Brush comprising tufts of bristles fixed by means of staples and wire for producing such staples

A technology of bristle tufts and brushes, which is applied in the direction of bristles, brushes, applications, etc., and can solve problems such as high material consumption, increased manufacturing cost, and high input force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

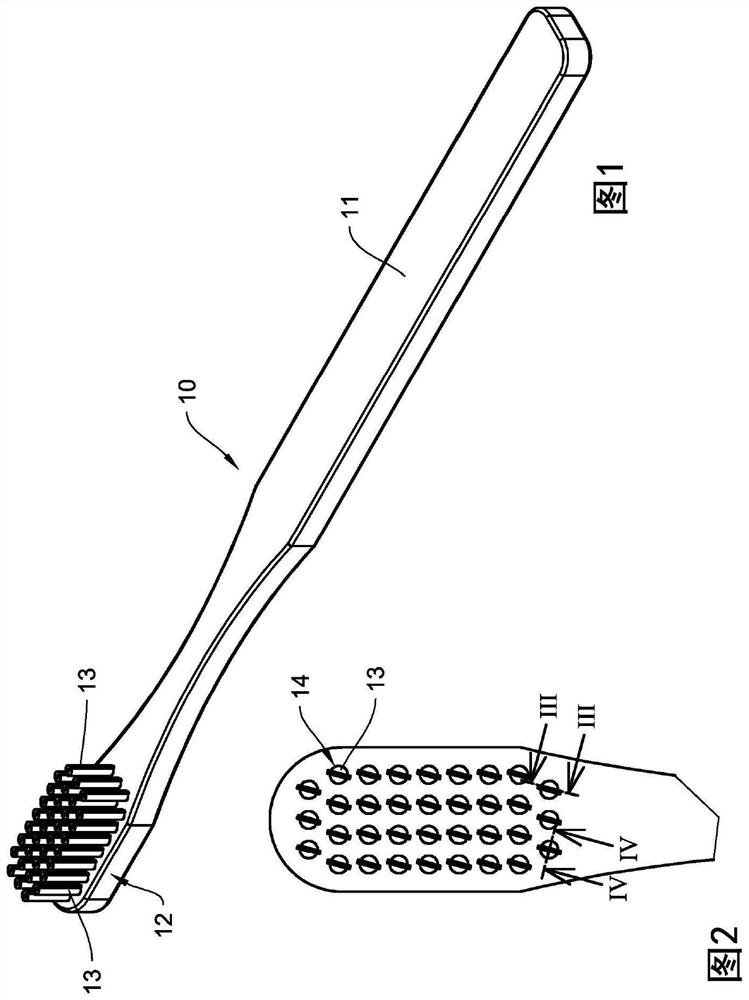

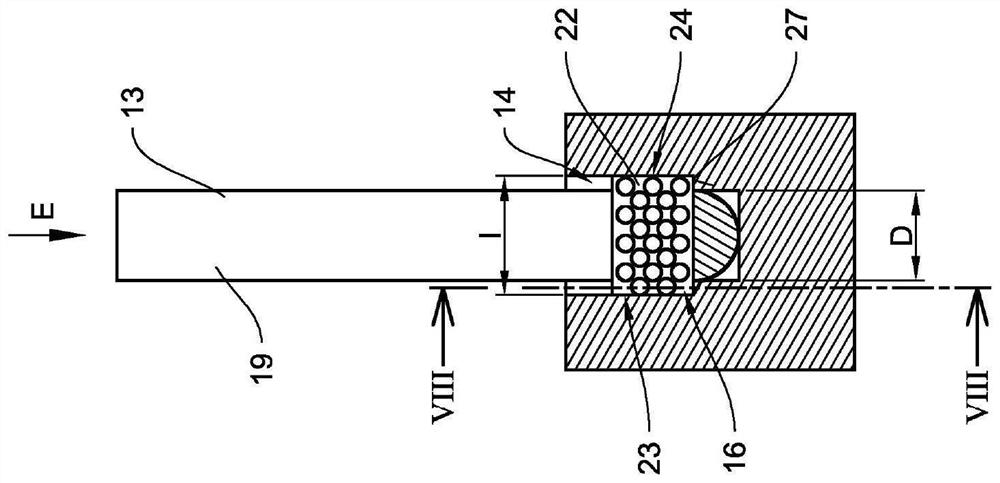

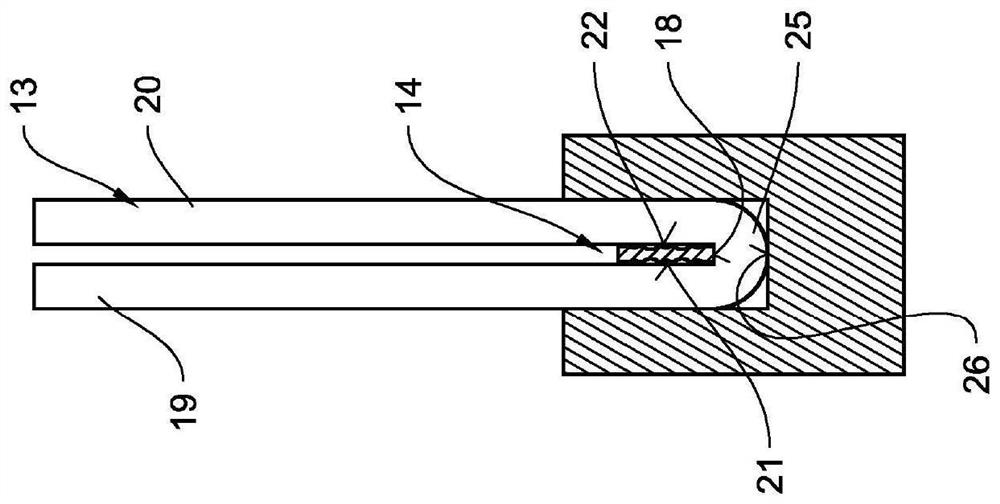

[0043]figure 1 Shown is a toothbrush 10 with a holder having a brush head as a holder 12 for a plurality of bristle tufts 13 at the end of the toothbrush body opposite the handle 11 . At least the brush head designed as support 12 is made of a plastically deformable plastic material and as in particular in figure 2 Shown in, the number of its tuft holes 14 corresponds to the number of bristle tufts 12, as in particular image 3 and Figure 4 As shown, bristle tufts 13 each consisting of a plurality of substantially parallel-oriented bristles or bristles are inserted and fixed in the tuft holes.

[0044] Depend on Figure 9 The staples 16 formed by the isometric cut sections of the wire 15 shown in are used to fix the bristle tufts 13 in the tuft holes 14, wherein as Figure 9 The staple is detached from the wire 15 as indicated by the detachment line 17 shown in .

[0045] If according to image 3 and Figure 4 An overview of the bristle tufts 13 can be understood to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com