A grinding carrier, a grinding device, a grinding method, and a silicon wafer

A technology of grinding device and grinding method, which is applied in the fields of grinding method, silicon wafer, grinding device, and grinding carrier, which can solve the problems of grinding waste liquid overflow, downtime, and complicated installation, so as to save installation space and reduce secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

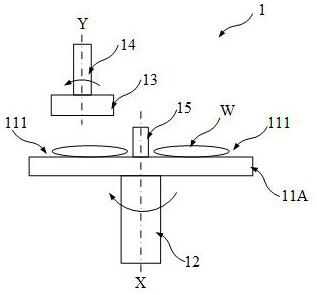

[0033] see figure 1 , which shows a schematic structural diagram of the existing grinding device 1 . like figure 1 As shown, the grinding device 1 mainly includes:

[0034] The grinding stage 11A is used to carry the silicon wafer W;

[0035] The first driving mechanism 12 is used to drive the grinding stage 11A to rotate around the first axis X during the grinding process;

[0036] The grinding head 13 is used for grinding the surface of the silicon wafer W;

[0037] The second driving mechanism 14 is used to drive the grinding head 13 to rotate around the second axis Y during the grinding process.

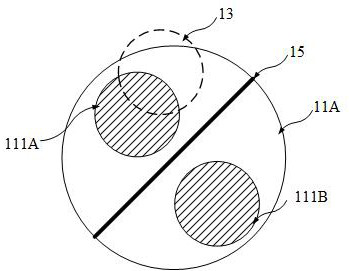

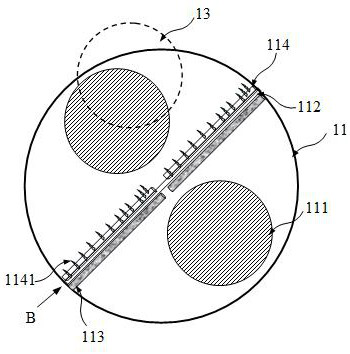

[0038] It should be noted that if figure 2 As shown, the grinding stage 11A is provided with a plurality of carrying trays 111 , and each carrying tray 111 can ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com