Large-torque blade type hydraulic motor

A hydraulic motor and vane-type technology, which is applied in the field of hydraulic motors, can solve the problems of small torque of vane-type hydraulic motors, and achieve the effects of reduced pump capacity, small frictional resistance, and high starting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

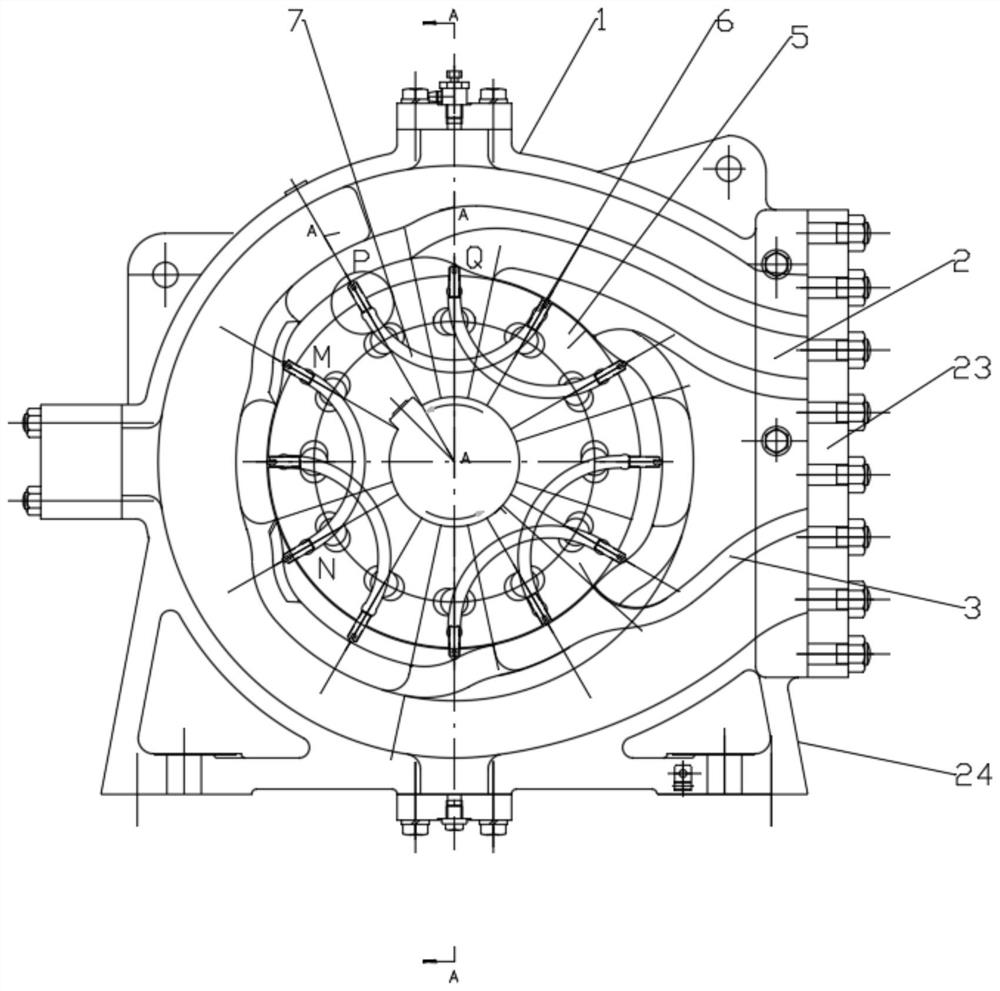

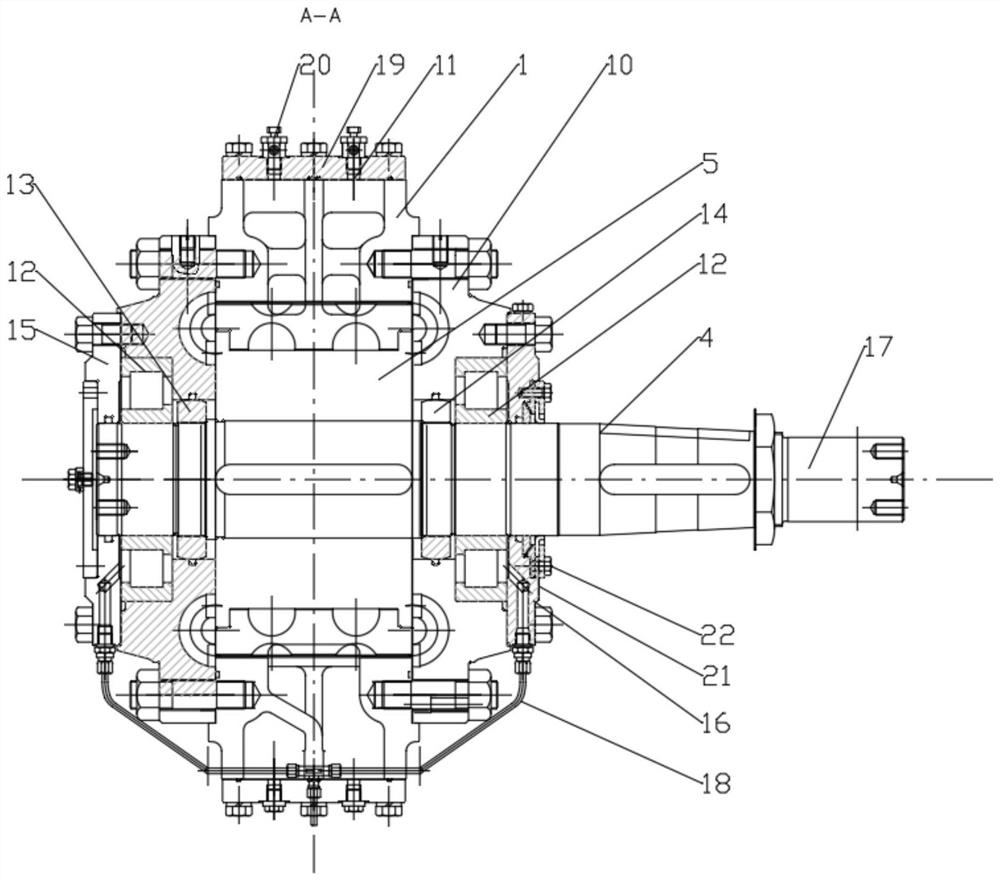

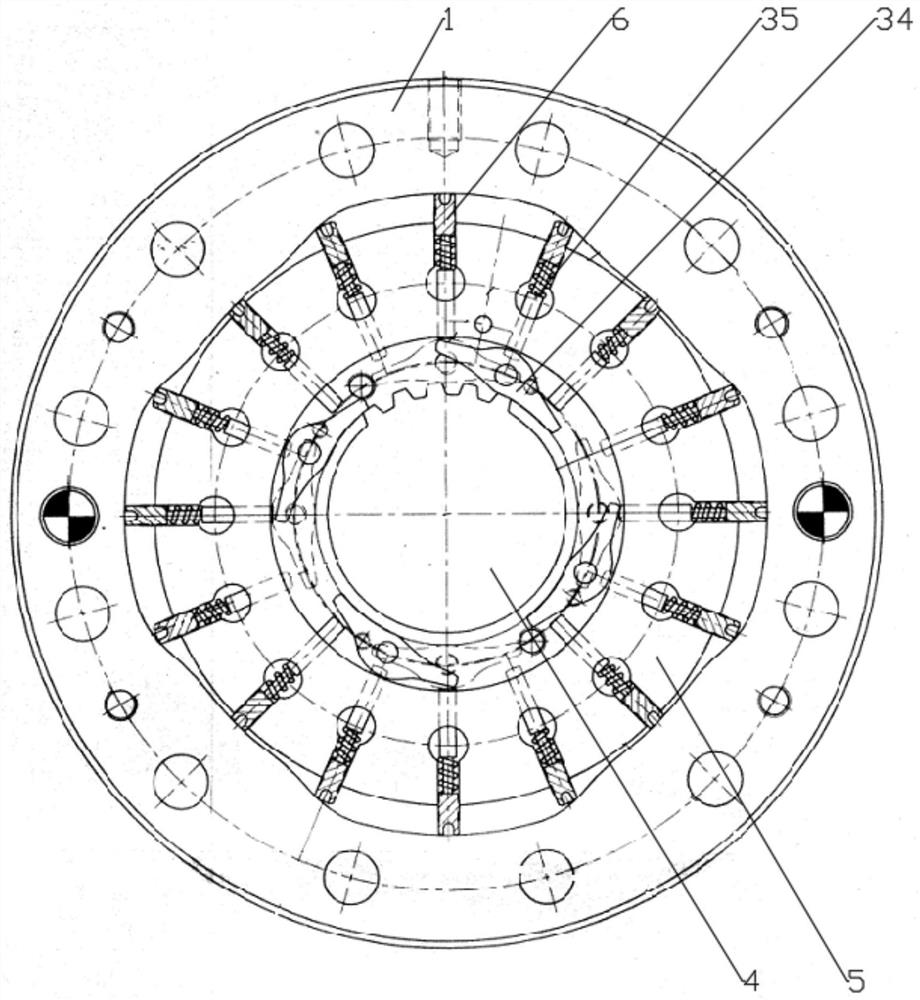

[0036] Such as figure 1As shown, a high-torque vane hydraulic motor includes a motor housing 1. The inner wall of the motor housing 1 forms a motor inner cavity 36 with a protruding petal-shaped structure in cross section. The oil inlet 2 and the oil outlet 3, the motor inner cavity 36 has a motor shaft 4, the motor shaft 4 is generally arranged along the central axis of the motor inner cavity 36 and the two ends of the motor housing 1 are rotatably worn, the motor shaft 4. The part located in the inner cavity 36 of the motor is fixedly provided with a rotor 5. The rotor 5 is cylindrical and ha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap