Coal mine transport vehicle capable of being braked and facilitating feeding and discharging

A technology for transport vehicles and coal mines, applied in the field of transport vehicles, can solve the problems of long time, increased transportation difficulties, consumption, etc., and achieve the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

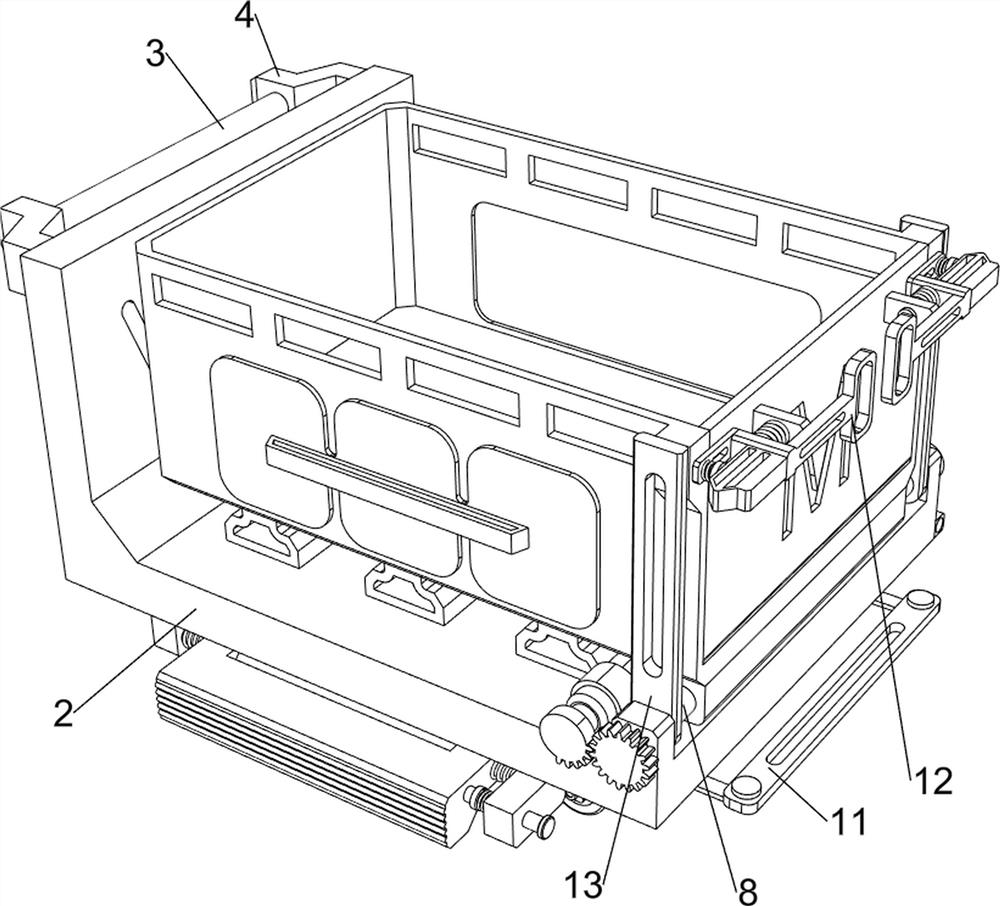

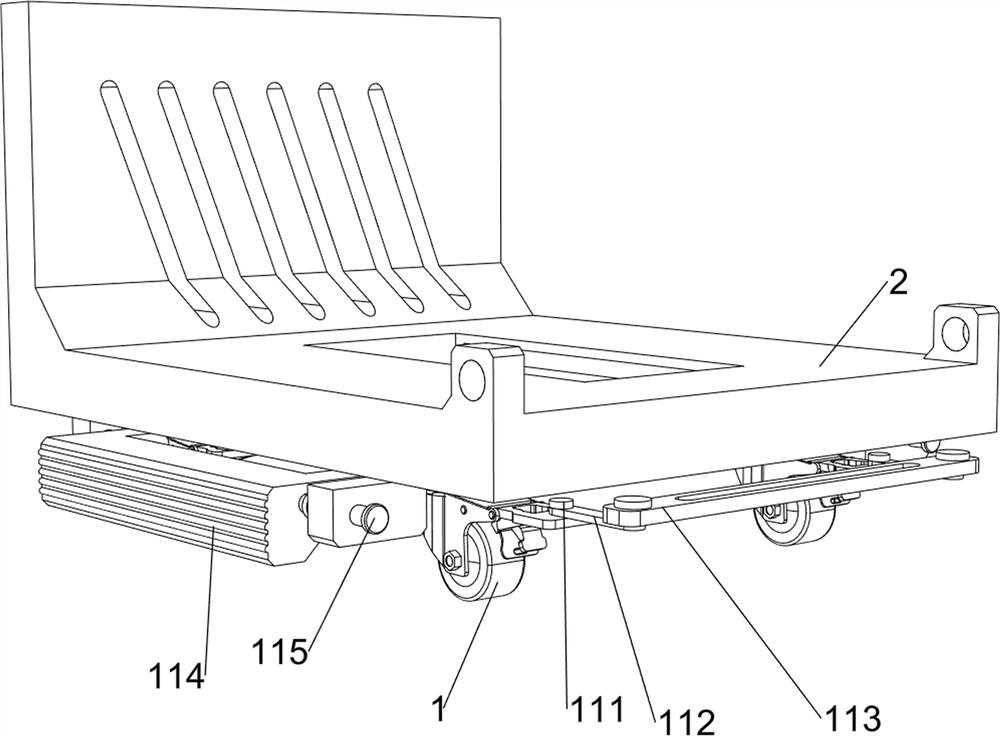

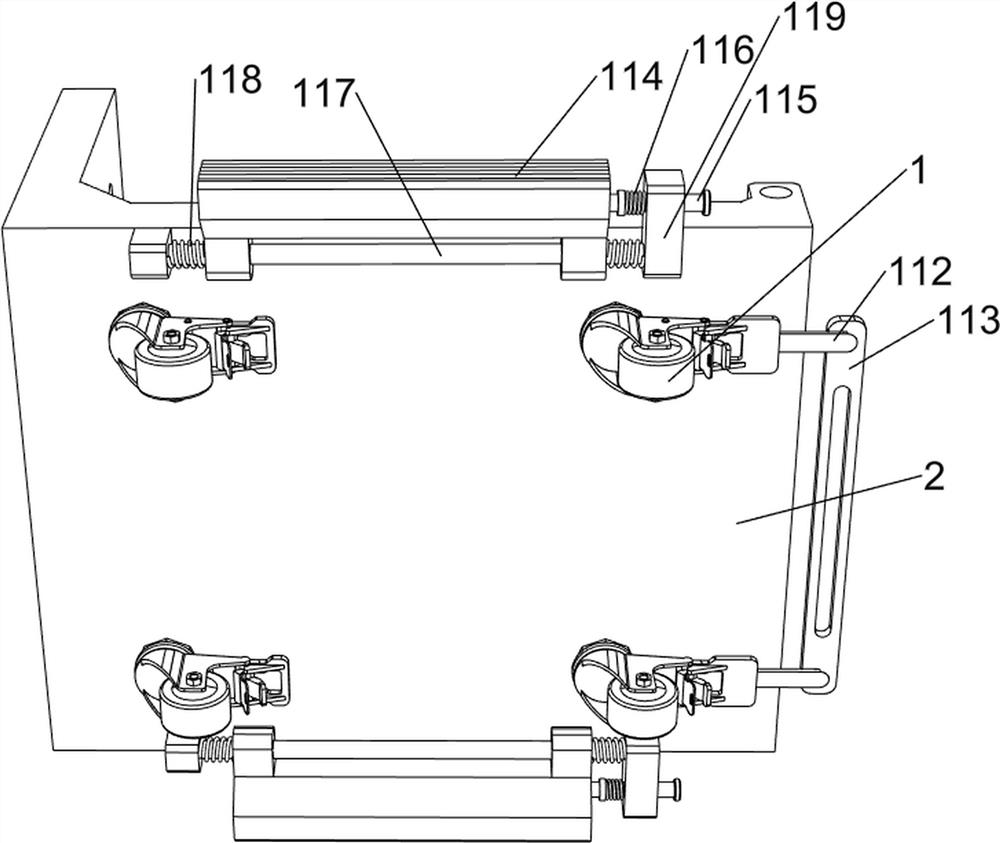

[0032] A kind of coal mine is convenient for loading and unloading and can brake the transport vehicle, such as Figure 1-7 As shown, it includes a universal wheel 1, a bottom plate 2, a first fixed block 3, a pull handle 4, a coal basket 5, a first end cover 6, a second end cover 7, an unloading mechanism 8 and a loading mechanism 9, and the bottom plate The left and right sides of the lower part of 2 are connected with universal wheels 1 in a rotationally symmetrical manner, and the upper left side of the base plate 2 is connected with a first fixed block 3 symmetrically front and rear, and a pull handle 4 is connected between the first fixed blocks 3, and the base plate 2 is provided with a coal basket 5, the rear side of the coal basket 5 is detachably provided with a first end cover 6, and the front side of the coal basket 5 is detachably provided with a second end cover 7, and the coal basket 5 and the bottom plate 2 A blanking mechanism 8 is provided between them, and a...

Embodiment 2

[0039] On the basis of Example 1, such as figure 2 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, a locking mechanism 10 is also included, and the locking mechanism 10 includes a first clamping plate 101, a locking block 102, a second torsion spring 103, a slide block 104, a first guide rod 105 and a first spring 106, the shovel The left side of coal plate 93 is connected with the first clamping plate 101, and bottom plate 2 left rear side is connected with the first guide bar 105, and the first guide bar 105 is slidably connected with slide block 104, and the upper side of slide block 104 is connected with the first guide bar 105. A first spring 106 is connected between the tops of a guide rod 105, and a locking block 102 is connected to the rear side of the slide block 104 in a rotational manner, and a second torsion spring 103 is connected between the locking block 102 and the slide block 104, and the locking block 102 cooperates with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com