Intelligent installation device for live-line work special-shaped parallel groove clamp

A technology for live work and installation of devices, applied in circuits, electrical components, conductive connections, etc., can solve problems such as large safety hazards, high risk factors, inconvenient operation, etc., to prevent safety accidents, high safety factor, and fast fixing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

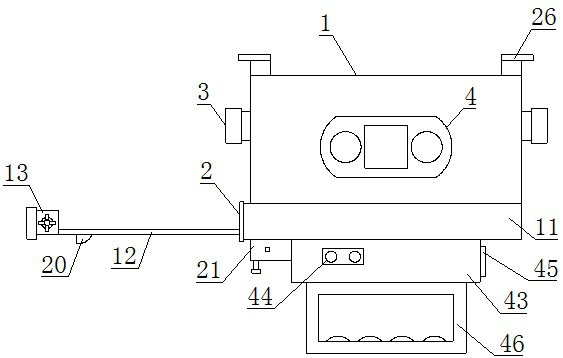

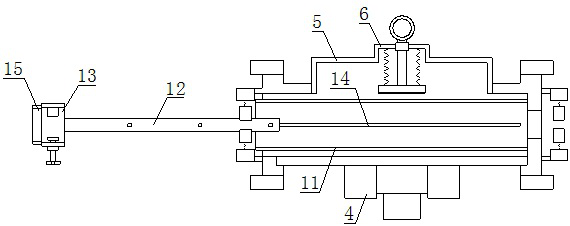

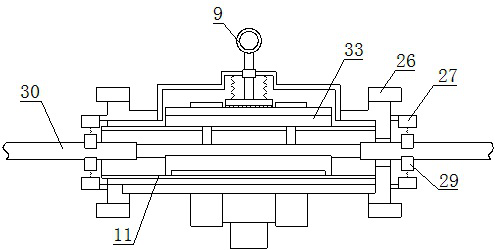

[0030] Such as Figure 1-12 As shown, the intelligent installation device for special-shaped parallel groove clamps for live work includes a clamp body 1, a slave line clamping mechanism 2, a main line clamping mechanism 3 and a bolt fastening mechanism 4, and the rear side of the clamp body 1 is provided with a place Groove 5, the middle part of the placement groove 5 is provided with a clamping frame 6, the inside of the clamping frame 6 is provided with a top shaft 7, and the front and rear ends of the top shaft 7 are respectively provided with a push plate 8 and a pull ring 9 , the rear side of the push plate 8 is provided with a spring A10, and the lower side of the clamp body 1 is provided with a slave wire clamping mechanism 2, and the slave wire clamping mechanism 2 includes a sliding cylinder 11, a suction tube 12 and a clamp Line block 13, the sliding groove 14 is provided on the lower side of the sliding cylinder 11, the suction pipe 12 is arranged inside the slidin...

Embodiment 2

[0038] Such as Figure 1-12 As shown, the intelligent installation device for special-shaped parallel groove clamps for live work includes a clamp body 1, a slave line clamping mechanism 2, a main line clamping mechanism 3 and a bolt fastening mechanism 4, and the rear side of the clamp body 1 is provided with a place Groove 5, the middle part of the placement groove 5 is provided with a clamping frame 6, the inside of the clamping frame 6 is provided with a top shaft 7, and the front and rear ends of the top shaft 7 are respectively provided with a push plate 8 and a pull ring 9 , the rear side of the push plate 8 is provided with a spring A10, and the lower side of the clamp body 1 is provided with a slave wire clamping mechanism 2, and the slave wire clamping mechanism 2 includes a sliding cylinder 11, a suction tube 12 and a clamp Line block 13, the sliding groove 14 is provided on the lower side of the sliding cylinder 11, the suction pipe 12 is arranged inside the slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com