Water permeable brick green brick raw material mixing and stirring equipment

A technology of mixing and stirring and permeable bricks, which is applied in the direction of mixers, mixer accessories, mixers with rotating mixing devices, etc., can solve the problems of low work efficiency, achieve the effect of improving accuracy and accurately controlling the amount of feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

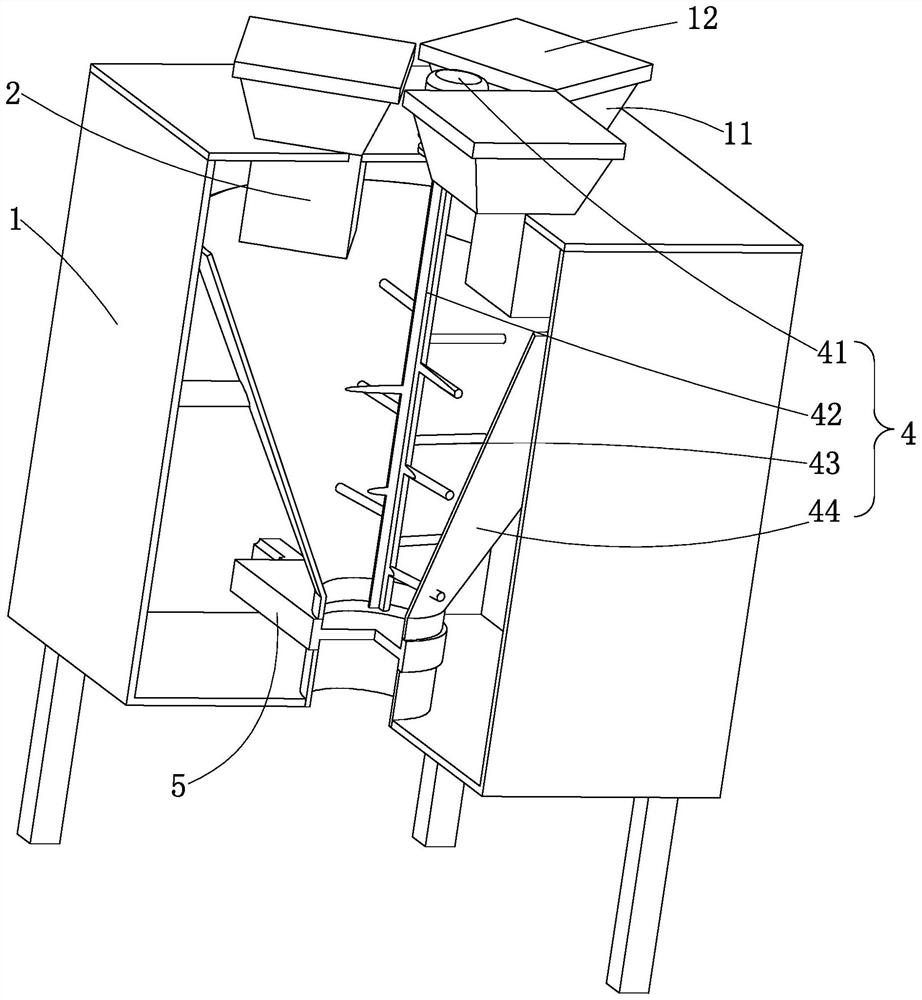

[0033] The following is attached Figure 1-6 The application is described in further detail.

