Vibration isolator, adjusting method of vibration isolator and spring replacing method of vibration isolator

An adjustment method and a technology of vibration isolators, which are applied in the manufacture of tools, building components, shockproof, etc., can solve the problems of long construction time, heavy steel plate, high load and installation space requirements, and achieve the effect of reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

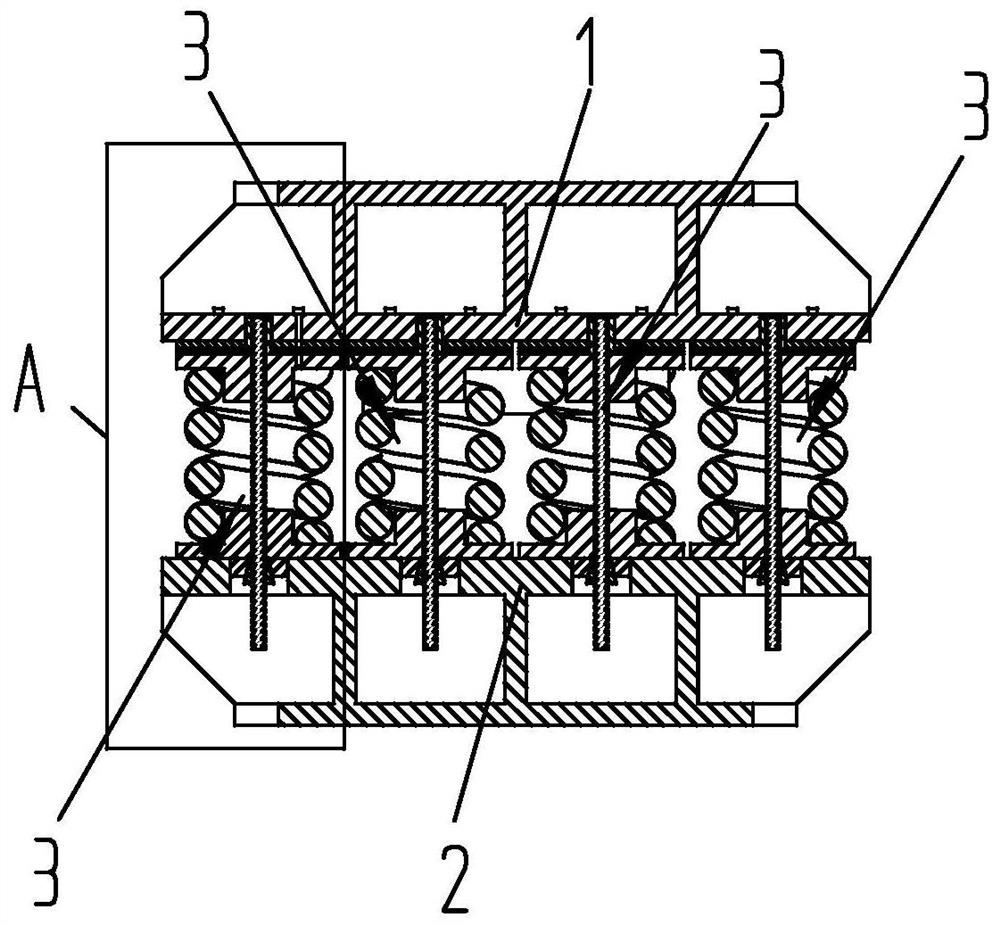

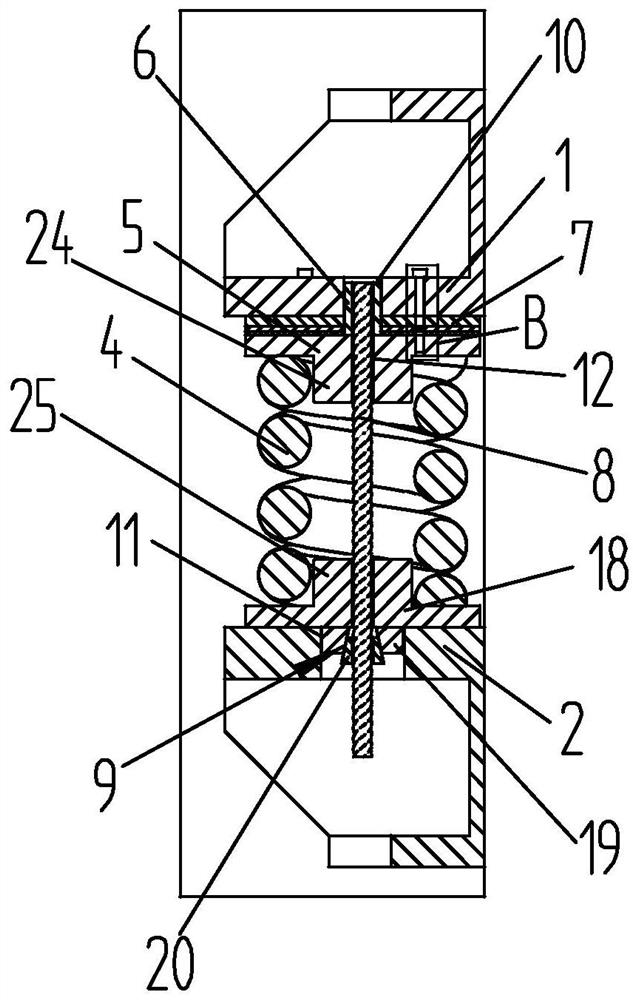

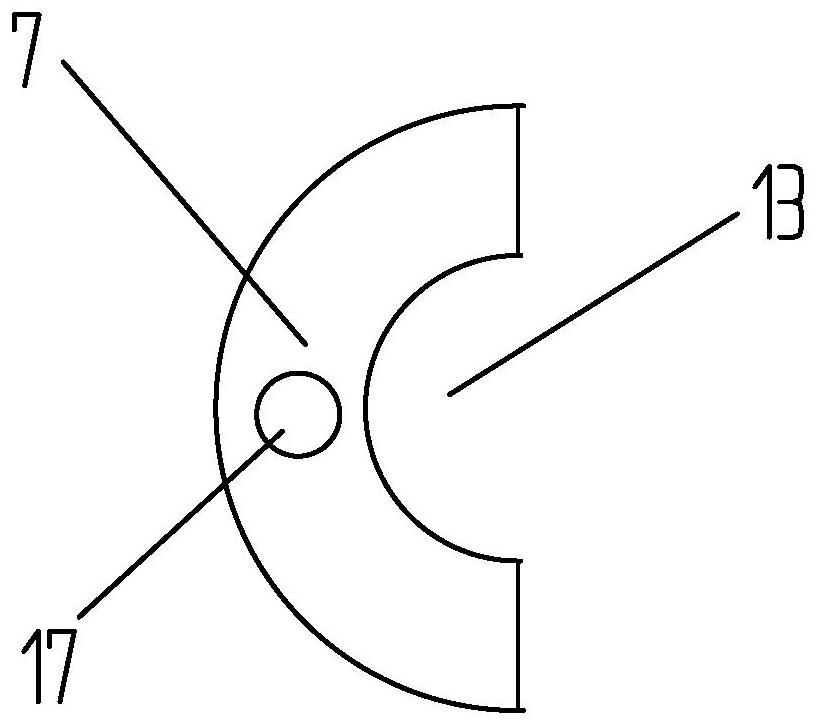

[0065] like figure 1 , 2 As shown, a vibration isolator includes: an upper cover plate 1, a lower seat plate 2 and at least two buffer units 3. The buffer unit 3 includes a compression spring 4, a spring cover plate 5, a pressing part 6, and an adjustment pad 7 , the pulling cable 8 and the locking mechanism 9 . The upper cover plate 1 and the lower seat plate 2 are spaced apart. One end of the compression spring 4 is connected to the lower seat plate 2 , and the other end is abutted on the upper cover plate 1 through the spring cover plate 5 and the adjusting pad 7 in sequence. The upper cover plate 1 is provided with a first through hole 10 , the lower seat plate 2 is provided with a second through hole 11 , and the spring cover plate 5 is provided with a third through hole 12 . The axis of the second through hole 11 and the axis of the third through hole 12 are both coincident with the axis of the compression spring 4 . The pressing member 6 is arranged in the first thro...

Embodiment 2

[0074] like Figure 7 As shown, a method for adjusting a vibration isolator, for adjusting the vibration isolator in the first embodiment above, includes the steps:

[0075] S200, applying a pulling force to the pulling cable, so that the extruding member presses the spring cover plate to compress the compression spring, so as to increase the distance between the spring cover plate and the upper cover plate;

[0076] S300, adjusting the thickness of the adjusting pad located between the spring cover and the upper cover;

[0077] S400 , releasing the pulling force on the pulling cable, so that the spring cover plate is abutted on the upper cover plate through the adjusting pad under the elastic force of the compression spring.

[0078] With such a technical solution, only the compression spring of one buffer unit needs to be compressed during adjustment, so it is only necessary to apply a small pulling force to the pulling cable, and the weight of the adjustment pad is also re...

Embodiment 3

[0089] like Figure 8 As shown, a spring replacement method for a vibration isolator is used to replace the compression spring in the vibration isolator in the first embodiment, including the steps:

[0090] S200', applying a pulling force to the pulling cable, so that the extrusion part presses the spring cover to compress the compression spring, so that the spring cover cover moves toward a position away from the upper cover;

[0091] S300', fix the pulling cable on the lower seat plate through the locking mechanism, so as to keep the spring cover at a position away from the upper cover;

[0092] S400', separate the compression spring from the lower seat plate, and then take out the compression spring from the vibration isolator;

[0093] S500', set the new compression spring on the pulling cable, and compress the new spring through the spring cover;

[0094] S600', connect the end of the new spring away from the spring cover to the lower seat plate;

[0095] S700', relea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com