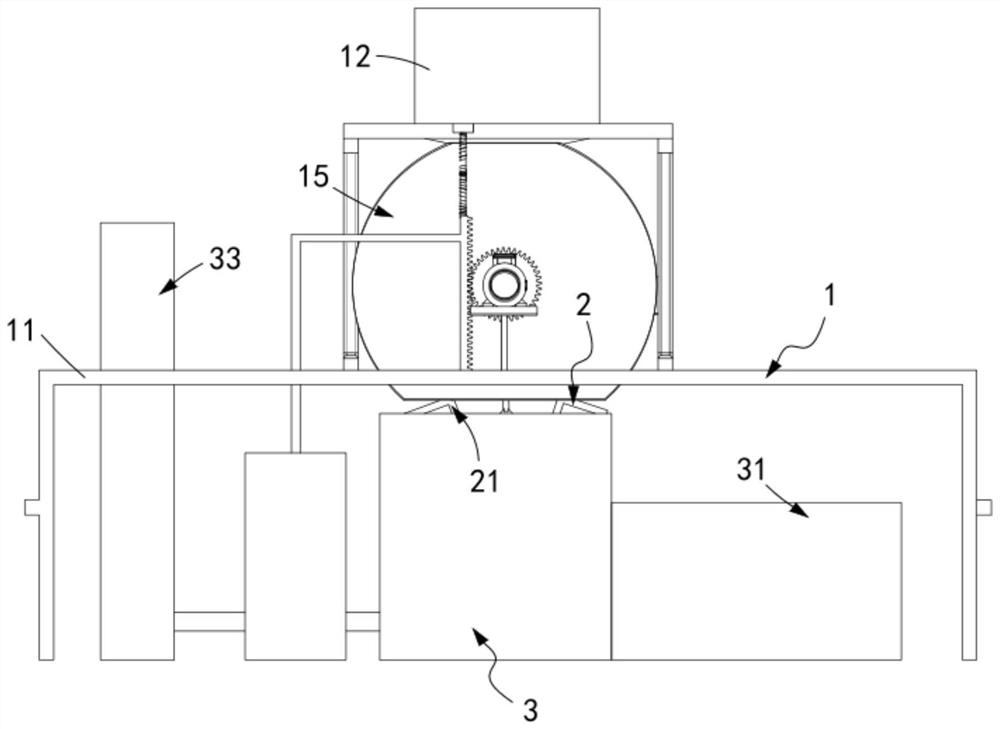

[0055] like figure 1 , figure 2 and Image 6 As shown, a pre-processing equipment for preparing peanut oil, comprising:

