Process method for improving machining efficiency of jet sheet

A process method and a technology of processing efficiency, applied in the field of mechanical processing, can solve the problems of insufficient equipment of slow wire-feeding machine tools, and achieve the effects of solving insufficient equipment of machine tools, ensuring machining accuracy and consistency, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] This part is the embodiment of the present invention, which is used to explain and illustrate the technical solution of the present invention.

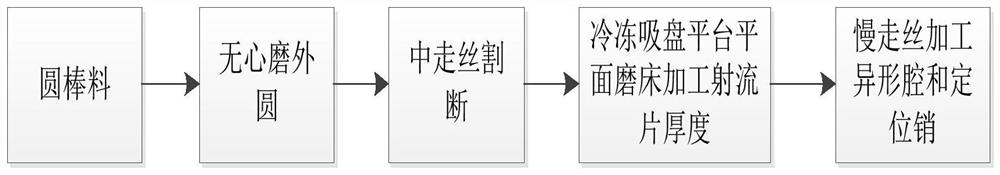

[0033] A process method for improving the processing efficiency of jet sheet, comprising the following steps:

[0034] Step 1, preparing a jet sheet rough machining blank to obtain a round bar;

[0035] Step 2, the round bar is processed to the theoretical size by a centerless grinder, and cut into thin slices of 0.8-0.8mm by wire;

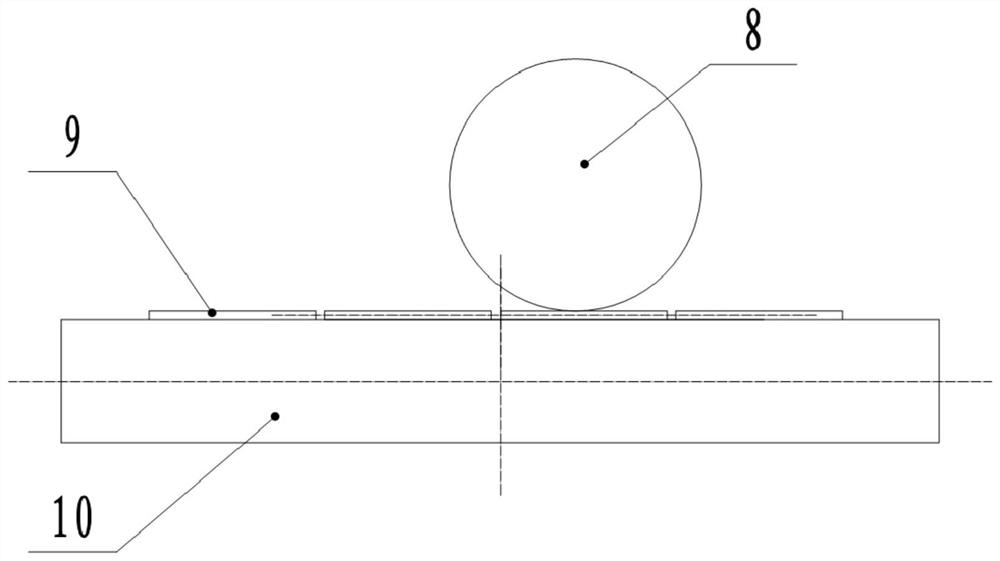

[0036] Step 3, processing the sheet on a surface grinder with a frozen suction cup platform, so that the flatness of the upper and lower surfaces of the sheet is within 0.002;

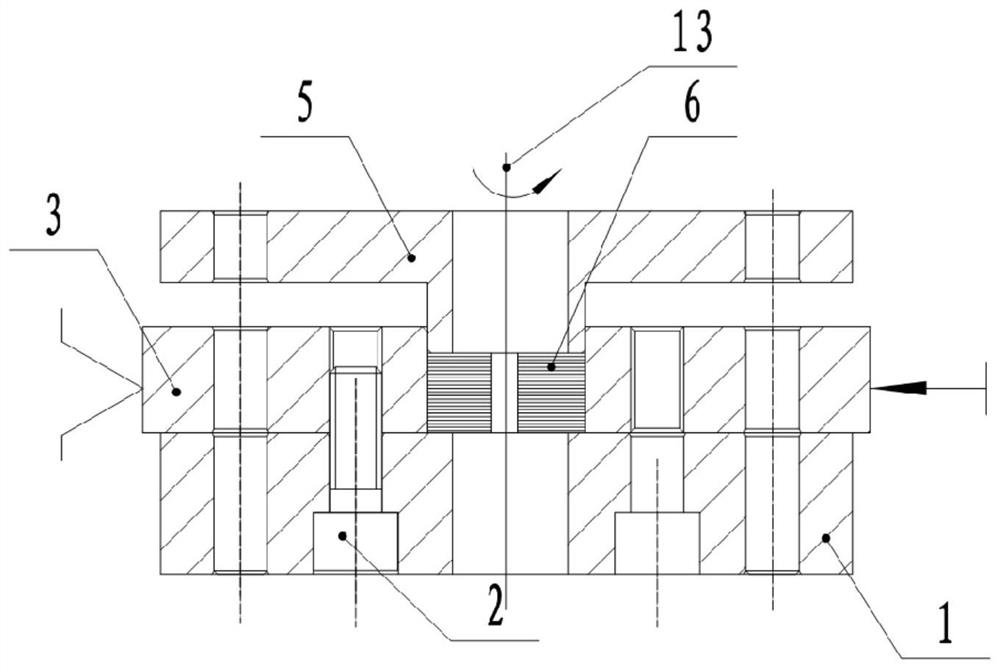

[0037] Step 4: Put several thin sheets into the jet sheet fixture by overlapping and combining them, and combine and process the special-shaped cavity and positioning pin hole of the jet sheet.

[0038] The threading hole of the jet sheet is processed before the heat treatment of the jet sheet rough blank.

[0039] In st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com