Physical cutting method for magnetic base material

A magnetic base material and cutting method technology, which is applied in the direction of stone processing tools, stone processing equipment, inductance/transformer/magnet manufacturing, etc., can solve the problems of not being suitable for large-scale production, low product qualification rate, and large chipping size. Achieve the effect of improving cutting quality, reducing cost and reducing edge chipping size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

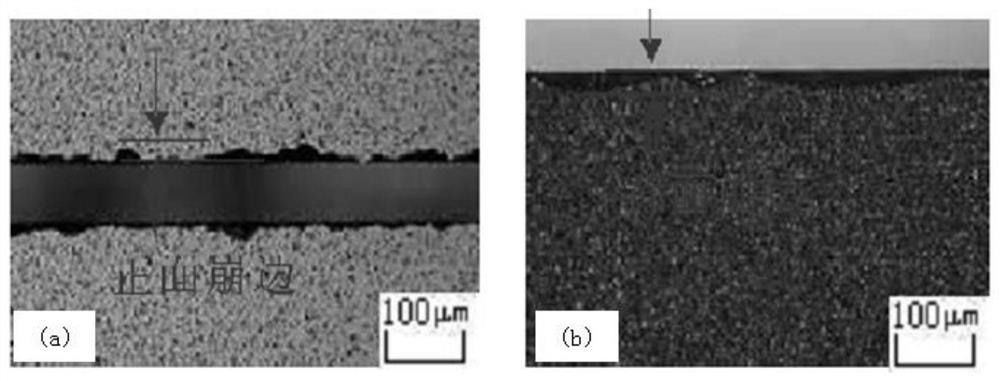

[0037] Based on a microwave ferrite substrate with a thickness of 0.4mm, adopt a cutting method, set different cutting parameters, measure the size of chipping on the front and back sides, and randomly measure 5 data as shown in Table 1. The cutting effect diagram is as follows figure 2 shown. When the tool is cutting, the spindle speed of the cutting machine is 28000 rpm, and the cutting depth is 0.42mm.

[0038] Table 1 The effect of different cutting speeds on the chipping of the front and back sides of the substrate

[0039]

