Automatic wool removing device for textile fabric

An automatic technology for textile fabrics, applied in the field of fabrics, can solve the problems of fabric damage, fabric entanglement, material waste, etc., and achieve the effects of stable and firm fixation, guaranteed cleaning quality, and improved disassembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

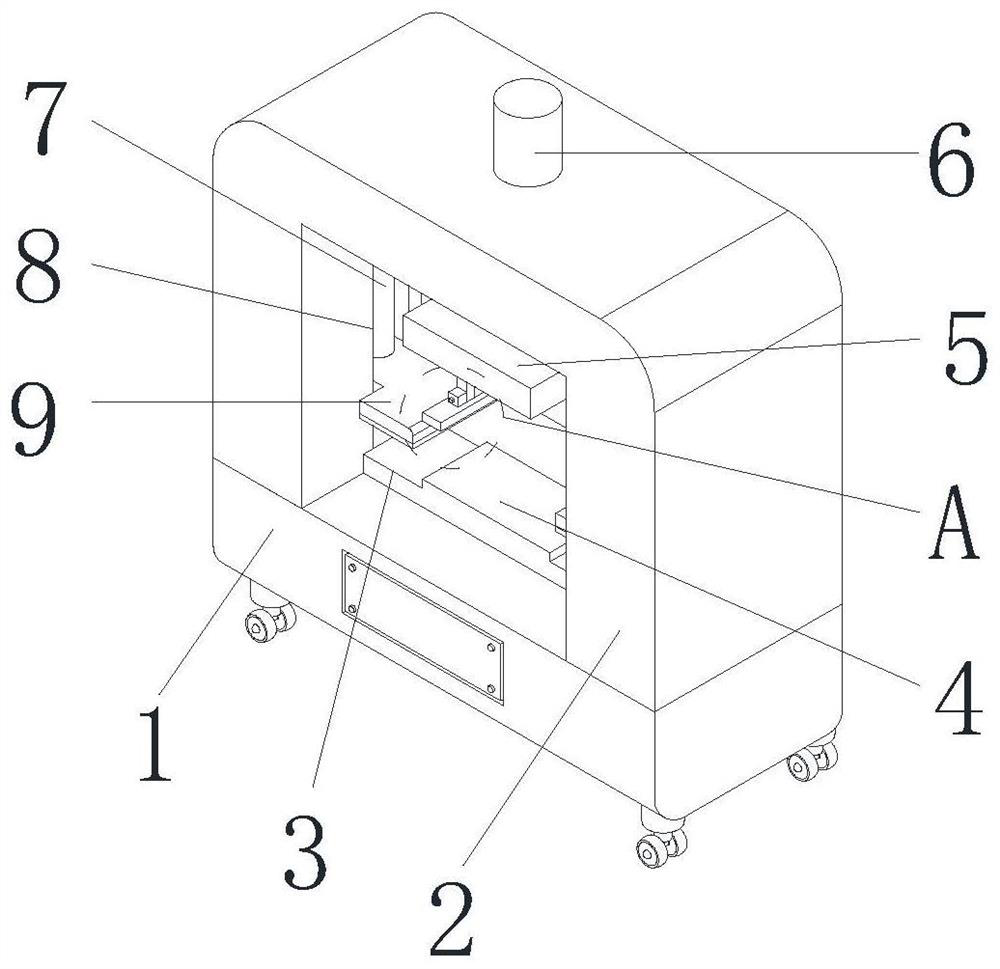

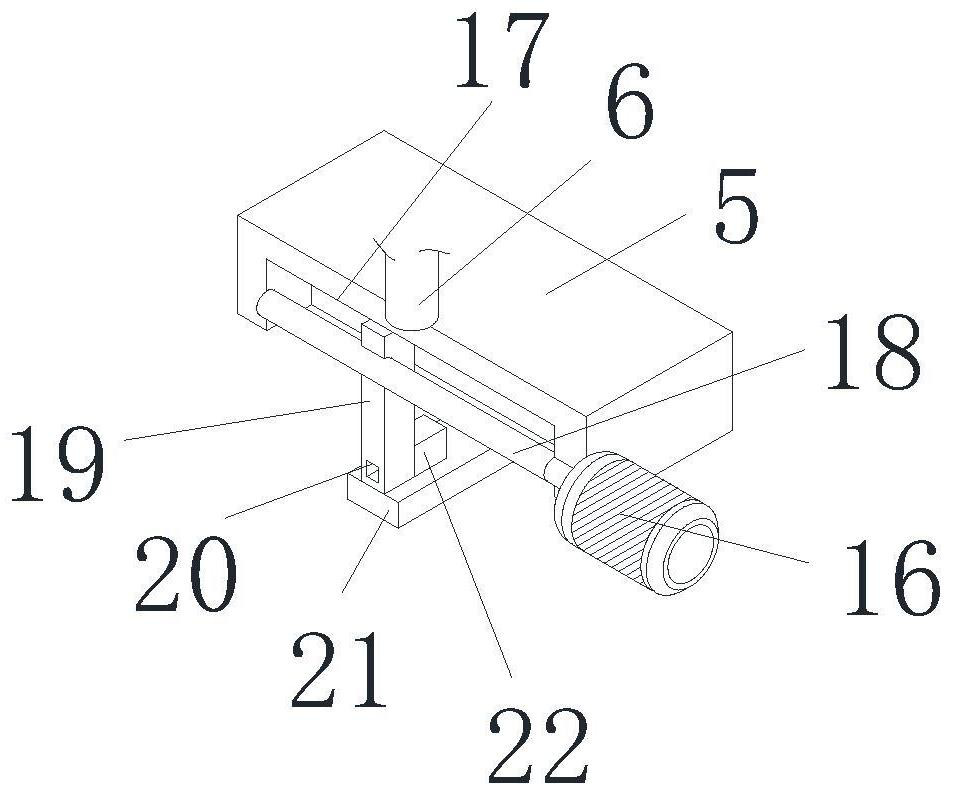

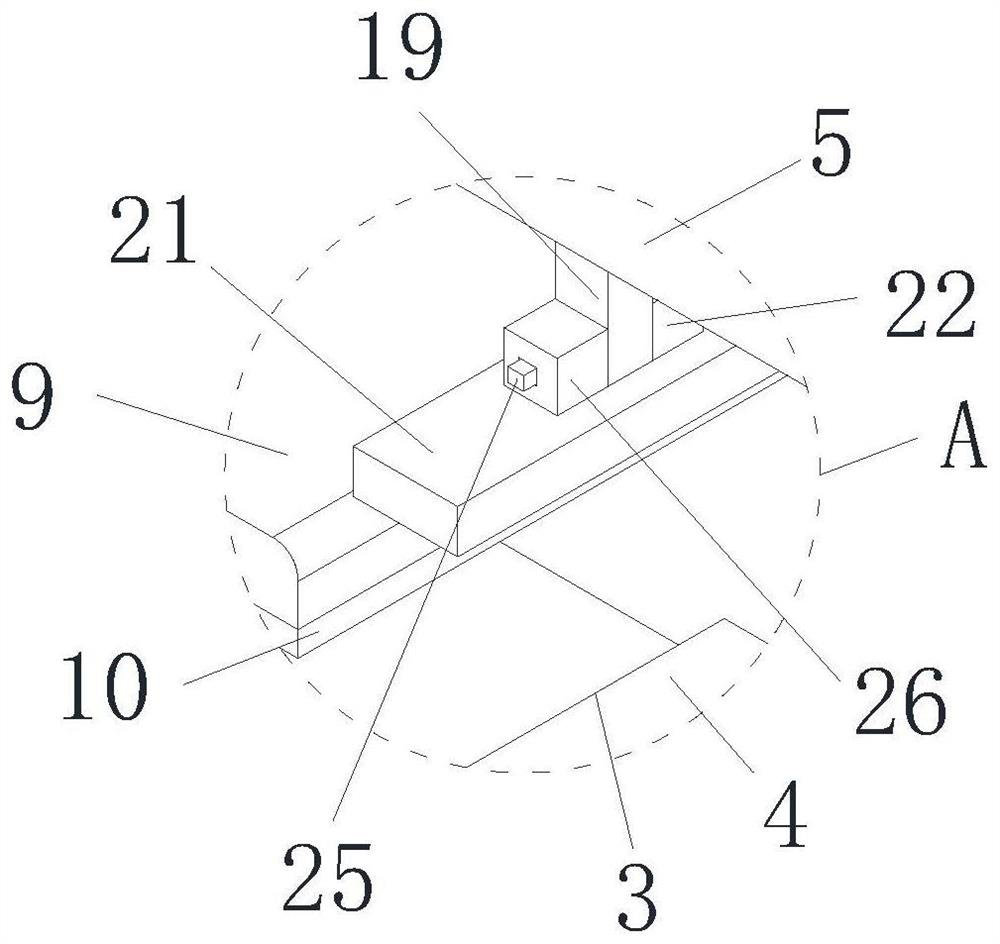

[0027] see Figure 1-3 , the present invention provides a technical solution: an automatic delinting device for textile fabrics, comprising a base 1, the top of the base 1 is fixedly connected to a support frame 2, the support frame 2 is in the shape of a vertical 匚, and the inside of the vertical plate of the support frame 2 is Hollow structure, the top of the base 1 is fixedly connected with a workbench 4, and the top of the workbench 4 is provided with two mirrored positioning grooves 3, the top of the workbench 4 can place textile fabrics, and the workbench 4 is located on the two vertical sides of the support frame 2. Between the boards, a cylinder 6 is fixedly connected to the top of the support frame 2. The cylinder 6 is an existing structure, so I won’t repeat it here. The output end of the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com