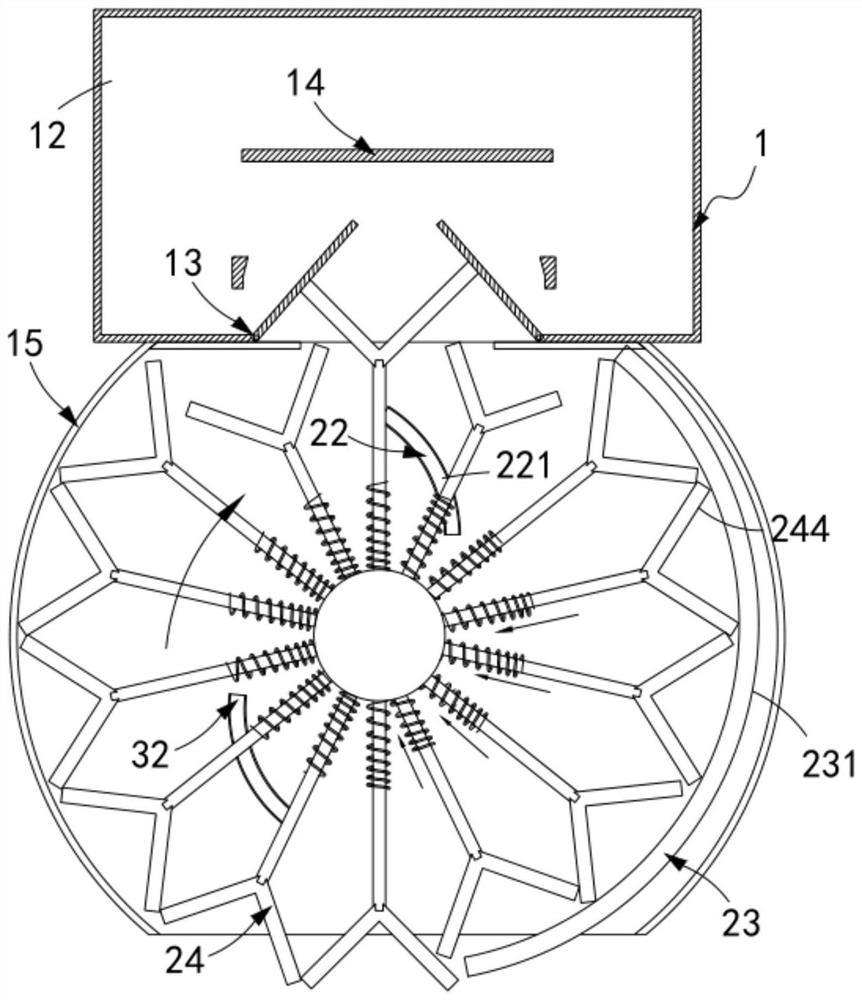

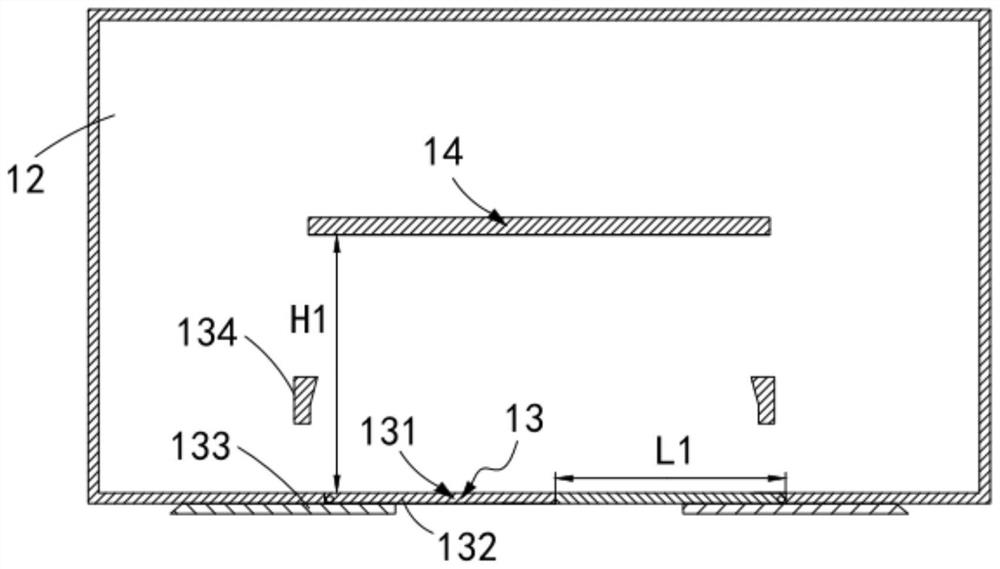

[0056] A feeding mechanism 1, the feeding mechanism 1 includes a discharging bucket 12 arranged on the frame 11, a control assembly 13 arranged at the output end of the discharging bucket 12 and used to control the automatic discharging of the discharging bucket 12, The pre-pressing plate 14 arranged in the discharging barrel 12 and provided with elastic material and the driving assembly 15 arranged under the discharging barrel 12;

[0057] The dehulling mechanism 2 includes a transmission assembly 21 driven by the drive assembly 15 to rotate in a circle, a first guide assembly 22 disposed in the drive assembly 15 and a first guide assembly 22 installed on the drive assembly 15 And the pressing component 23 that cooperates with the transmission component 21 to crush the peanuts 10. The transmission component 21 includes several groups of clamping compon...

Embodiment 2

[0094] like figure 2 , Figure 12 to Figure 13 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is:

[0095] further, as figure 2 , Figure 12 to Figure 13 As shown, the screening assembly 31 includes a water tank 311 for an open structure and a collection tank 312 located on one side of the water tank 311 .

[0096] It should be noted that the fruit shells 20 in the water tank 311 pulled out by the branch frame 244 automatically fall into the collection box 312 along the guide of the branch frame 244 under the action of gravity to perform the collection work.

[0097] In this embodiment, the clamping assembly 24 is separated from the arc-shaped plate 231 and then enters the water tank 311 , the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com