Pretreatment device for particle plate before cutting

A pretreatment device and particle board technology, applied in the direction of grinding drive device, grinding/polishing safety device, manufacturing tools, etc., can solve the problem of cutting knife damage, injury to operators, nails or hard sundries squeezed and splashed, etc. problems, to achieve the effect of increasing the nail removal area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

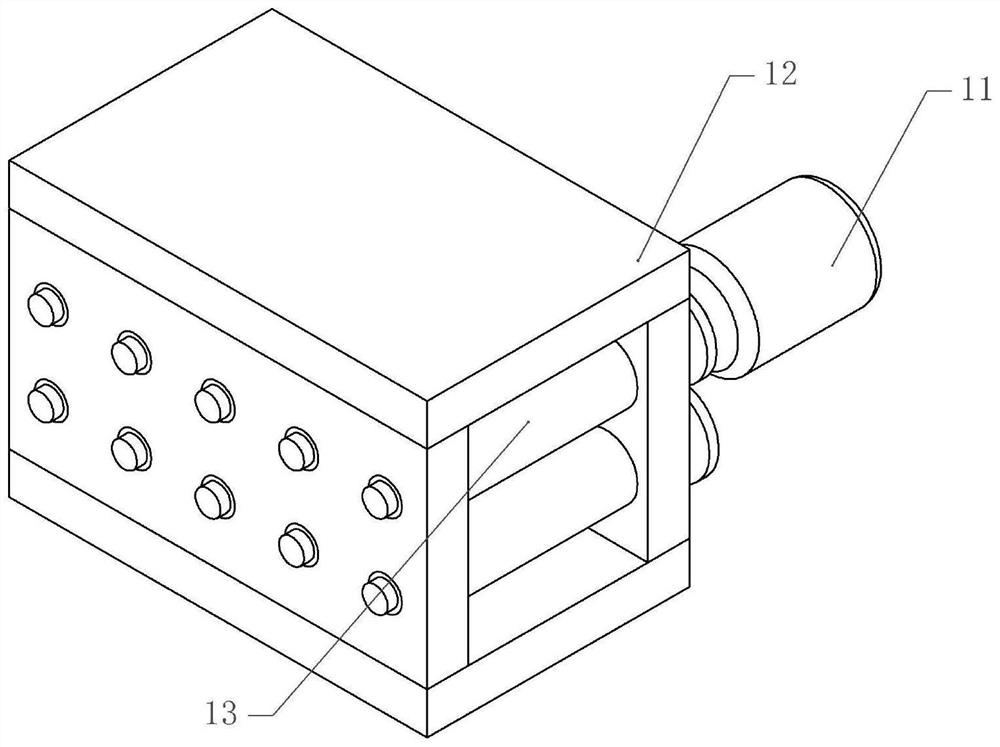

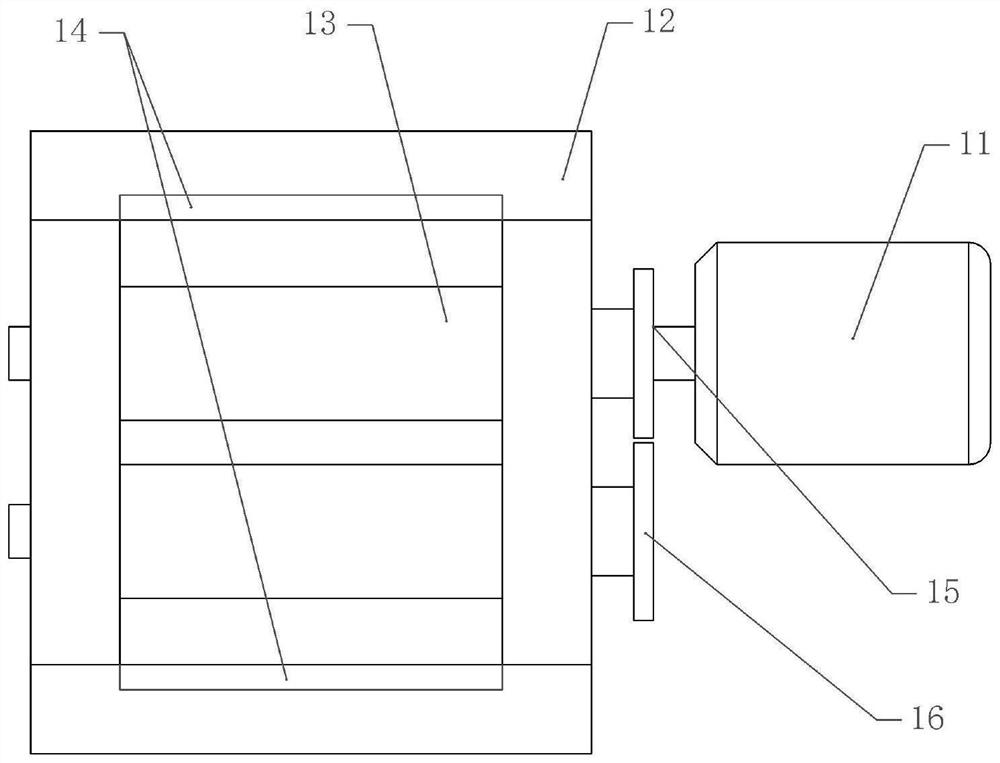

[0037] Basic as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 As shown, a particle board pre-treatment device before cutting includes a frame 12, the upper and lower parts of the frame 12 are provided with several processing components, and several processing components are arranged along the length direction of the frame 12.

