Gradient vamp and knitting process thereof

A technology of shoe uppers and craftsmanship, which is applied to uppers, shoes, boot legs, etc., can solve the problems of single color matching and lack of flexibility, etc., and achieve the effect of strong air permeability, strengthened internal and external structures, and improved stability and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

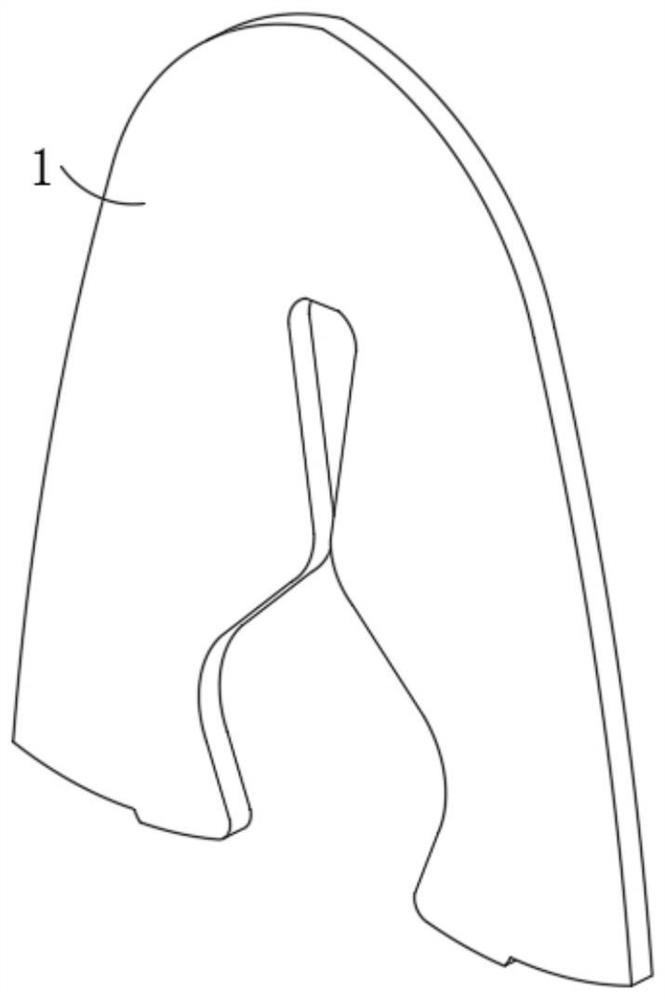

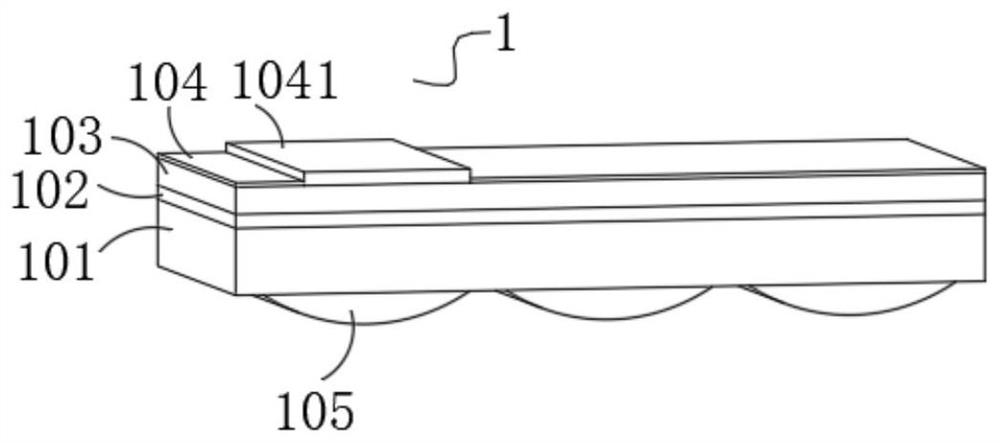

[0042] A gradient shoe upper, including a shoe panel 1 as a textile body, and the shoe panel 1 includes a substrate 101 used as a panel base and used in gradient color matching:

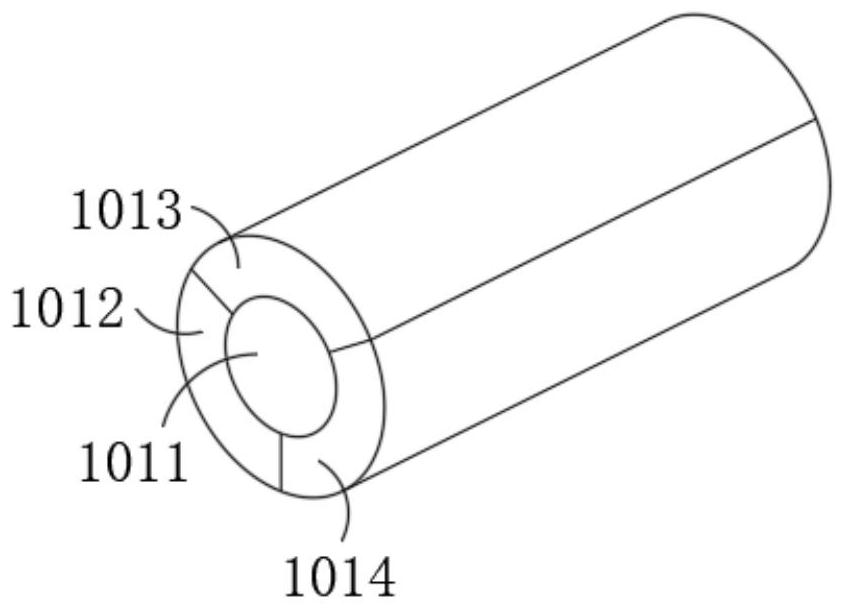

[0043] Wherein, the substrate 101 is made of textile thread weaving, and the textile thread includes a reinforcing thread 1011 as the main body of the thread stretching. On the strip body of the reinforcing thread 1011, the first primary color thread 1012 and the second primary color thread are arranged in a circular array with the center as the base point. 1013 and the third primary color line 1014, the line bodies of the first primary color line 1012, the second primary color line 1013 and the third primary color line 1014 are successively connected successively, and there is no blank space on the strip body of the reinforcing line 1011, and the first primary color line is set 1012, the line bodies of the second primary color lines 1013 and the third primary color lines 1014 are sequentially dyed ac...

Embodiment 2

[0065] On the basis of embodiment 1, further improve the use quality of vamp, strengthen structure:

[0066] A gradient shoe upper, including a shoe panel 1 as a textile body, and the shoe panel 1 includes a substrate 101 used as a panel base and used in gradient color matching:

[0067] Wherein, the substrate 101 is made of textile thread weaving, and the textile thread includes a reinforcing thread 1011 as the main body of the thread stretching. On the strip body of the reinforcing thread 1011, the first primary color thread 1012 and the second primary color thread are arranged in a circular array with the center as the base point. 1013 and the third primary color line 1014, the line bodies of the first primary color line 1012, the second primary color line 1013 and the third primary color line 1014 are successively connected successively, and there is no blank space on the strip body of the reinforcing line 1011, and the first primary color line is set 1012, the line bodies...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com