Parallel disassembly line setting method without merging priority relation matrixes

A priority relational matrix and linear programming technology, applied in the direction of complex mathematical operations, instruments, data processing applications, etc., can solve large-scale problems such as unsatisfactory solution quality, and achieve the effect of a good selection range and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

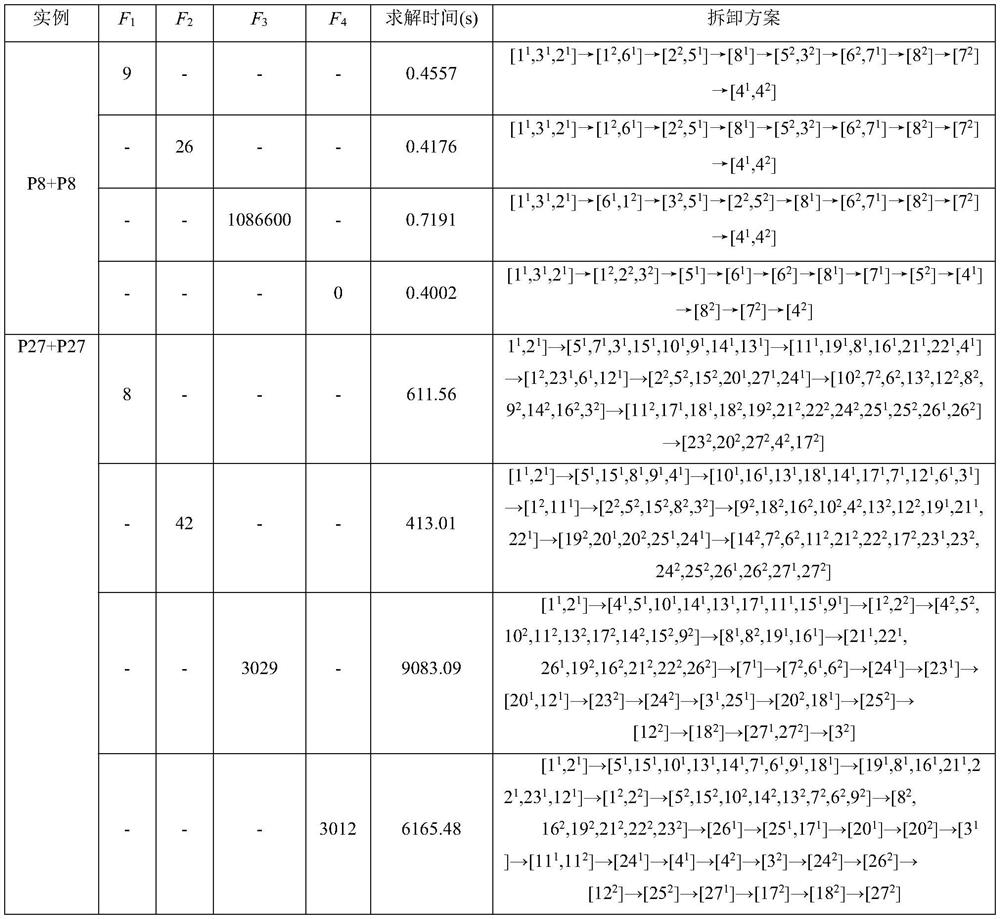

[0056] In order to highlight that this embodiment has a good effect on the small-scale parallel disassembly line balance problem and the large-scale parallel disassembly line balance problem, the following simulation experiments have been carried out:

[0057] Based on the data in the document "Atabu search algorithm for balancing a sequence-dependent disassembly line", the parallel disassembly simulation results of similar end-of-life products of P8+P8 are given; Based on the data, the parallel disassembly simulation results of similar end-of-life products of P27+P27 are given. The final simulation results are shown in Table 1.

[0058] Each component in the object to be disassembled, including hazard attributes, demand attributes, and priority disassembly relations, etc., are all derived from the above literature. In Table 1, the superscript indicates the serial number of the disassembly line, that is, the superscript 1 indicates the first disassembly line, and the superscri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com