Anti-corrosion device for pipeline on-line film forming of oil refining and chemical engineering device

A technology for anti-corrosion devices and pipelines, which is applied in the direction of spraying devices and spray booths, etc. It can solve the problems of reducing the efficiency of anti-corrosion treatment, poor diffusion of film-forming liquid, and affecting the anti-corrosion effect of pipelines, so as to ensure the film-forming effect and avoid waste, efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

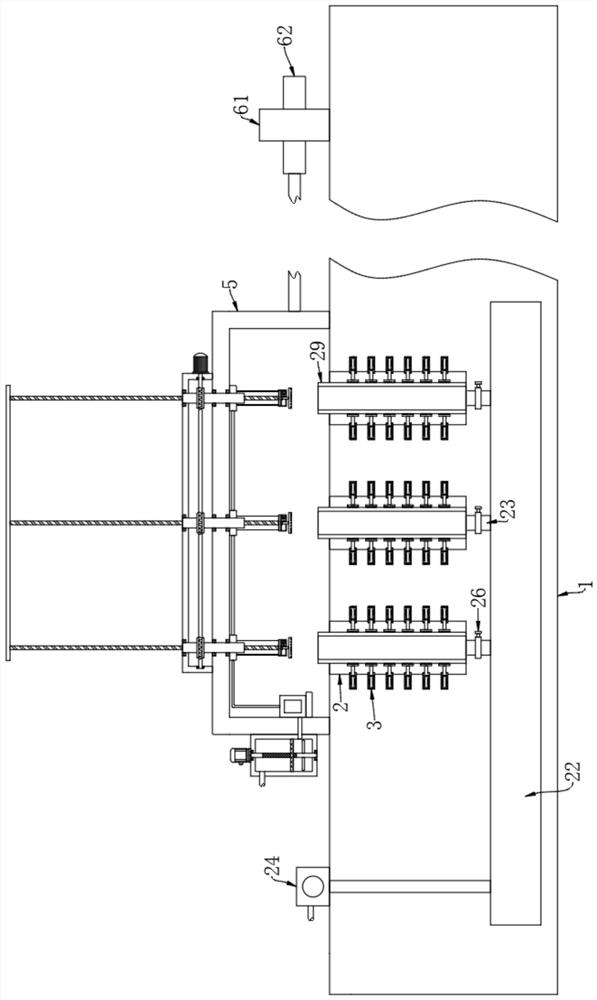

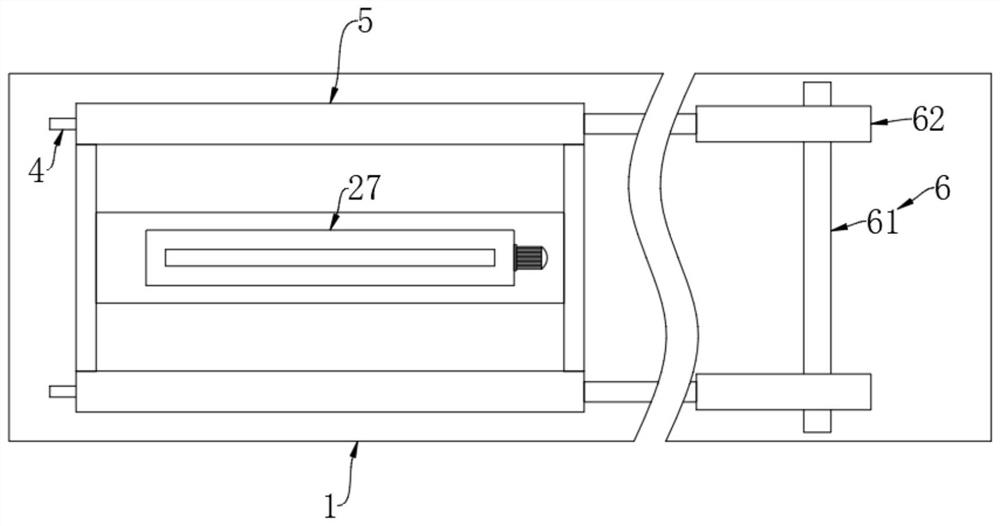

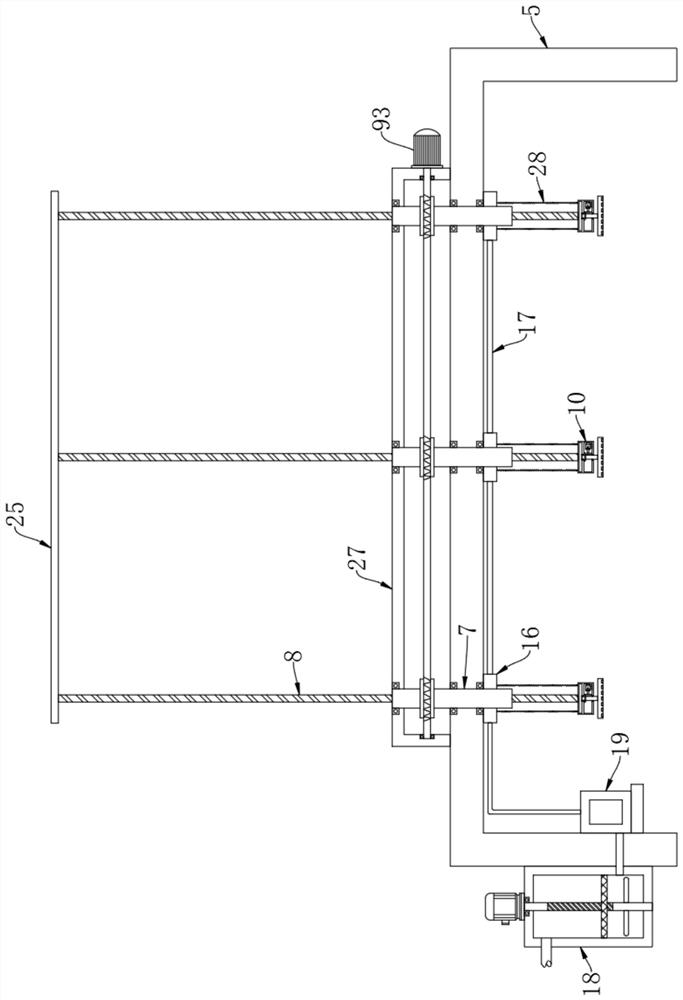

[0026] Such as Figure 1-7 As shown, an anti-corrosion device for online film formation of pipelines in oil refining and chemical plants includes a base 1 on which a plurality of pipeline grooves 2 are opened, and the inner walls of both sides of the pipeline grooves 2 are provided with a plurality of clamping Heating mechanism 3, clamping Heating mechanism 3 is composed of sliding sleeve 31, electromagnetic block 32, permanent magnet block 33, sliding rod 34, clamping block 35 and electric heating layer 36, sliding sleeve 31 is fixedly arranged on the inner wall of one side of pipeline groove 2 , and the electromagnetic block 32 is embedded in the sliding sleeve 31, the electromagnetic block 32 is fixedly connected with the permanent magnet block 33 through a plurality of return springs 20, the permanent magnet block 33 is slidingly connected with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com