Pulsator washing machine

A pulsator washing machine, washing machine technology, applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of inconvenient control of the amount of additives, too much or too little additives, and inconvenient cleaning of storage boxes, etc. Achieve the effect of being suitable for promotion and use, improving the convenience of delivery, and efficient and quick delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

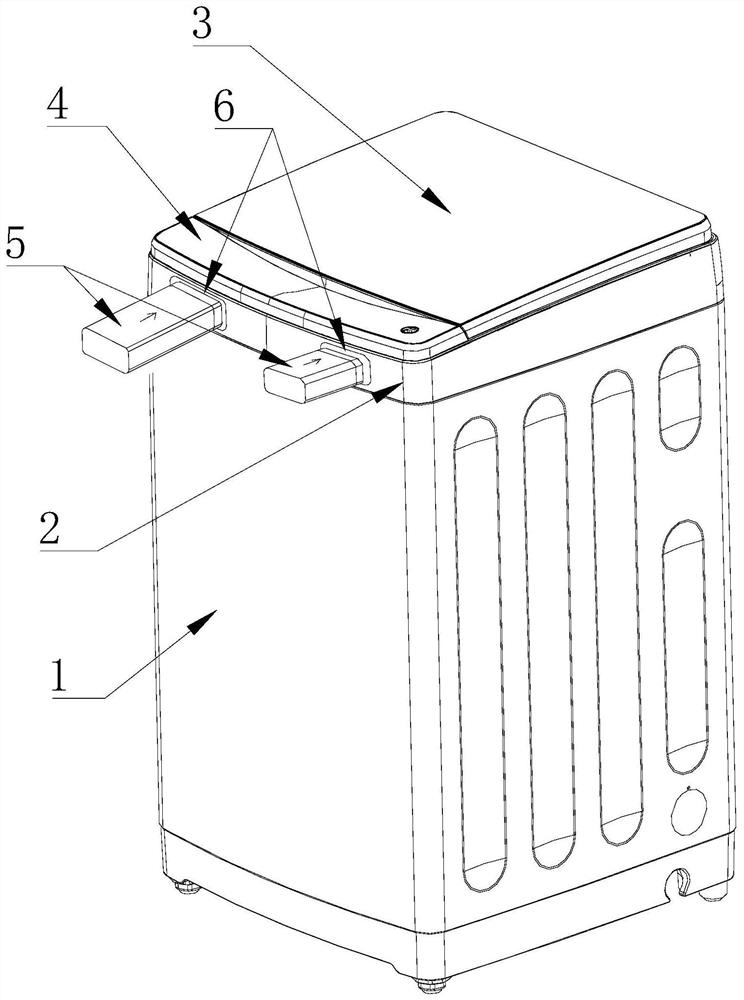

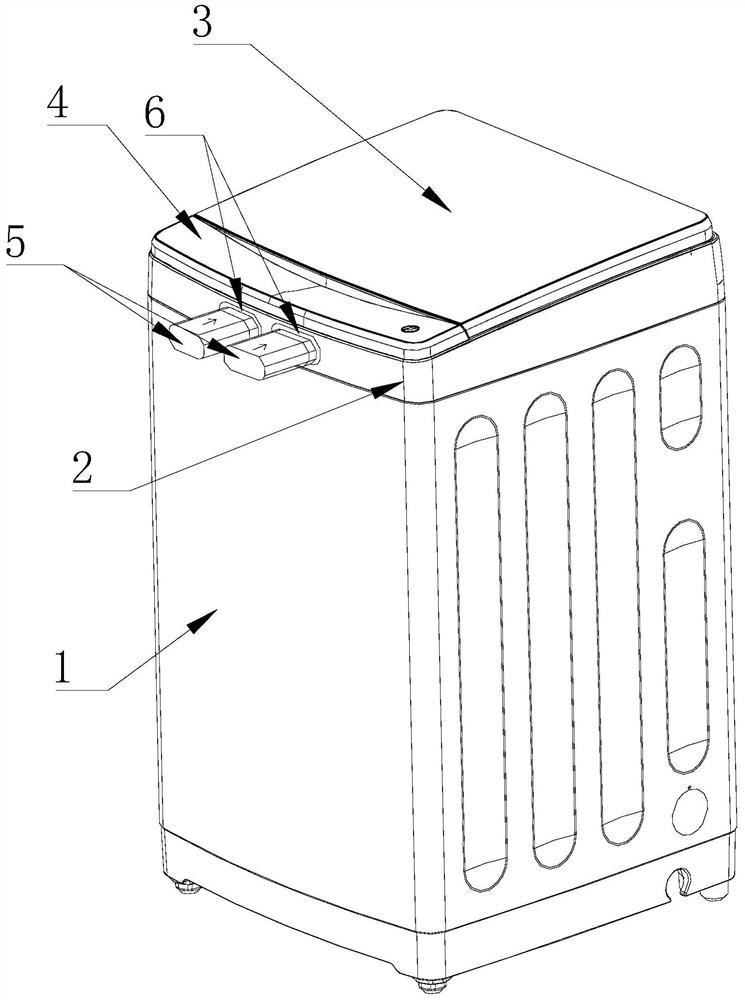

[0040] like Figure 1 to Figure 4 In this embodiment, a pulsator washing machine is introduced, which includes a box body 1, a control panel seat 2 is installed on the top of the box body 1, the control panel seat 2 is in a ring structure, and the inner periphery of the ring structure is a clothes insertion port 8, and the ring control panel The interior of the seat 2 is hollow, and the power supply components, control valves, pipelines, etc. of the hollow part are installed.

[0041] In this embodiment, the insertion groove 6 is arranged inside the control panel base 2, and the opening of the insertion groove 6 is located on the outer wall of the control panel base 2 and opened toward the outside of the washing machine, so that the additive storage box 5 can be inserted and inserted smoothly from the opening. In the groove 6, the purpose of smoothly plugging and unplugging the additive containing box 5 into the control panel base 2 is realized.

[0042] Preferably, in order ...

Embodiment 2

[0048] The difference between this embodiment and the first embodiment above is:

