An automatic plug-in device and calibration method for six-degree-of-freedom adaptive pose adjustment

A posture adjustment and automatic plug-in technology, which is applied in the direction of coupling devices, measuring devices, and two-part connecting devices, can solve the problems of high automation and reliability requirements, many connector channels, and easily damaged connectors. Achieve automation and high operational reliability, long-distance movement and high-precision docking, and realize the effect of flexible docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

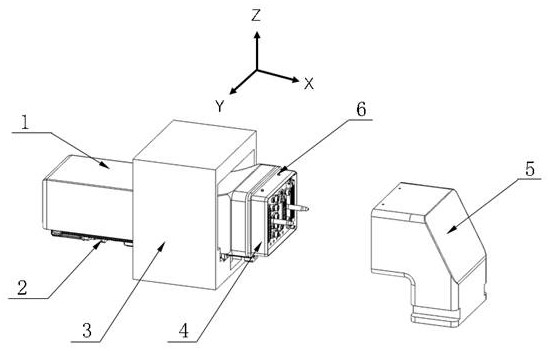

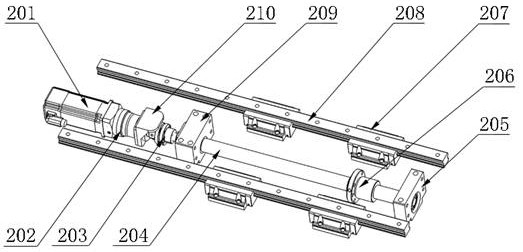

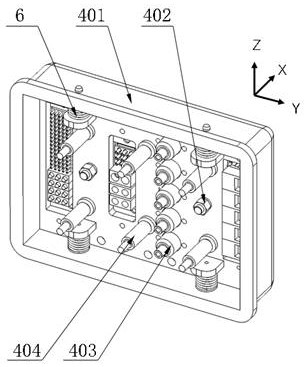

[0057] Such as Figure 1-Figure 6 As shown, this embodiment proposes an automatic plug-in device for six-degree-of-freedom adaptive pose adjustment, such as figure 1 As shown, the automatic plugging device includes a supply end base 1, a driving mechanism 2, a transfer device 3, a docking male board 4, a docking mother board 5, a locking mechanism 6, a calibration device and a Adaptive body.

[0058] The supply end base 1, the driving mechanism 2, the transfer device 3, the locking mechanism 6, the calibration device and the self-adaptive mechanism can cooperate with each other to realize the connection between the docking male board 4 and the docking mother board 5 Connectors can be connected accurately. Among them, the docking process is that the transfer device 3 transfers the docking male board 4 to the vicinity of the docking mother board 5 in the X direction, and then the calibration device makes the adaptive mechanism and the docking male board 4 return to zero positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com