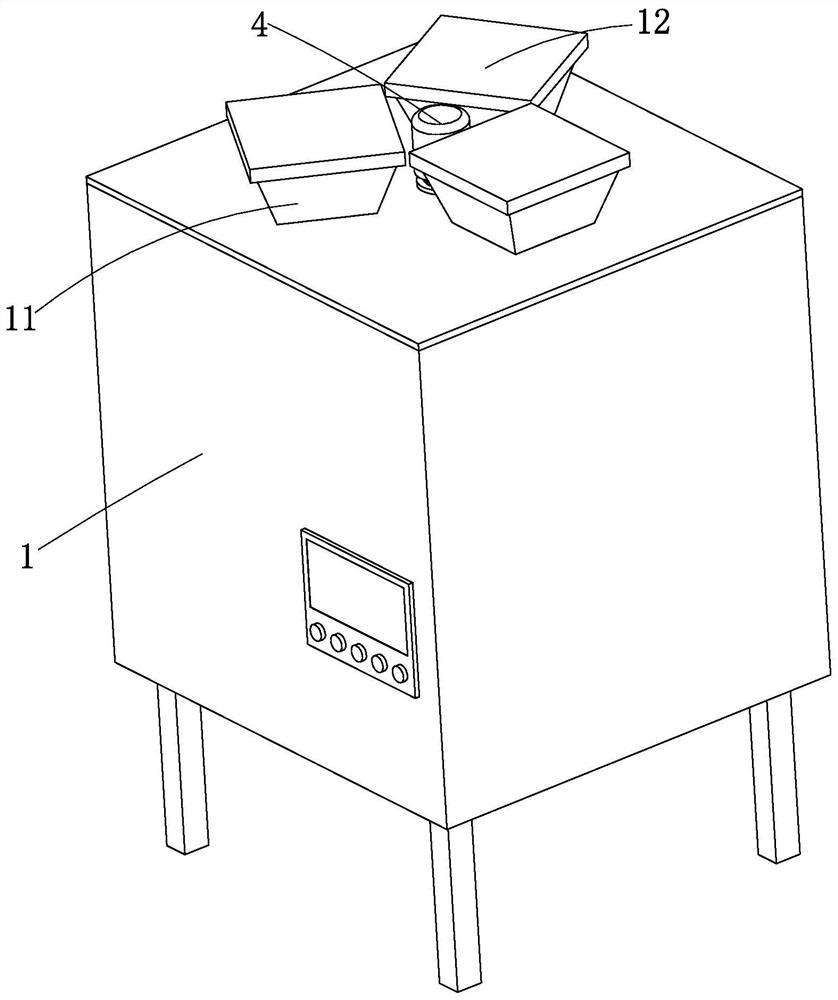

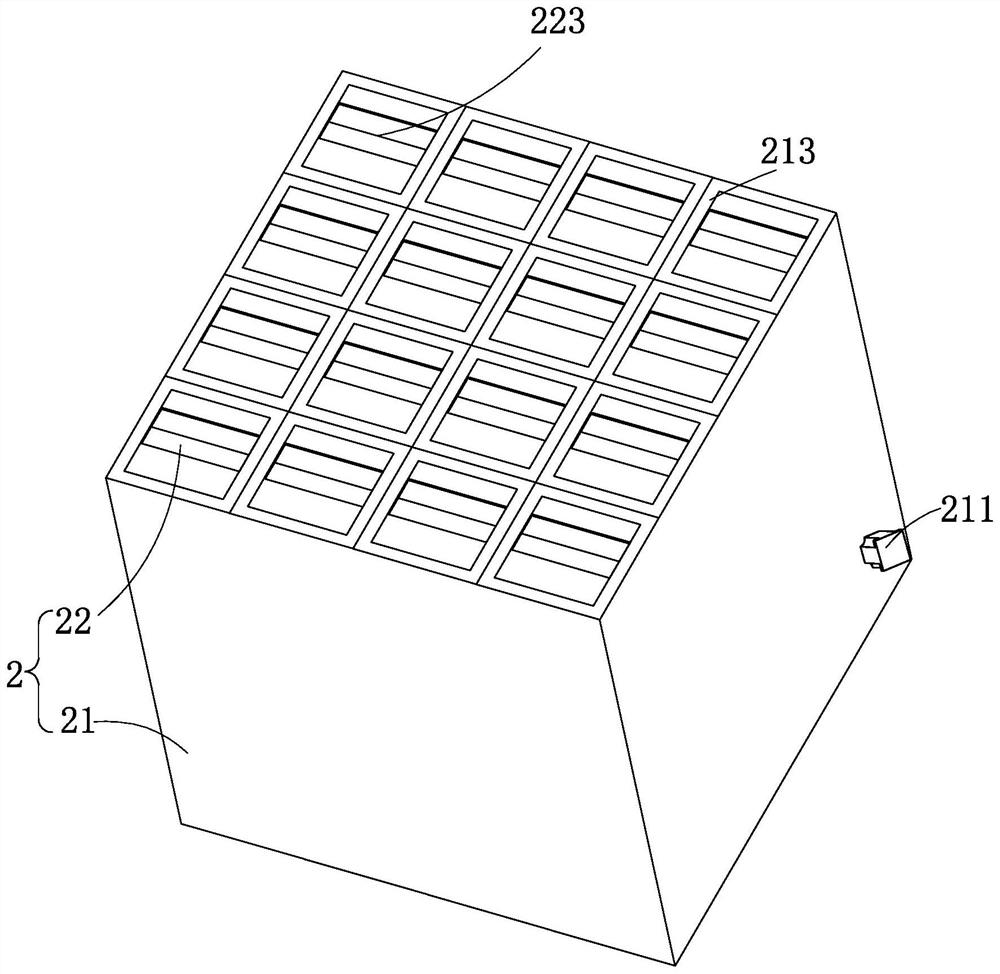

[0034] The embodiment of the present application discloses a permeable brick adobe raw material mixing and stirring equipment. refer to figure 1 and figure 2 , a permeable brick adobe raw material mixing and stirring equipment, including a body 1, a capacity mechanism 2 connected to the inside of the body 1 for carrying and measuring the quantity of raw materials, a stirring mechanism 4 connected to the body 1 for mixing raw materials, and a mixing mechanism 4 connected to the body Because of the discharge valve 5 that controls the discharge of the stirring mechanism 4, the feed port of the machine body 1 is connected with the feed port of the capacity mechanism 2, and the discharge port of the capacity mechanism 2 is connected with the feed port of the stir mechanism 4. When the user uses this When applying for raw material mixing, the raw materials are sent into the interior of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com