Back ridge connecting device for reinforcing fair-faced concrete formwork

A fair-faced concrete and formwork reinforcement technology, which is applied in the connection of formwork/formwork/work frame, formwork/formwork/work frame, and on-site preparation of building components. The time to select the connector, the troublesome operation of the connector, etc., can ensure the effect of multi-angle rotation, reduce the repair cost and save time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

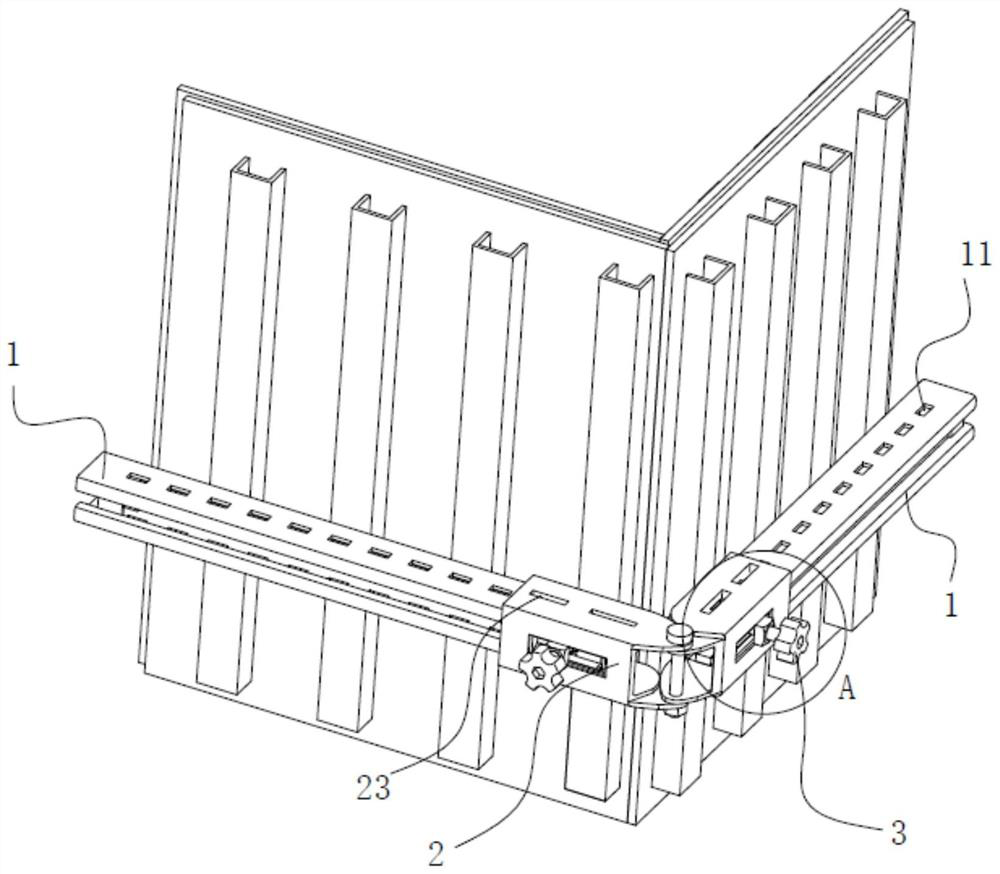

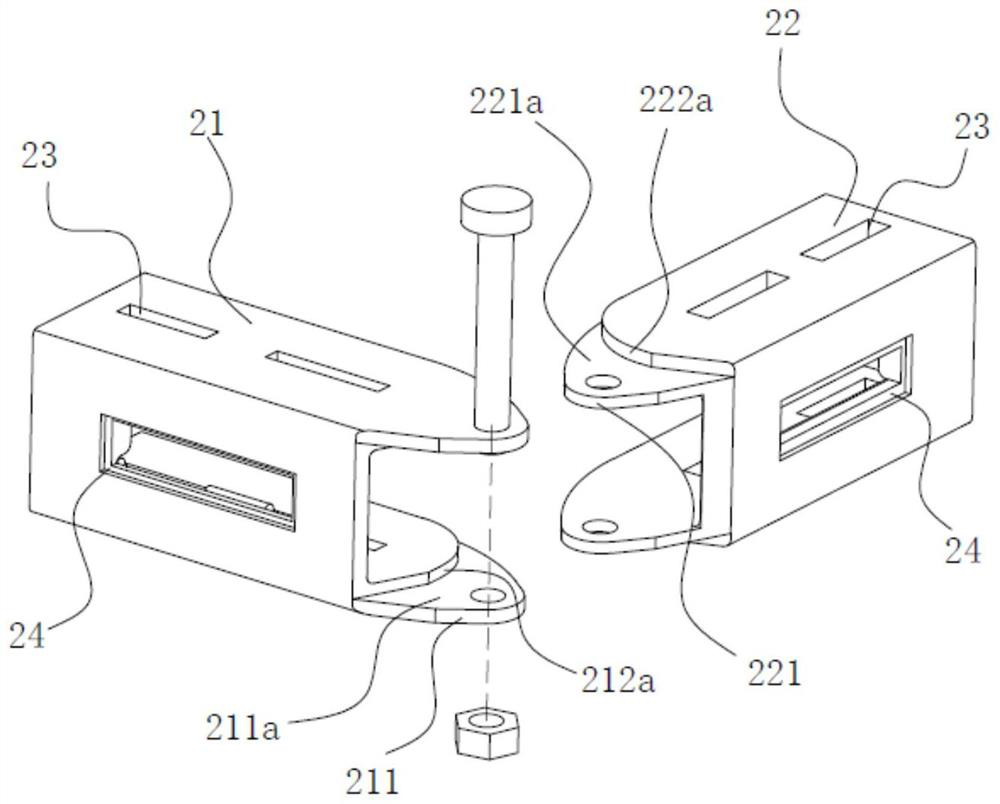

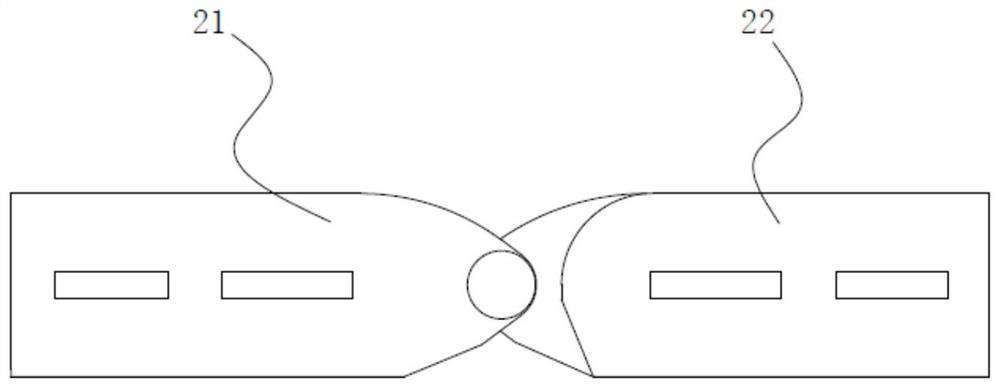

[0039] Such as Figure 1 to Figure 7 The shown concrete formwork reinforcement back flute connecting device includes two main back flutes 1 located on the same horizontal plane, wherein it also includes a connecting piece 2, and the connecting piece 2 includes a first fixing piece 21 and is rotatably connected with the first fixing piece 21. The second fixing piece 22, the first fixing piece 21 and the second fixing piece 22 cover the sides and the upper and lower surfaces of the two main back corrugated 1, and the first fixing piece 21 and the second fixing piece 22 are provided with the main back The several first connecting holes 11 on the flute 1 correspond to several second connecting holes 23 . It should be noted that the first connecting hole 11 is provided on the side and upper and lower surfaces of the first fixing member 21 and the second fixing member 22, and the main back corrugated 1 is composed of two facing C-shaped steel materials and connecting plates, and the...

Embodiment 2

[0049] In the second embodiment of the present invention, another structure of the first connection part 211 and the second connection part 221 is shown, and the structure and connection relationship of the remaining components are the same as those of the first embodiment, and will not be repeated here.

[0050] Specifically, such as Figure 8 to Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that the ends of the first connecting part 211 and the second connecting part 221 are provided with a main hinge part 211b and a secondary hinge part 221b, and the main hinge part 211b and the secondary hinge part 221b are arranged opposite to each other. There are several slots and protrusions, and fixing bolts are arranged in the overlapping area perpendicular to the slots and protrusions, and the main hinge part 211b and the secondary hinge part 221b are rotatably connected by fixing bolts. The main hinged part 211b and the secondary hinged part 221b ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com