Embodiment 2

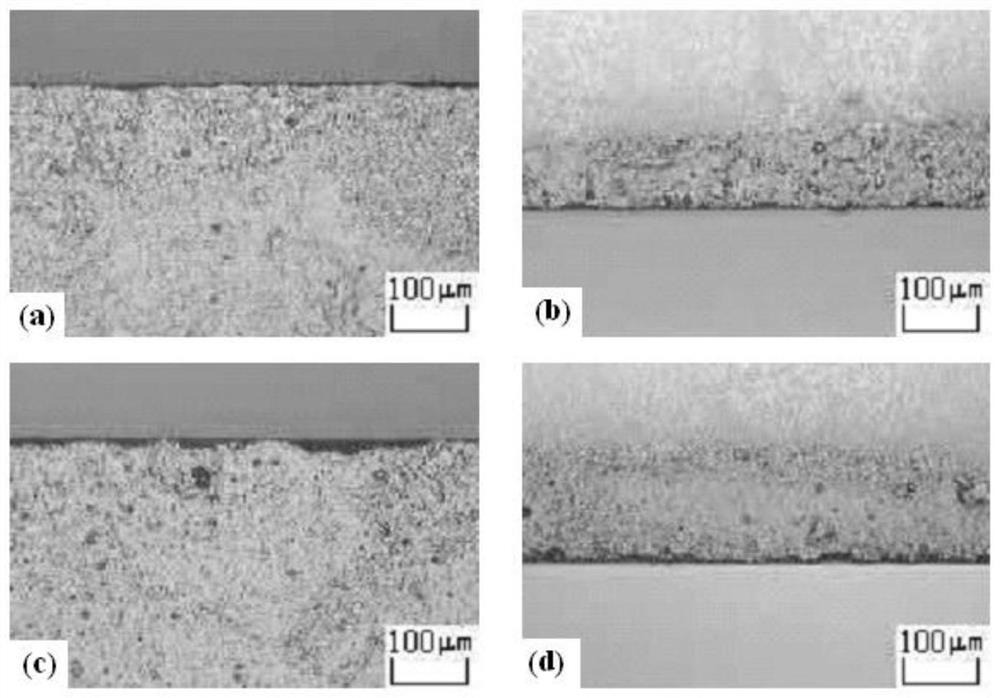

[0041] Based on a microwave ferrite substrate with a thickness of 1.0mm, adopt a cutting method, set different cutting parameters, measure the size of chipping on the front and back sides, and randomly measure 5 data as shown in Table 2. The cutting effect diagram is as follows image 3 shown. When the tool is cutting, the spindle speed of the cutting machine is 30,000 rpm, and the cutting depth is 1.02mm.

[0042]Table 2 The effect of different cutting speeds on the chipping of the front and back sides of the substrate

[0043]

Embodiment 3

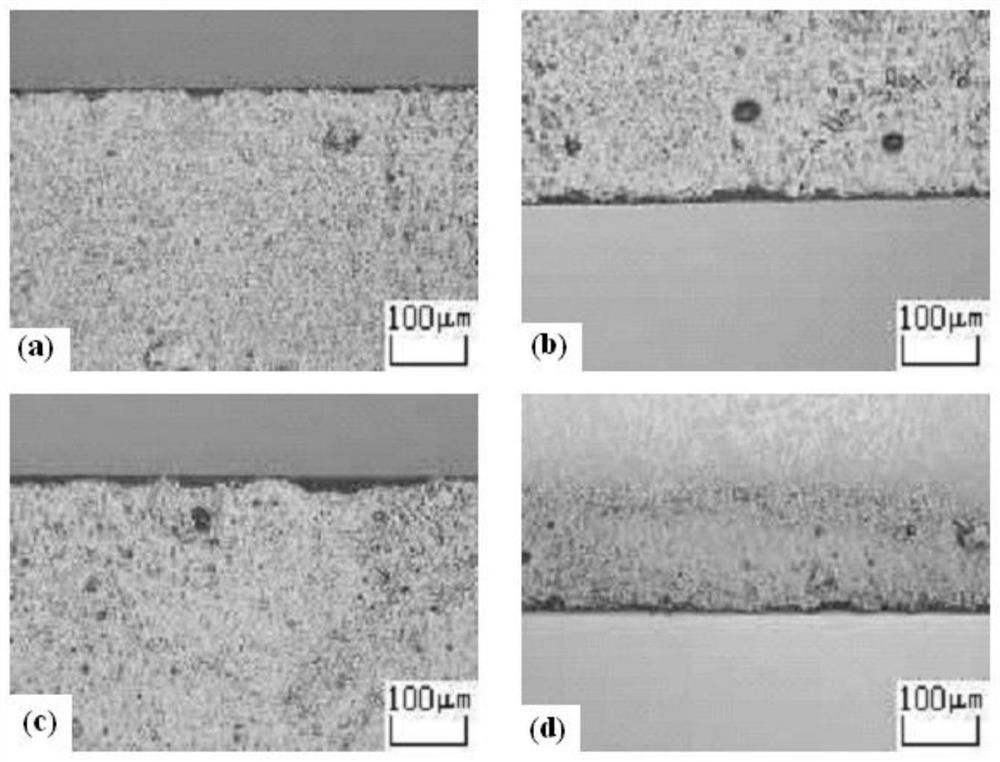

[0045] Based on a microwave ferrite substrate with a thickness of 1.5mm, adopt a one-time cutting method, set the cutting speed at 1.0mm / s, measure the edge chipping size of the front and back sides, and randomly measure 5 data as shown in Table 3. The cutting effect Figure such as Figure 4 shown. When the tool is cutting, the spindle speed of the cutting machine is 32000 rpm, and the cutting depth is 1.52mm.

[0046] Table 3 The effect of 1.0mm / s cutting speed on the edge chipping of the front and back of the substrate

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com