A washing and drying device for ophthalmic medical tools

A technology for medical tools and drying devices, which is applied in the directions of drying, drying machine, and drying gas arrangement, can solve the problems of cumbersome process, time-consuming and labor-intensive, affecting the service life of medical tools, etc., and achieves easy cleaning and use process. Simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

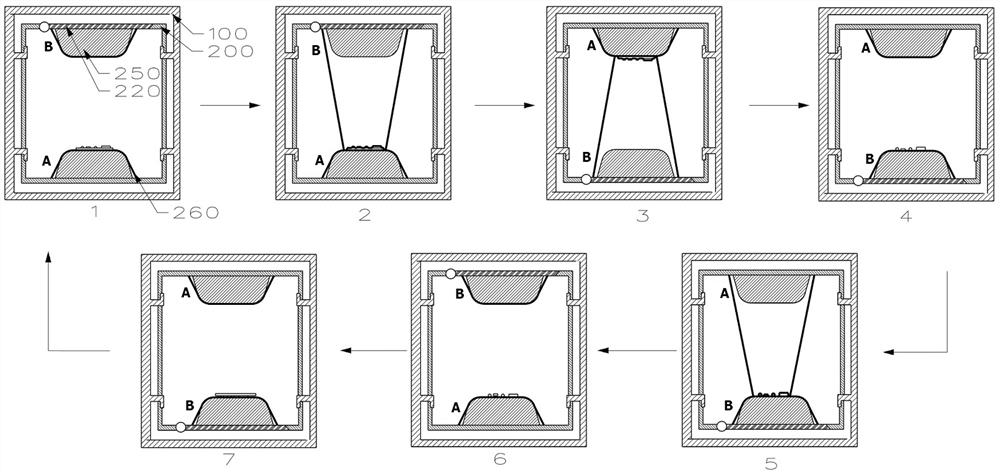

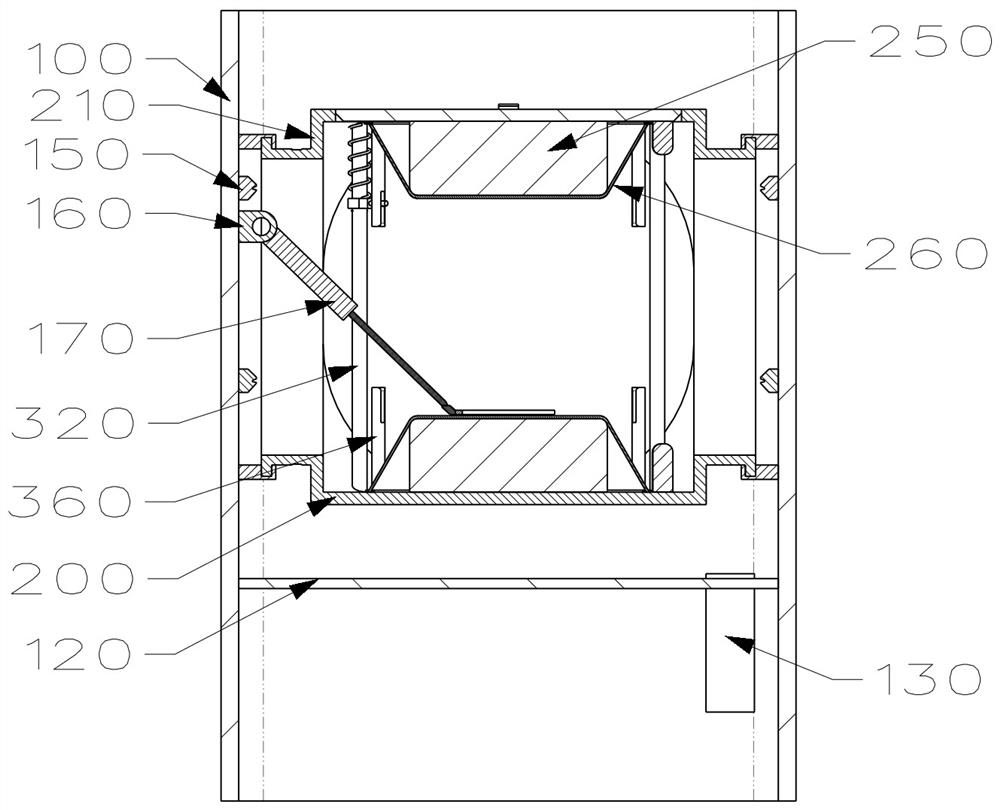

[0076] Such as Figure 1 to Figure 7 As shown, the cleaning and drying device for ophthalmic medical tools of the present application includes an outer casing assembly 100, an inner casing assembly 200, a power assembly and a control unit; the outer casing assembly 100 is a box structure, which serves to accommodate the inner Functions of the housing assembly 200; the inner housing assembly 200 includes an inner housing main body 210, which is located inside the outer housing assembly 100 and is a box structure with two sides and top openings.

[0077] Such as Figure 1 to Figure 3 As shown, the outer casing assembly 100 includes an outer casing main body, which is a tubular structure with upper and lower ends open, and its own height direction is the same as its own axial direction; an upper cover 110, Partition plate 120, liquid discharge channel 130, inner housing positioning assembly 140, spray head 150, manipulator positioning assembly 160 and shifting manipulator 170; s...

Embodiment 2

[0111] During the trial production of the cleaning and drying device in Embodiment 1, it was found that the liquid and gas ejected from the nozzle 150 may (due to the impact on the medical instruments being sterilized) cause the medical instruments placed on the platform 250 to deviate from their original positions, resulting in the appearance of medical instruments. The problem that the entire disk cannot be taken out after cleaning and drying (the probability of this situation is low but there is a possibility); in order to eliminate the above problems, the embodiment of this application adds a positioning net assembly 300 and a displacement guide on the basis of the above embodiments Column 320; specifically:

[0112] Such as Figure 5 , Figure 8 and Figure 9 As shown, the positioning net assembly 300 is positioned inside the inner casing main body 210, and the number is two. The two positioning net assemblies 300 are arranged opposite to each other to prevent the medic...

Embodiment 3

[0125] Considering that some ophthalmic medical instruments are relatively sharp (such as oblique tweezers), when using the cleaning and drying device in the above embodiment to clean and disinfect such medical instruments, it is easy to damage the rubber membrane 261, even if it can be added The thickness of the rubber film 261 prevents the rubber film 261 from being punctured to avoid the occurrence of air leakage, and it is impossible to avoid sharp medical equipment from damaging the rubber film 261 and thus affecting the service life of the cleaning and drying device; in view of the above problems, the present application implements Example On the basis of the above-mentioned embodiment, a partition cloth laying assembly 400 is added, and the direct contact between the medical device and the rubber film 261 in the disinfection process is avoided by laying the partition cloth 410; specifically:

[0126] Such as Figure 13 and Figure 14 As shown, the separation cloth layi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com