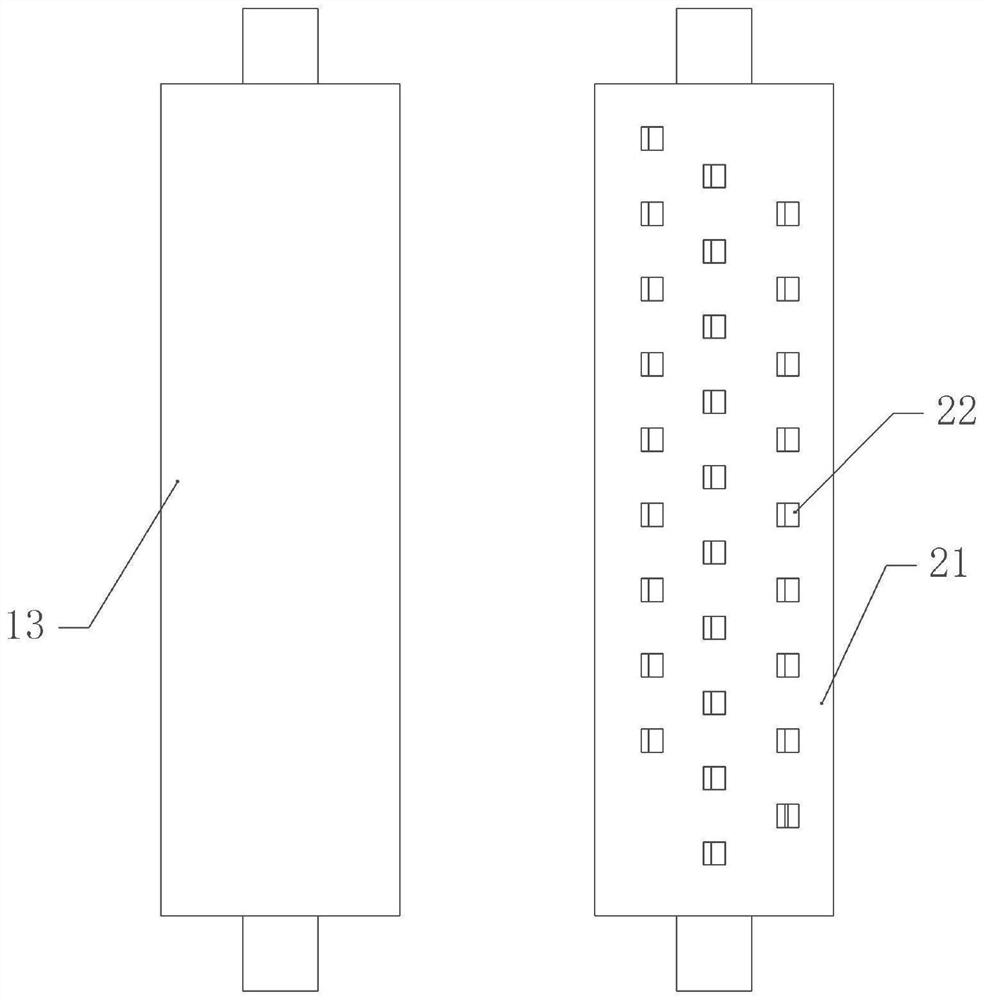

[0038] In this embodiment, the processing assembly includes a grinding roller 13 that is rotatably connected to the frame 12 and a processing roller 21 that is rotatably connected to the frame 12. The grinding roller 13 and the processing roller 21 are horizontally arranged side by side, and the outer surface of the grinding roller 13 is fixedly connected with The elastic layer, the elastic layer is a plastic plate, the elastic layer is provided with a nylon surface, the processing roller 21 is provided with a number of L-shaped first denailers 22, and several first denailers 22 are arranged in a staggered manner on...

Embodiment 2

[0046] The difference between the second embodiment and the first embodiment is that the attached Figure 5 As shown, both sides of the frame 12 are fixedly connected with some power parts by bolts, the power parts are cylinders 31, and the output shaft of the cylinder 31 is provided with an L-shaped second nail remover 32. In this embodiment, the second The horizontal section of the nail remover 32 is fixedly connected to the output shaft of the cylinder 31, and the vertical section 224 of the second nail remover 32 is fixedly connected to the horizontal section by bolts, and the vertical section is provided with an arc-shaped second nail removal opening The second grinding layer is screwed on the side away from the cylinder 31 on the vertical section, and the second grinding layer is sandpaper.

[0047] The specific implementation process is as follows:

[0048] In this embodiment, the intermittent drive cylinder 31 drives the second nail remover 32 to move toward both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com