Grinding machine

A technology of grinding machine and bed, applied in the field of grinding machine, can solve the problems of affecting processing efficiency, long downtime of grinding machine, cumbersome and other problems, and achieve the effect of improving processing efficiency, reducing downtime of grinding machine and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

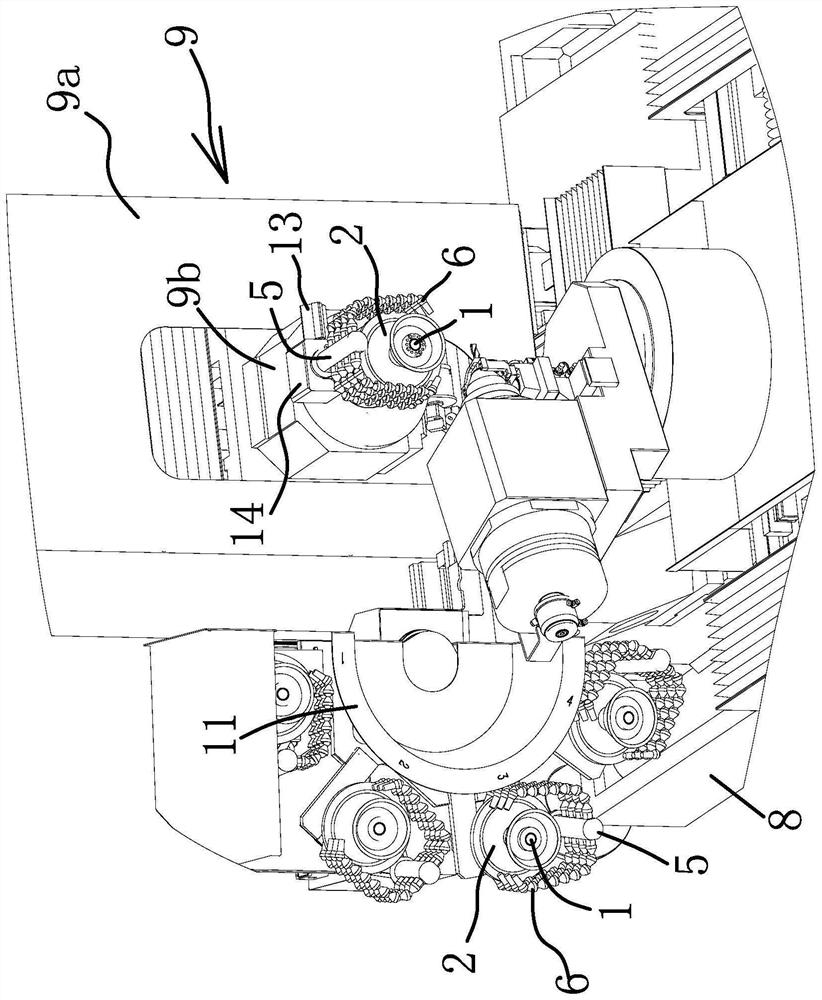

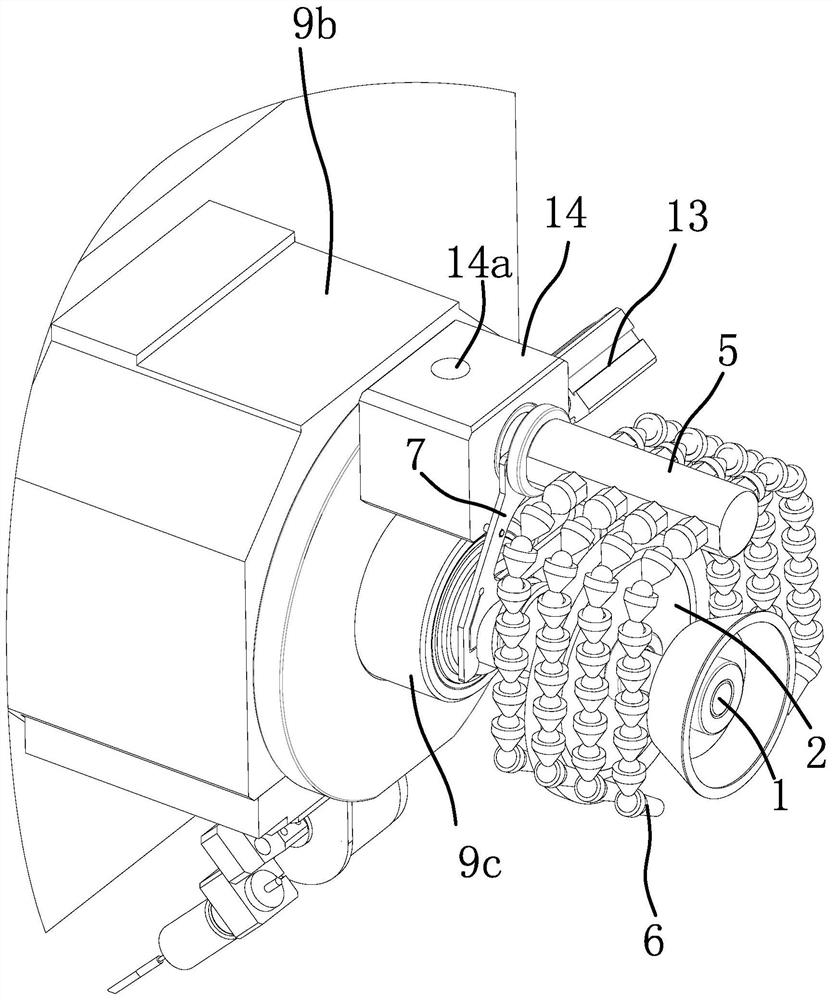

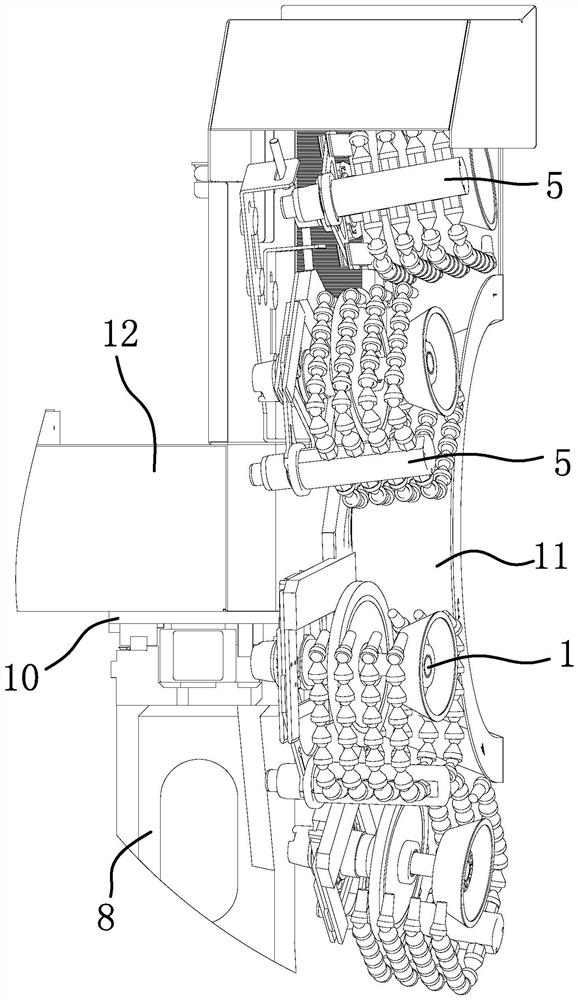

[0034] like figure 1 As shown, the grinding machine includes a bed 8 , a grinding wheel assembly and a headstock 9 arranged on the bed 8 .

[0035] Specifically,

[0036] The headstock 9 includes a case 9a that slides forward and backward on the bed 8, a spindle seat 9b that slides up and down on the case 9a, and a spindle 9c that is horizontally provided on the spindle seat 9b. Among them, the chassis 9a is arranged on the bed 8 through the cooperation and sliding of the guide rail slider, and automatically moves back and forth through the motor screw transmission mechanism or the cylinder or the oil cylinder; Motor lead screw transmission mechanism or cylinder or oil cylinder drive move up and down automatically;

[0037] like figure 1 and image 3 As shown, the left side of the main shaft 9c is provided with a support 10, and the support 10 is provided with a turntable 11 and a motor 12 for driving the turntable 11 to rotate around its own axis. The body 8 is provided ...

Embodiment 2

[0053] The structure and principle of the second embodiment are basically the same as the first embodiment, the difference is that the plug-in structure includes a cylinder formed on the outer wall of the closed end of the water pipe 5 and a pipe formed on the support plate 3, the cylinder The shape and size of the cylinder are matched with the pipe body, and the cylinder is snapped into the pipe body.

Embodiment 3

[0055] The structure and principle of the third embodiment are basically the same as those of the first embodiment, except that the seal 15 is an annular rubber pad, and the bottom wall of the large hole 14c is provided with an annular groove 2 for placing the annular gasket, and the annular seal The two end surfaces of the pad are respectively pressed on the second bottom wall of the annular groove and the end surface of the annular shoulder 5b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com