Mechanical quantitative adjustment torque limiter

A torque limiter and quantitative adjustment technology, which is applied to mechanical equipment, clutches, automatic clutches, etc., can solve problems such as complicated debugging process and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

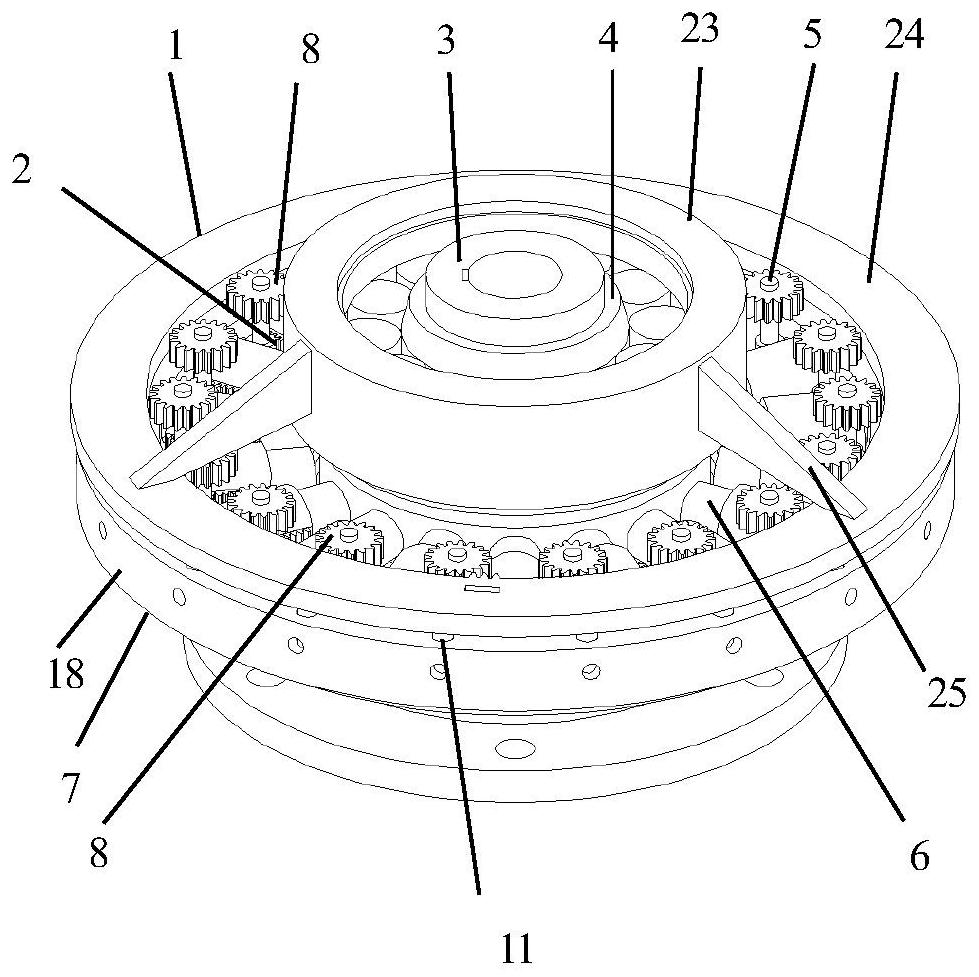

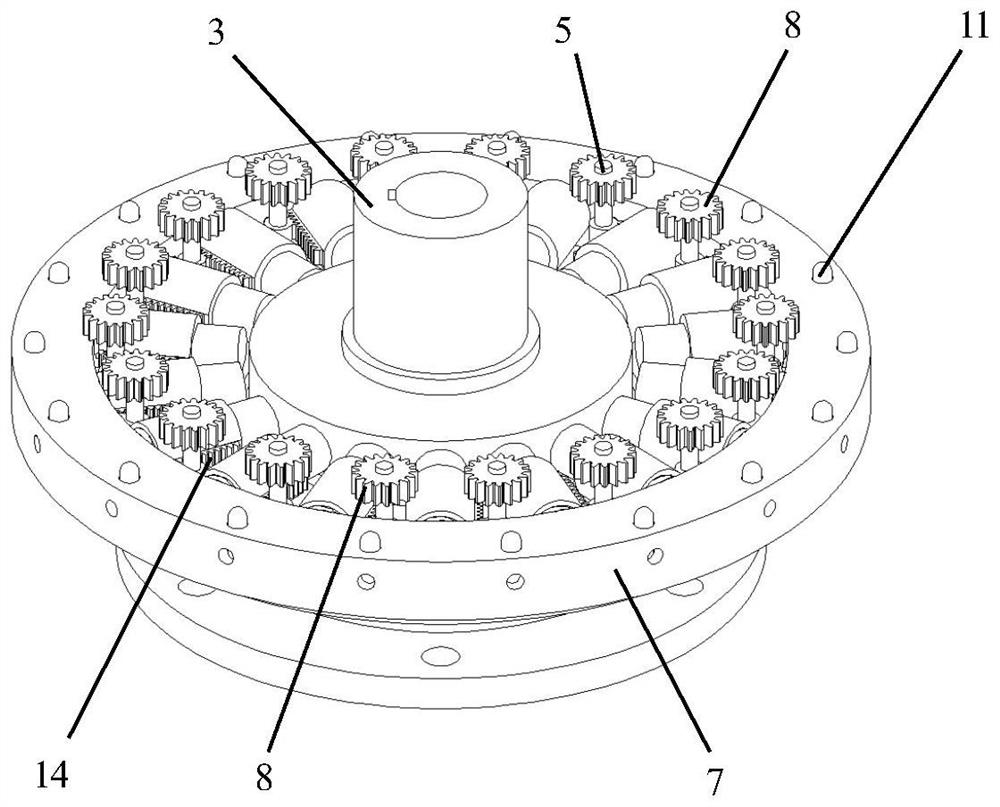

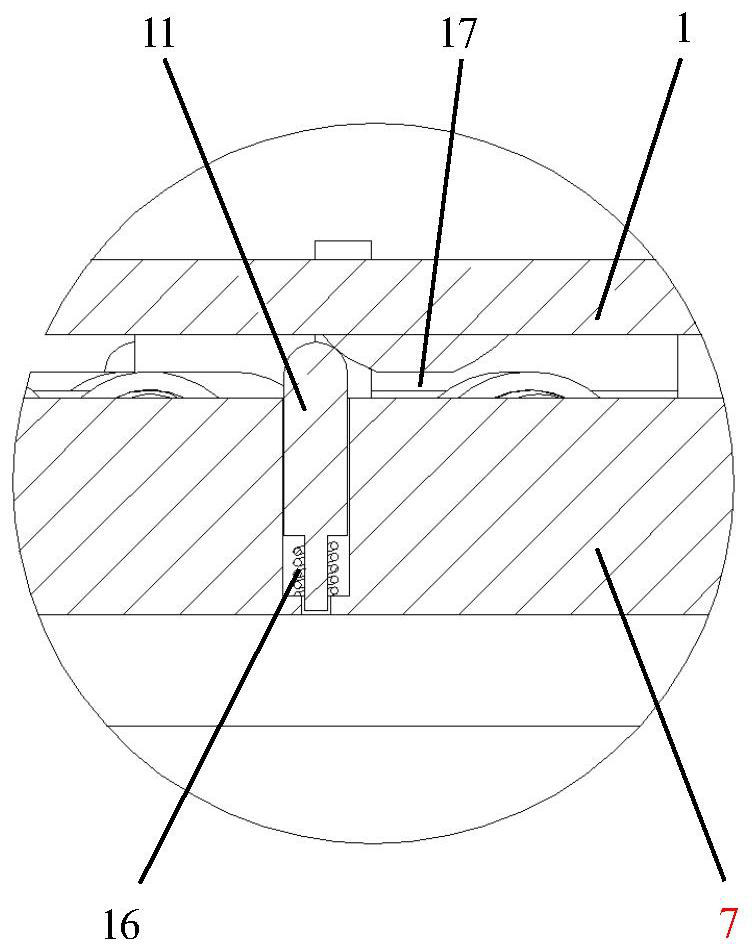

[0035] A mechanical quantitative adjustment torque limiter of this embodiment, such as figure 1 - 8, the composition includes:

[0036] Torque setting dial 1, incomplete gear for limit 2, output shaft 3, rolling bearing at output end 4, rotating shaft 5, a set of friction columns 6, input end flange 7, a set of toggle gear 8, a set of limit Pin 9, a set of limit compression springs 10, a set of guide pins 11, a scale window 12, a set of friction compression column springs 13, a set of limit racks 14, input end rolling bearings 15, a set of guide pin compression springs 16, One set of guide blocks 17;

[0037] A set of friction columns 6, a set of toggle gears 8, a set of limit pins 9, a set of limit compression springs 10, a set of guide pins 11, a set of friction compression column springs 13, a set of limit racks 14, The quantity of one group of guide pin compression springs 16, one group of guide pressing blocks 17 is suitable;

[0038] The following narrative methods an...

specific Embodiment approach 2

[0048] The difference from Embodiment 1 is that a mechanical quantitative adjustment torque limiter of this embodiment, such as figure 1 As shown in - 8, the friction compression column spring 13 is installed in the hole inside the friction column 6, and the friction column 6 has a detent inside to limit the stroke of the friction compression column spring 13.

specific Embodiment approach 3

[0049] Different from the specific embodiment one or two, the mechanical quantitative adjustment torque limiter of this embodiment, such as figure 1 - As shown in 8, the torque setting dial 1 includes an upper outer cover body 23, a lower ring body 24 and a set of waist pieces 25, and the upper outer cover body 23 and the lower ring body 24 are connected through the waist piece 25;

[0050] The torque setting dial 1 is set on the outside of the rolling bearing 4 at the output end through the outer cover body 23;

[0051] The gear tooth structure 22 is arranged on the inner wall of the ring body 24 of the torque setting dial 1;

[0052] A gear tooth structure 22 is provided for meshing with the toggle gear 8;

[0053] The set of guide blocks 17 is arranged on the lower surface of the ring body 24 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com