Rapid warning and dredging device for tunnel drainage

A tunnel drainage and fast technology, which is applied in the direction of water supply equipment, drainage, mining equipment, etc., can solve the problems of inconvenience, easy blockage and dredging of tunnel drainage pipes, and achieve the effect of solving easy blockage, compact overall structure design, and convenient dredging operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

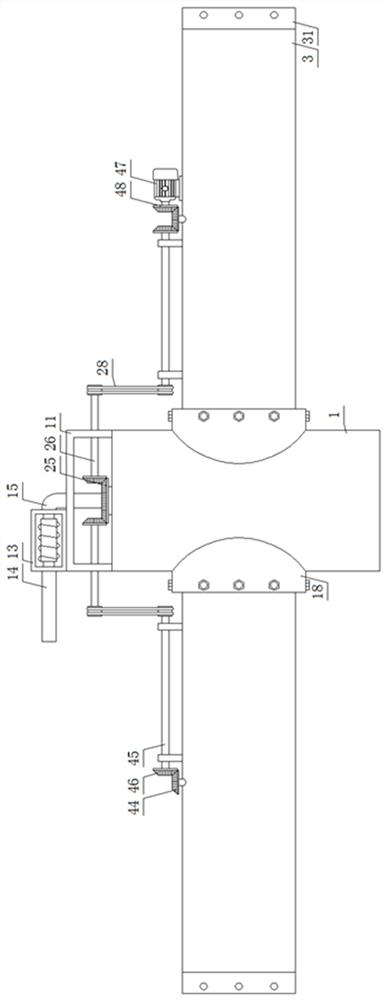

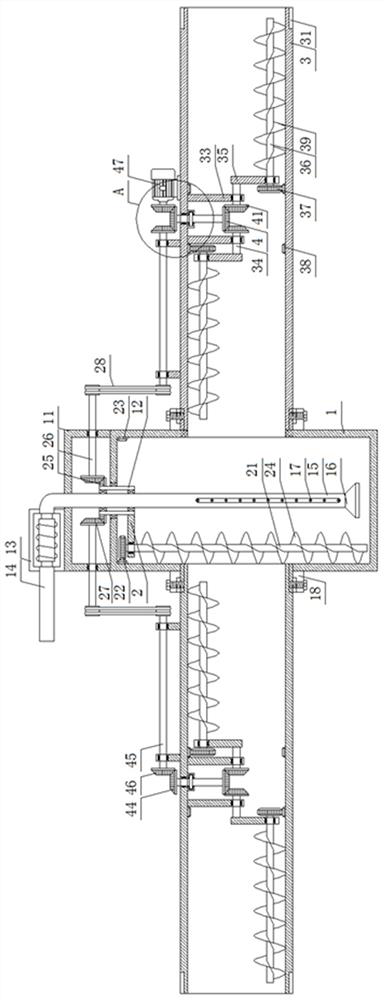

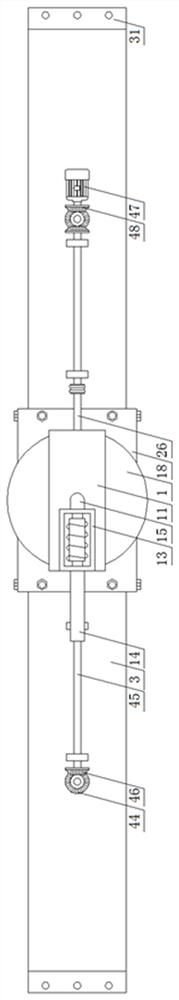

[0029] Embodiment 1: In order to achieve the purpose of facilitating the dredging of tunnel drainage pipes, this embodiment provides a quick warning and dredging device for tunnel drainage, see Figure 1-5 Specifically, it includes a silt discharge cylinder 1 and a drainage pipe 3. The silt discharge cylinder 1 is a hollow cylinder placed vertically. Both sides of the bottom surface of the U-shaped horizontal plate 11 are affixed to both sides of the top surface of the silt discharge cylinder 1, and the middle part of the top wall of the silt discharge cylinder 1 is provided with a bearing ring that penetrates and is fixed. Connected hollow shaft 12, the bottom side of the hollow shaft 12 is provided with a first connecting plate 2, the outer end of the first connecting plate 2 is provided with a first planetary screw mechanism, and the top side of the U-shaped horizontal plate 11 is provided with pumping components;

[0030] Both sides of the central part of the silt dischar...

Embodiment 2

[0040] Embodiment two: in embodiment one, there is also the problem that the inner wall of the silt discharge cylinder is easy to absorb silt and impurities. Therefore, on the basis of embodiment one, this embodiment also includes:

[0041] In the specific implementation process, such as figure 2 and Figure 5 As shown, the first planetary screw mechanism includes a first planetary shaft 21, a first screw blade 24, a first bearing is provided on the outer end of the first connecting plate 2, and a first vertically penetrating first bearing is inserted inside the first bearing. The planetary shaft 21 is located above the first connecting plate 2. The top end of the first planetary shaft 21 is sleeved with a concentric fixed first planetary gear 22. It is located at the concentric position of the first planetary gear 22. The wall is provided with a concentrically fixed first gear ring 23, and the first planetary gear 22 is meshed with the first gear ring 23, and is located bel...

Embodiment 3

[0042] Embodiment 3: In Embodiment 1, there are also problems of inconvenient silt discharge after the installation of some drainage pipes. Therefore, on the basis of Embodiment 1, this embodiment also includes:

[0043] In the specific implementation process, such as Figure 6 As shown, when several drainage pipes 3 are installed, the joints of two adjacent drainage pipes 3 are all connected to the silt discharge cylinder 1, and the rest of the structure is the same as that in Embodiment 1; A pair of second horizontal shafts 45 are arranged on both sides of the top surface of the corresponding drainage pipe 3 between the cylinders 1, and the opposite ends of the pair of second horizontal shafts 45 are meshed with the sixth bevel gear 44 through the fifth bevel gear 46. , the opposite ends of a pair of second horizontal shafts 45 are connected to the corresponding first horizontal shafts 26 through the driving belt 28. Through the above-mentioned settings, only one servo motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com