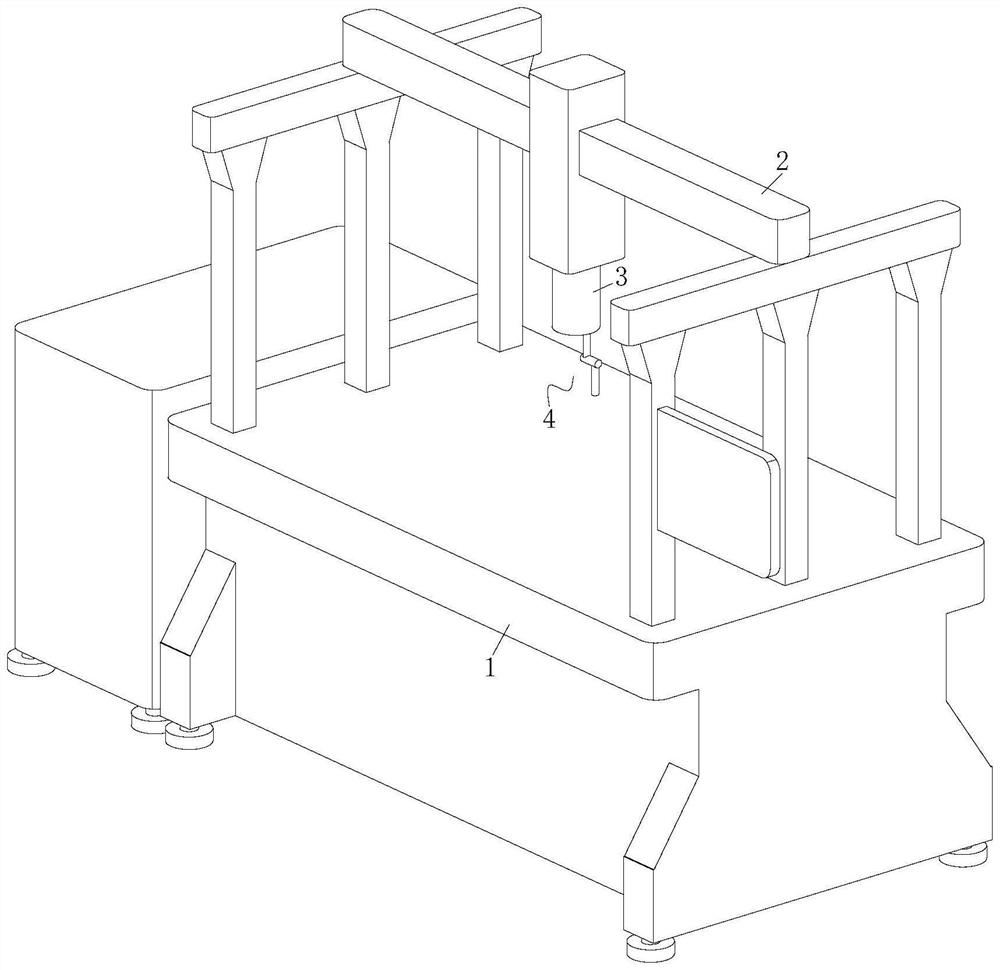

Longmen continuous galvanometer laser welding machine

A laser welding machine, gantry technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of vibration offset, danger, low efficiency of manual support and inconvenience, to enhance the scope of application and improve welding efficiency , Improve the effect of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

