Civil aircraft cabin door automatic drilling and riveting path planning method based on improved ant colony algorithm

A technology of automatic drilling and riveting and ant colony algorithm, which is applied in the direction of instruments, digital control, control/regulation systems, etc., can solve the problems of low efficiency of experience and low efficiency of automatic drilling and riveting, achieve short paths, improve the efficiency of automatic drilling and riveting, The effect of fast convergence speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

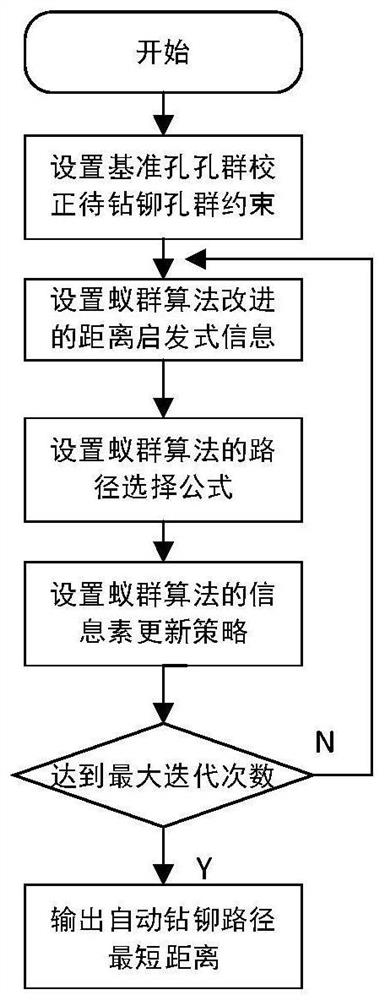

[0094] The embodiment procedure of the present invention is described in detail below ( Figure 6 ), this embodiment routine is implemented under the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following embodiment routine. The implementation routine can be mainly divided into the following steps:

[0095] Step 1: Determine the mathematical model and constraints for path planning of the door to be drilled and riveted holes.

[0096] Step 1.1: Determine the mathematical model of discrete hole group path planning

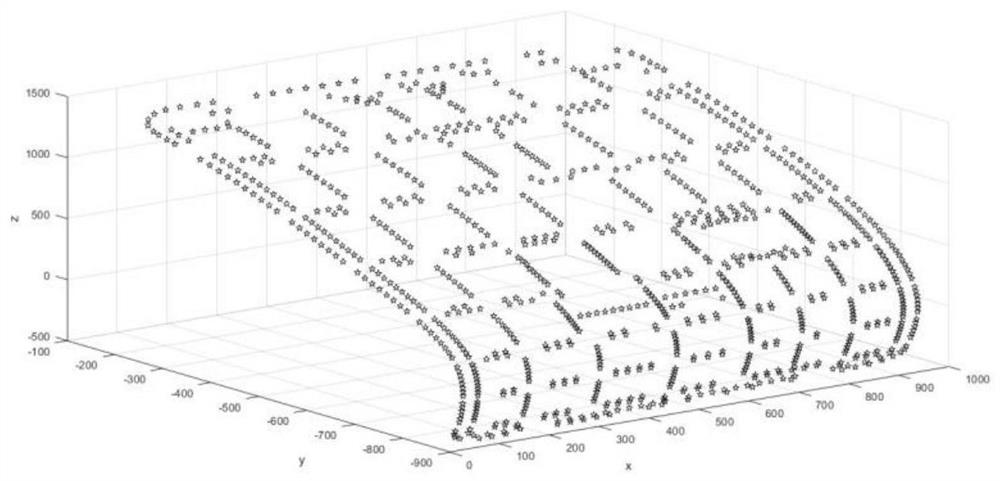

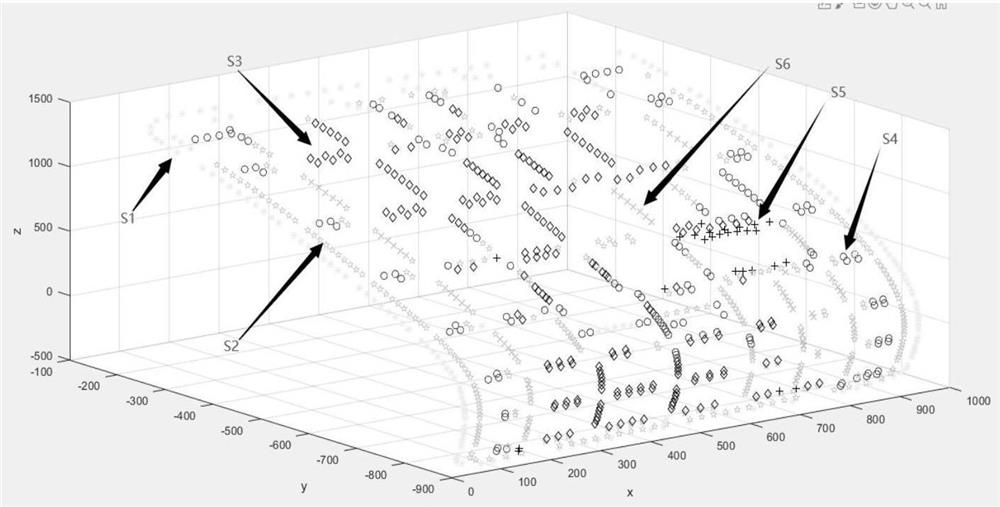

[0097] In the process of automatic drilling and riveting path planning, the distance between the adjacent holes to be drilled and riveted holes that need to be drilled on the cabin door of the civil aircraft is close, such as figure 1 As shown, the processing sequence of these holes has no strict technical r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com