Adjustable multi-outlet synchronous valve

A synchronous valve, multi-exit technology, applied in the direction of fluid pressure actuation device, servo motor assembly, mechanical equipment, etc., can solve the problems of difficult processing, low synchronization accuracy, low efficiency ratio, etc., to simplify the processing technology and processing difficulty. , The effect of eliminating geometric dimension processing errors and improving synchronization accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

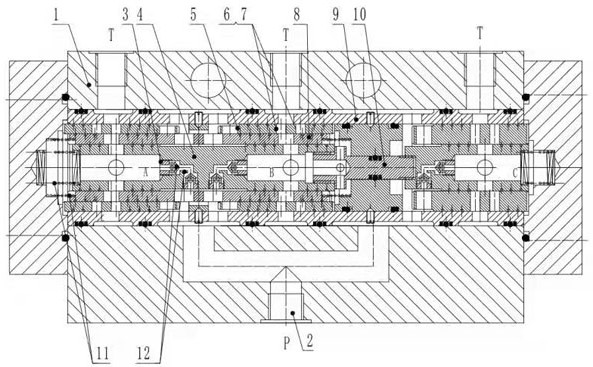

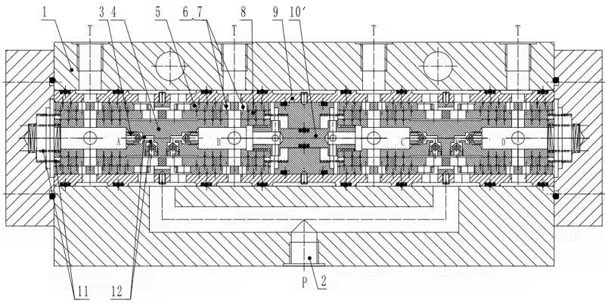

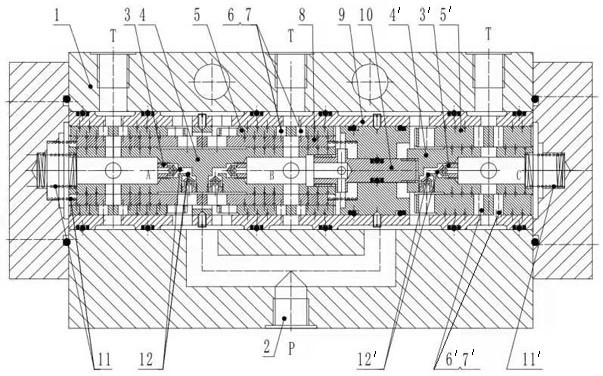

[0020] Depend on Figure 1-Figure 3 An adjustable multi-outlet synchronous valve according to the present invention is based on an adjustable synchronous valve with one inlet and two outlets as the basic unit. , the semi-through hole poppet valve 3 arranged symmetrically in the channel of the valve core 4 and its corresponding two cavities A cavity and B cavity, and the pressure compensating sliding sleeve 8 sequentially socketed outside the valve core 4, the reversing Sliding sleeve 5 and installation sleeve 9 are formed. The spool 4 is a cylindrical body with a recess in the middle, and the reversing sliding sleeve 5, the pressure compensation sliding sleeve 8 and the installation sleeve 9 are all hollow cylindrical structures and have corresponding hole groups, wherein the spool 4, The reversing sliding sleeve 5 and the pressure compensating sliding sleeve 8 can slide relative to each other.

[0021] The present invention is divided into two different structural forms: mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com