Electrically-controlled embedded liftable mowing platform

A built-in, header technology, used in headers, cutters, harvesters, etc., can solve the problems of manual adjustment of mowing height, troublesome belt replacement for mowing platform, and reduction of header width. , to avoid overall maintenance and replacement, convenient and quick adjustment, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

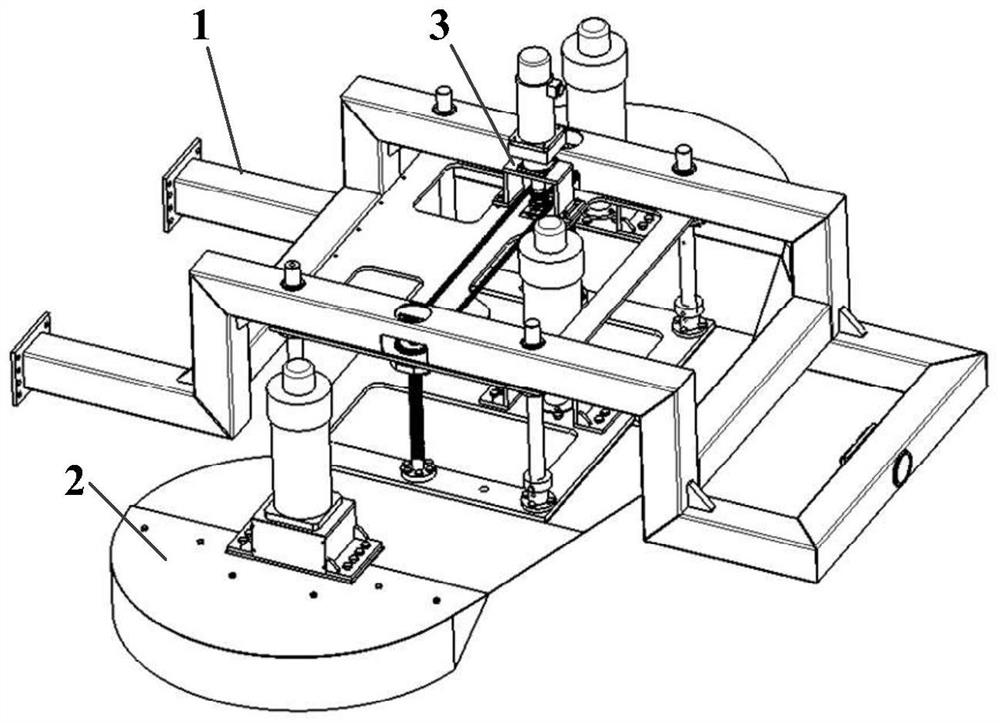

[0029] see Figure 1~5 An electric control built-in liftable mowing platform, including a vehicle frame 1, a header body 2 and a header lifting mechanism 3, wherein, the middle part of the frame 1 is provided with a mower for embedding the header body 2 Groove, described header elevating mechanism 3 is connected with header body 2, and concrete structure is as follows:

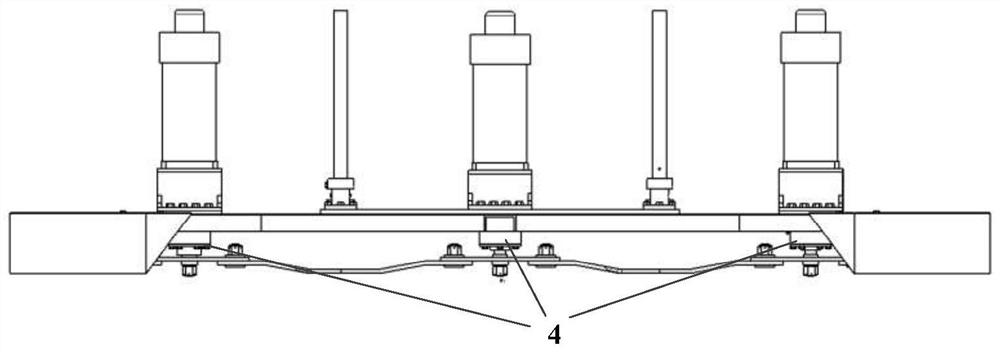

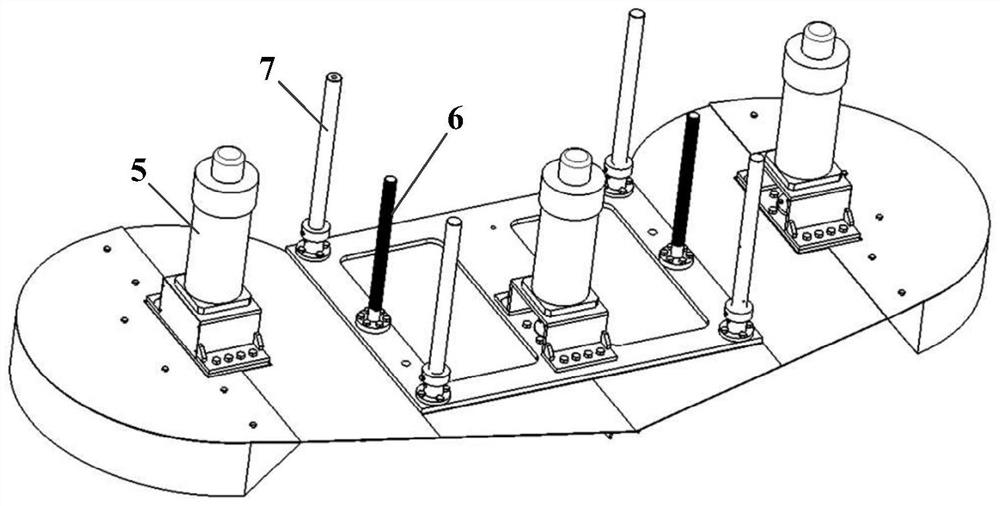

[0030] The header body 2 includes a cutter rotation mechanism 4, a mowing motor 5, a lifting screw 6, a lifting guide rod 7 and a header frame, and the header frame is composed of a left frame, a mounting frame and a right frame. And mowing motor 5 is respectively installed on the left bone platform, mounting frame and right bone platform, and mowing motor 5 is V-shaped arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com