Flexible speed planning and displacement compensation method for laser cutting

A displacement compensation and laser cutting technology, applied in general control systems, program control, instruments, etc., can solve the problems of complex and cumbersome processes, inability to achieve efficient execution, etc., and achieve the effects of efficient execution, smooth and soft movements, and accurate precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

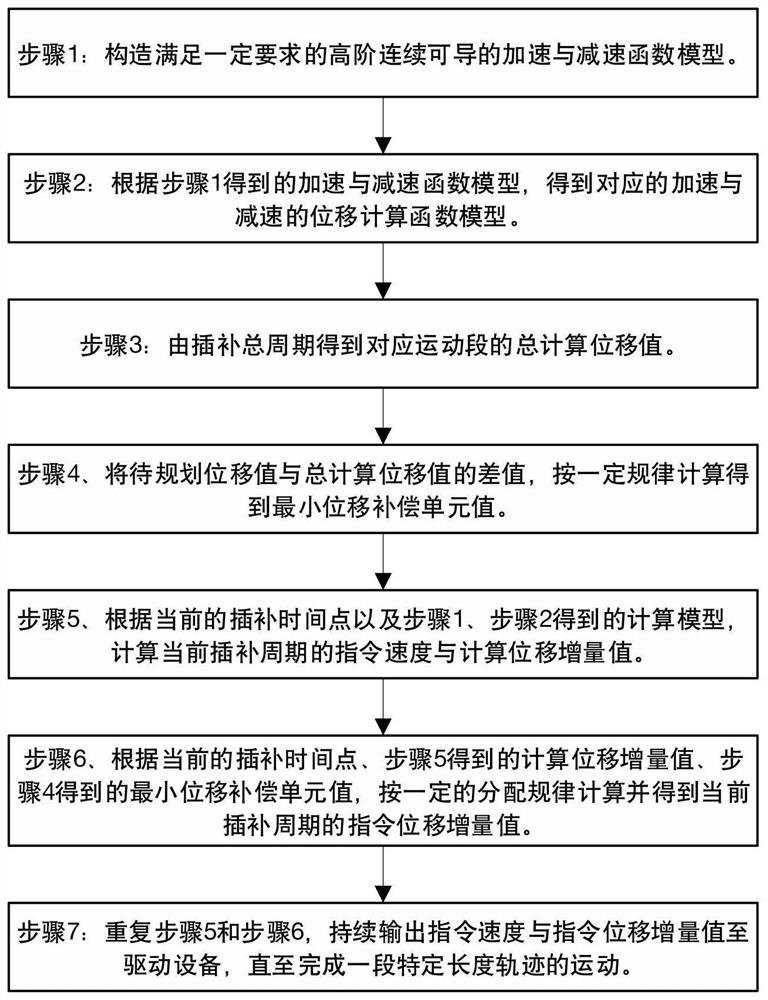

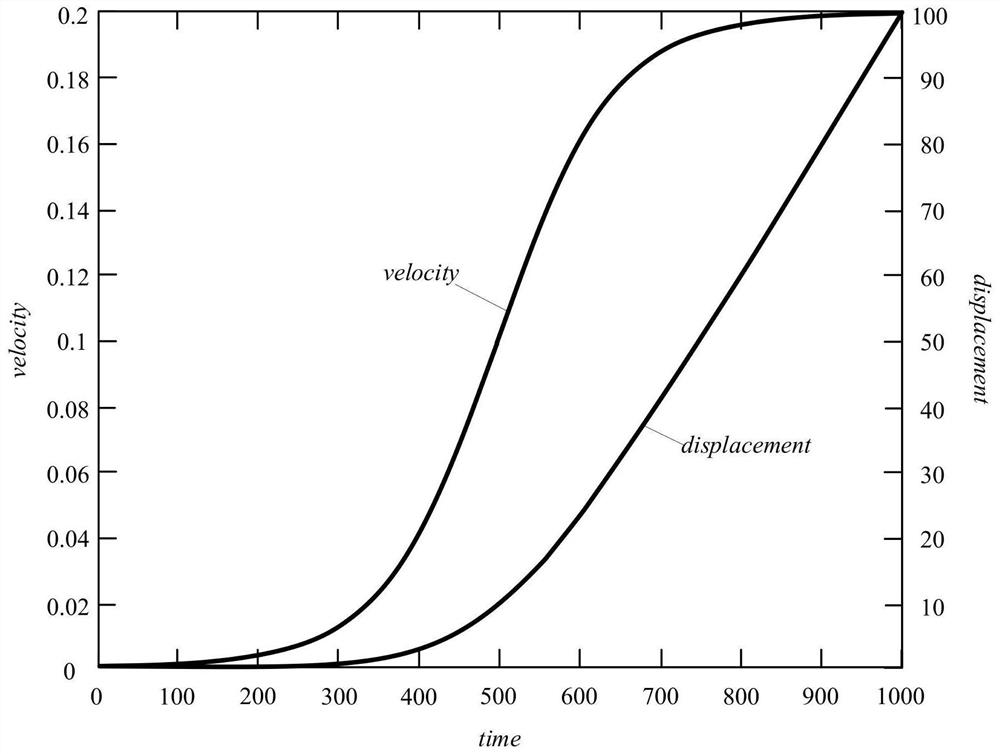

[0039] figure 1 Execution flow chart for the steps of the present invention, figure 2 It is a schematic diagram of the basic speed curve and its basic parameters of the present invention, image 3 Be the speed, displacement curve figure in the embodiment of the present invention, Figure 4 Be the acceleration graph in the embodiment of the present invention, as figure 1 , figure 2 , image 3 and Figure 4 A flexible speed planning and displacement compensation method for laser cutting is shown, and its specific implementation includes the following steps:

