LED packaging method and LED lamp

A technology of LED packaging and LED lights, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as color coordinate drift, and achieve the effects of reducing heat, avoiding color coordinate drift, and avoiding luminous flux reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

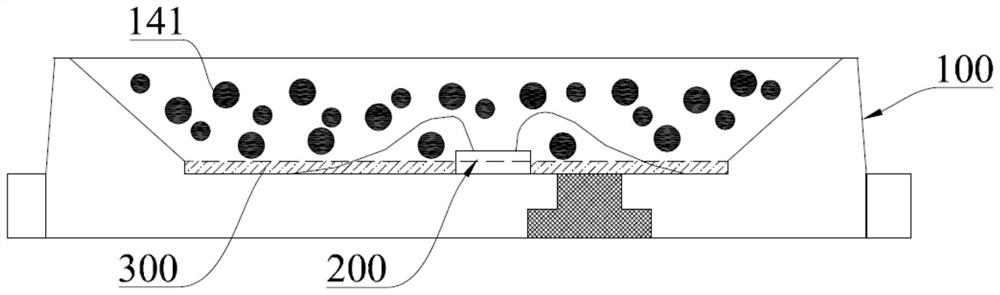

[0050] Please refer to Figure 5 and Figure 13 to Figure 16 , Embodiment 1 of the present invention is: an LED packaging method, which is applied to the production process of LED lamps and LED modules.

[0051] Described LED packaging method comprises the steps:

[0052] S11, providing a bracket 100 and at least one LED chip 200;

[0053] S12, fixing the LED chip 200 on the support 100 through the thermally conductive adhesive layer 110;

[0054] S13, performing wire bonding on the LED chip 200 and the bracket 100;

[0055] S14, setting the first silica gel layer 130 covering the LED chip 200 on the bracket 100;

[0056] S15 , disposing a second silica gel layer 140 mixed with fluorescent powder 141 on the first silica gel layer 130 .

[0057] The working principle of the LED packaging method in this embodiment is as follows: the LED chip 200 is fixed on the bracket 100 through the thermally conductive adhesive layer 110, and conducts heat to the bracket 100 when the LED...

Embodiment 2

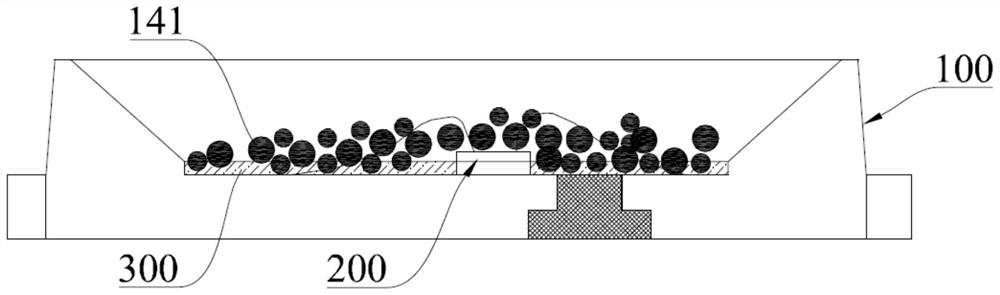

[0061] refer to Figure 6 to Figure 16 , Embodiment 2 of the present invention provides another specific implementation of the LED packaging method.

[0062] Described LED packaging method comprises the steps:

[0063] S20, providing a bracket 100 and at least one LED chip 200;

[0064] S21, fixing the LED chip 200 on the bracket 100 through the thermally conductive adhesive layer 110;

[0065] S22 , fixing the edge of the LED chip 200 on the bracket 100 through the transparent glue layer 120 .

[0066] S23, performing wire bonding on the LED chip 200 and the bracket 100;

[0067] S24, setting the first silica gel layer 130 covering the LED chip 200 on the bracket 100;

[0068] S25 , disposing a second silica gel layer 140 mixed with fluorescent powder 141 on the first silica gel layer 130 .

[0069] The working principle of the LED packaging method in this embodiment is as follows: the LED chip 200 is fixed on the bracket 100 through the thermally conductive adhesive lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com