Outer wall crushing and recycling device for constructional engineering

A technology of construction engineering and recovery equipment, which is applied in the direction of using liquid separation agent, solid waste removal, and separation of dispersed particles. It can solve the problems of affecting air quality, cumbersome operation, and dust outflow, so as to improve the friction effect and improve the crushing effect. , to achieve the effect of a stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

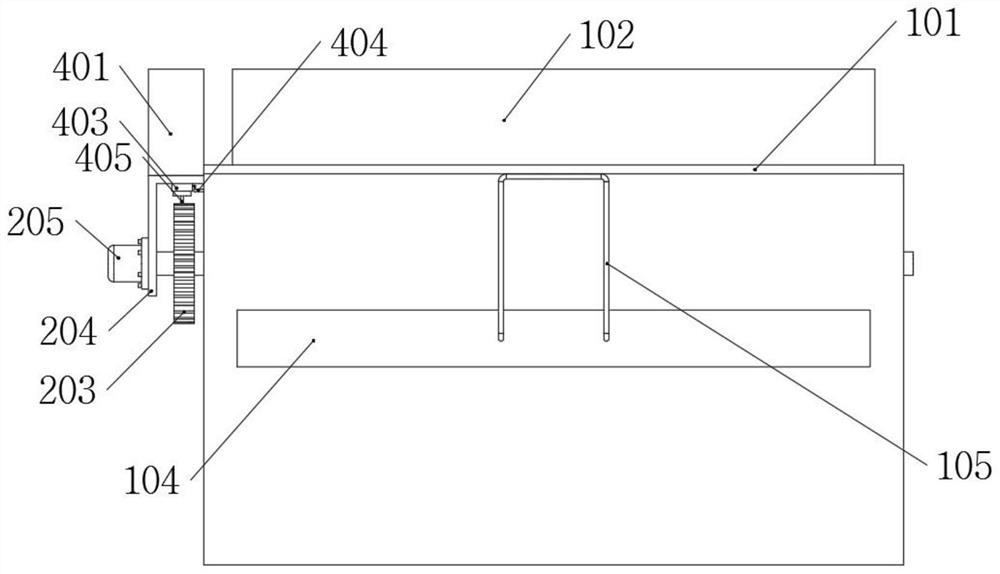

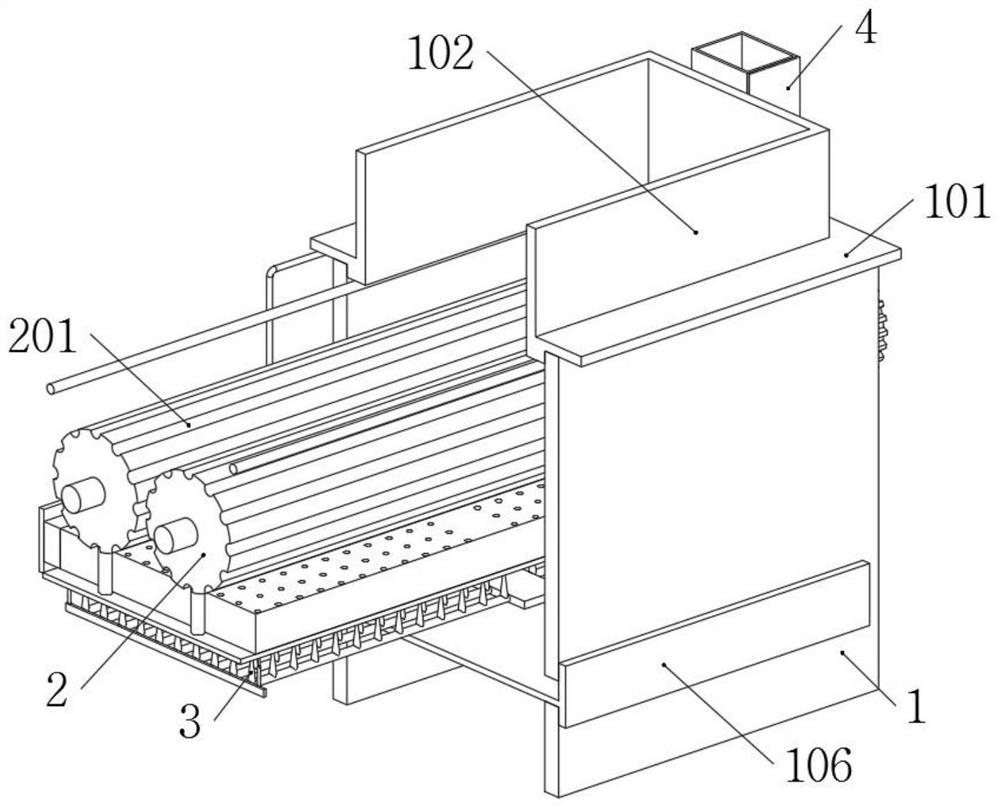

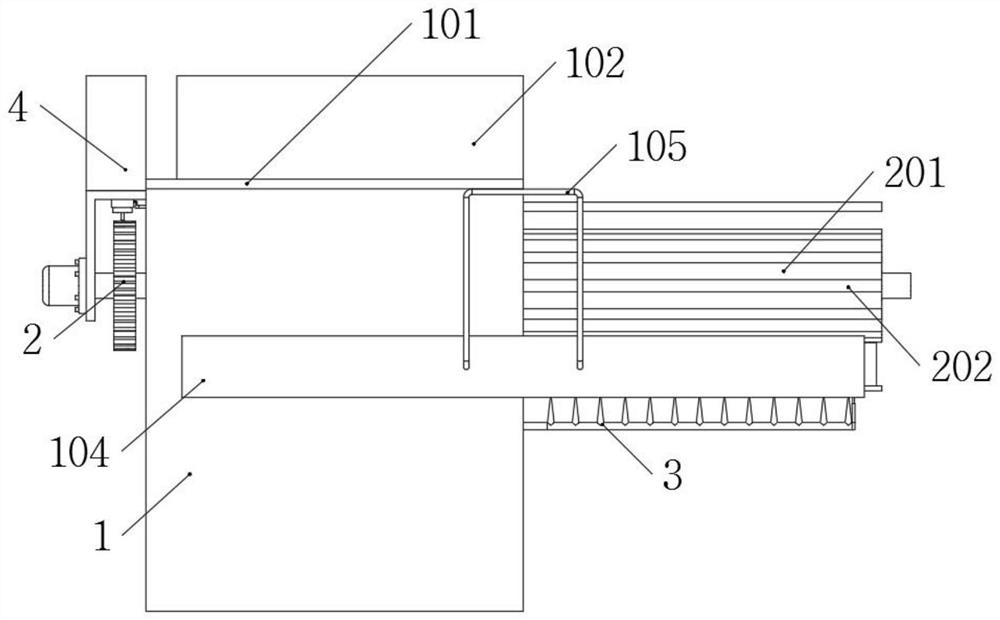

[0039] Example: Please refer to Figure 1 to Figure 8 :

[0040] The present invention proposes an exterior wall crushing and recovery device for construction engineering, including: a box body 1, a crushing part 2, an auxiliary part 3 and a dust reduction part 4;

[0041] The box body 1 is placed on the ground, and the box body 1 is plugged with a collection box 106;

[0042] The crushing part 2 is composed of a crushing roller 201, a groove 202, a gear 203, a mounting seat 204 and a driving motor 205, and there are two crushing rollers 201, and the two crushing rollers 201 are rotatably connected to the box body 1;

[0043] The auxiliary part 3 is composed of a mounting frame 301, a protrusion 302, an elastic telescopic rod 303, an auxiliary plate 304, a through hole 305 and a force rod A306, and the mounting frame 301 is fixedly connected to the box body 1 by bolts;

[0044] The dust reduction unit 4 is composed of a water storage box 401 , a fixed plate 402 , a piston bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com