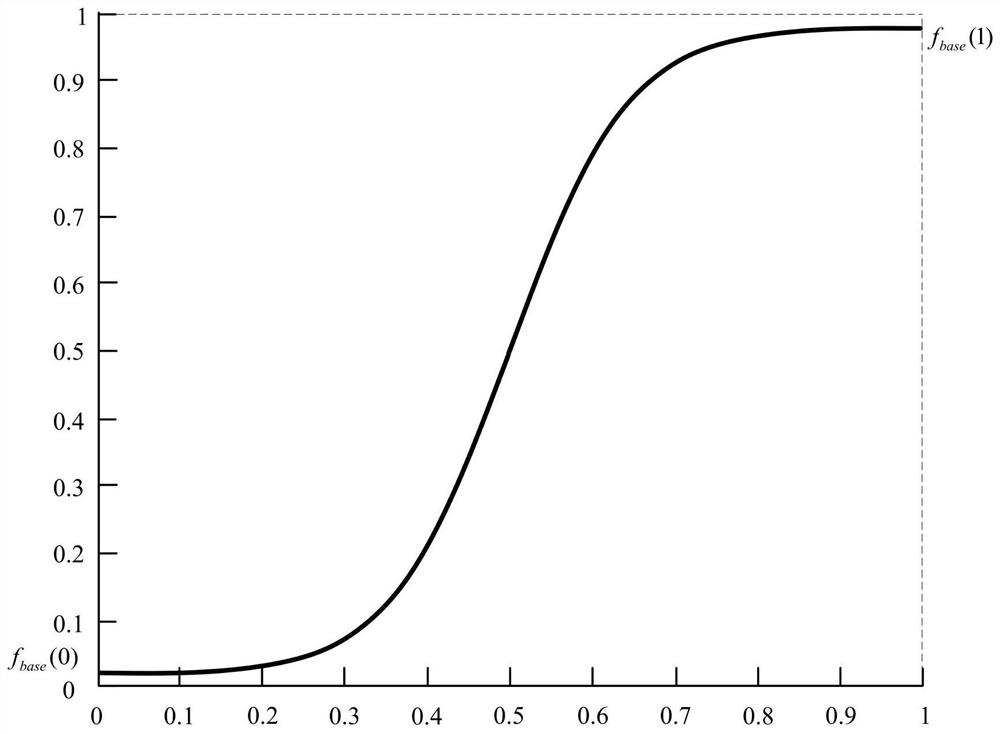

[0040] Step 1.1, construct the acceleration and deceleration function model, and ensure that the two functions meet certain requirements, namely: domain x∈[0,1], value range y∈[0,1], first define the acceleration and deceleration basic functions: where a is a calculation constant.

[0041] Step 1.1.1, constructing the acceleration function model: the acceleration function model in step S1 adopts

[0042] Step 1...

Embodiment 2

[0083] figure 1 Execution flow chart for the steps of the present invention, figure 2 It is a schematic diagram of the basic speed curve and its basic parameters of the present invention, image 3 Be the speed, displacement curve figure in the embodiment of the present invention, Figure 4 Be the acceleration graph in the embodiment of the present invention, as figure 1 , figure 2 , image 3 and Figure 4 A flexible speed planning and displacement compensation method for laser cutting is shown, and its specific implementation includes the following steps:

[0084] Step 1.1, construct the acceleration and deceleration function model, and ensure that the two functions meet certain requirements, namely: domain x∈[0,1], value range y∈[0,1], first define the acceleration and deceleration basic functions: where a is a calculation constant.

[0085] Step 1.1.1, constructing the acceleration function model: the acceleration function model in step S1 adopts

[0086] Step 1...

Embodiment 3

[0127] figure 1 Execution flow chart for the steps of the present invention, figure 2 It is a schematic diagram of the basic speed curve and its basic parameters of the present invention, image 3 Be the speed, displacement curve figure in the embodiment of the present invention, Figure 4 Be the acceleration graph in the embodiment of the present invention, as figure 1 , figure 2 , image 3 and Figure 4 A flexible speed planning and displacement compensation method for laser cutting is shown, and its specific implementation also includes the following steps:

[0128] First, consider an accelerated motion process, assuming the initial velocity v s =0, the target speed v tar =0.2, the maximum acceleration A during the acceleration process a =0.0007, the displacement value S to be planned plan =100.

[0129] Step 1. Construct a high-order continuously differentiable acceleration and deceleration function model that meets certain requirements. Preferably, the accele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com