Recycling method of solar backboard material

A technology of a solar back sheet and a recycling method, which is applied in the field of polymer material recycling and reuse, can solve problems such as hindering the large-scale promotion of solar cells, failing to meet the requirements of energy conservation and emission reduction, waste of economic value of materials, etc. Low-cost, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for recycling solar backboard materials, comprising the following steps:

[0026] (1) Use a crusher to break the solar backplane material into pieces;

[0027] (2) After mixing 20 parts of water, 50 parts of sodium hydroxide, 5 parts of JFC-1 and 60 parts of acetone uniformly, a separating liquid is obtained;

[0028] (3) Place the broken solar backboard material in step (1) into the separation liquid obtained in step (2), and after stirring at 30° C. for 0.1 hour, the separation liquid makes the outer protective layer of the solar backboard material, The interlayer and lamination bonding layer are separated, so that the core structure of the solar backsheet material is completely separated and recycled separately.

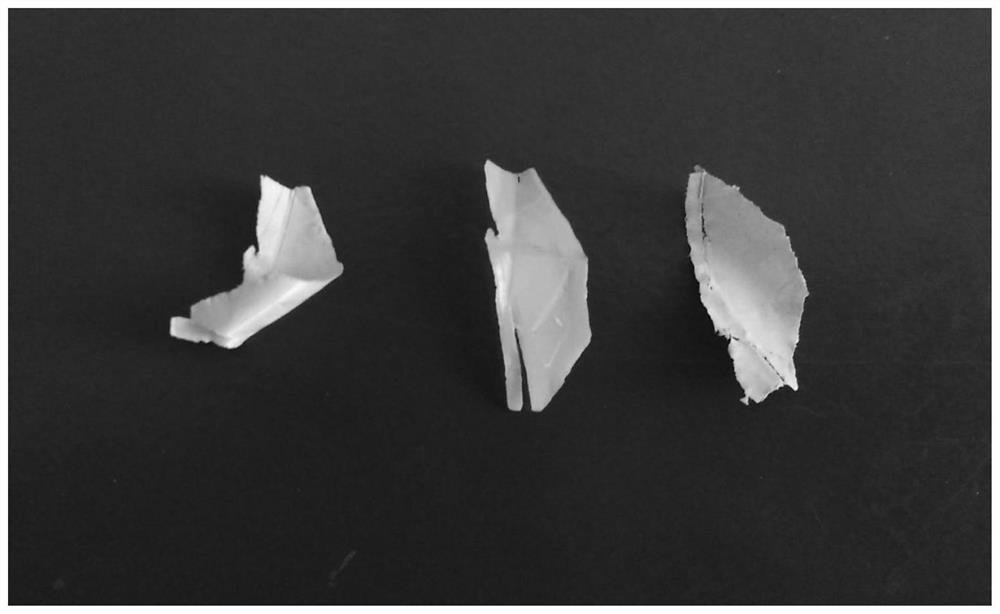

[0029] A schematic diagram of one of the fragments of the solar backsheet material after separation is shown in figure 1 As shown, the materials from left to right in the figure are PVDF as the outer protective layer, PET as the middle layer and ...

Embodiment 2

[0031] A method for recycling solar backboard materials, comprising the following steps:

[0032] (1) Use a crusher to break the solar backplane material into pieces;

[0033] (2) After mixing 500 parts of water, 1 part of potassium hydroxide, 0.1 part of JFC-E and 10 parts of ethanol evenly, a separation liquid is obtained;

[0034] (3) Place the broken solar backboard material in step (1) into the separation liquid obtained in step (2), and after stirring for 72 hours at 100° C., the separation liquid makes the outer protective layer of the solar backboard material, The interlayer and lamination bonding layer are separated, so that the core structure of the solar backsheet material is completely separated and recycled separately.

Embodiment 3

[0036] A method for recycling solar backboard materials, comprising the following steps:

[0037] (1) Use a crusher to break the solar backplane material into pieces;

[0038] (2) After mixing 100 parts of water, 20 parts of calcium hydroxide, 1 part of JFC-2 and 20 parts of methanol evenly, a separation liquid is obtained;

[0039] (3) Place the broken solar backboard material in step (1) into the separation liquid obtained in step (2), and after stirring for 10 hours at 50° C., the separation liquid makes the outer protective layer of the solar backboard material, The interlayer and lamination bonding layer are separated, so that the core structure of the solar backsheet material is completely separated and recycled separately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com