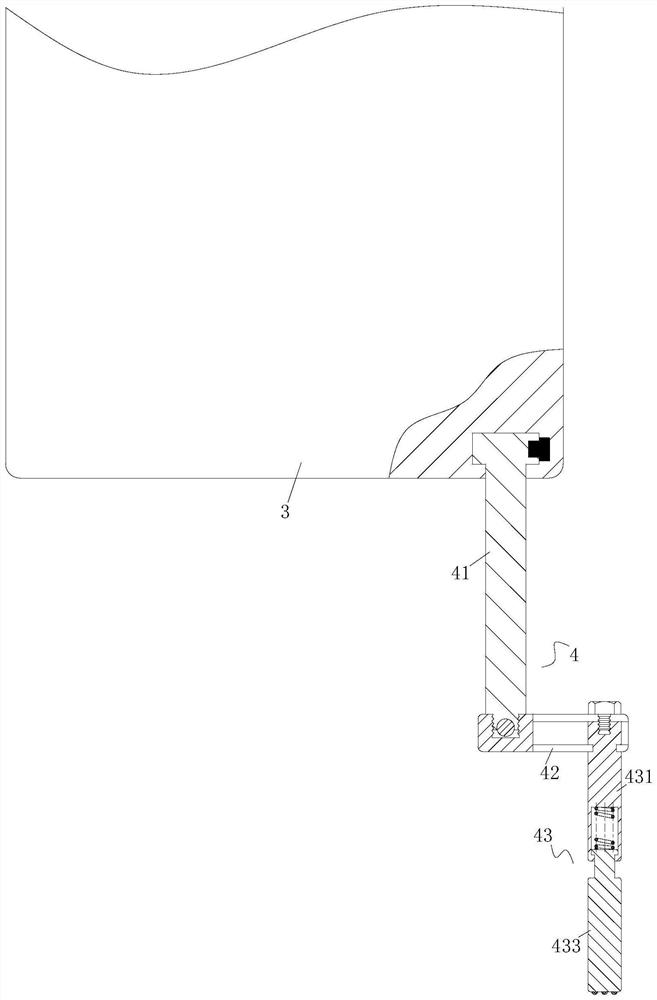

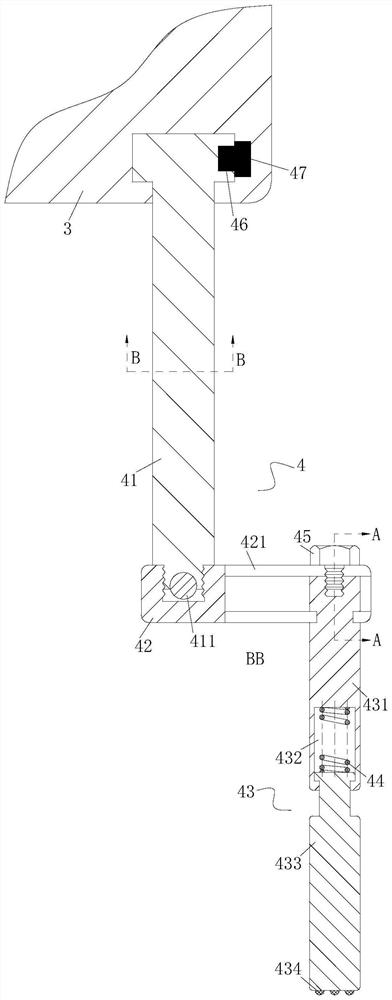

[0049] As an embodiment of the present invention, the supporting portion 4 includes

[0050] a rotating rod 41, the rotating rod 41 is placed vertically, and one end of the rotating rod 41 is rotatably connected to the lower end of the laser transmitter 3;

[0051] a connecting rod 42, the connecting rod 42 is placed horizontally, the connecting rod 42 is located at the lower part of the rotating rod 41 and is connected with the other end of the rotating rod 41;

[0052] pressing rod 43, the pressing rod 43 is placed vertically, the pressing rod 43 is located at the lower part of the connecting rod 42 and is connected to one end of the connecting rod 42;

[0053] The pressing rod 43 includes

[0054] an upper pressing rod 431, the upper end of the upper pressing rod 431 is connected to the connecting rod 42;

[0055] a lower pressing rod 433, the lower pressing rod 433 is located below the upper pressing rod 431 and is rotatably connected with the upper pressing rod 431;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com