[0049] like Figure 5 to Figure 10 As shown, in this embodiment, the opening of the insertion slot 6 can also be arranged on the upper end surface of the control panel base 2, and the insertion slot 6 is arranged vertically downward or obliquely downward in the control panel base 2, and the additive contains The box 5 can be pulled up and down and inserted into the insertion slot 6. The lower end of the additive storage box 5 is provided with a connecting structure corresponding to the lower end of the insertion slot 6 for additive injection. The upper end of the insertion slot 6 is open and the lower end is closed, and the upper end opening of the insertion slot 6 is located on the upper end surface of the control panel base 2, so that the opening of the insertion slot 6 is located on the upper end surface of the control panel base 2, which is convenient for users. Take and place the additive ...

Embodiment 3

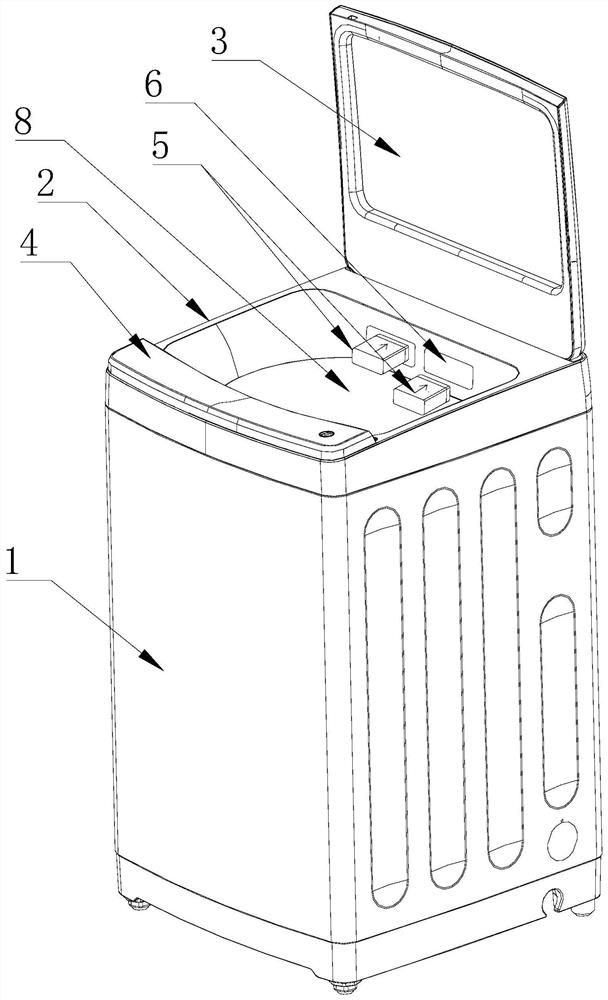

[0055] like Figure 11 As shown, a pulsator washing machine is introduced in this embodiment, which includes a box body 1, a control panel seat 2 is installed on the top of the box body 1, and the control panel seat 2 is in a ring structure, and the inner periphery of the ring structure is a clothes insertion port 8, The upper end surface of the control panel base 2 is equipped with a door cover 3 that can open and close the clothing input port 8; connected to realize the opening and closing operation of the clothes insertion port 8.

[0056] In this embodiment, the door cover 3 is connected to the control panel seat 2 via a hinge, and the door cover 3 is a plate-shaped structure that is correspondingly fastened above the control panel seat 2 and covers and closes the clothes delivery port 8. The rear side of the door cover 3 The hinge structure is connected to the rear of the control panel base 2, so that the door cover 3 can be turned upside down to open, and downturned to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com