Furniture board center drilling and grinding all-in-one machine

A center drilling and integrated machine technology, which is applied in the direction of manufacturing tools, multi-purpose machinery, wood processing appliances, etc., can solve the problems of sawdust splashing, achieve the effect of preventing flying dust and facilitating recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

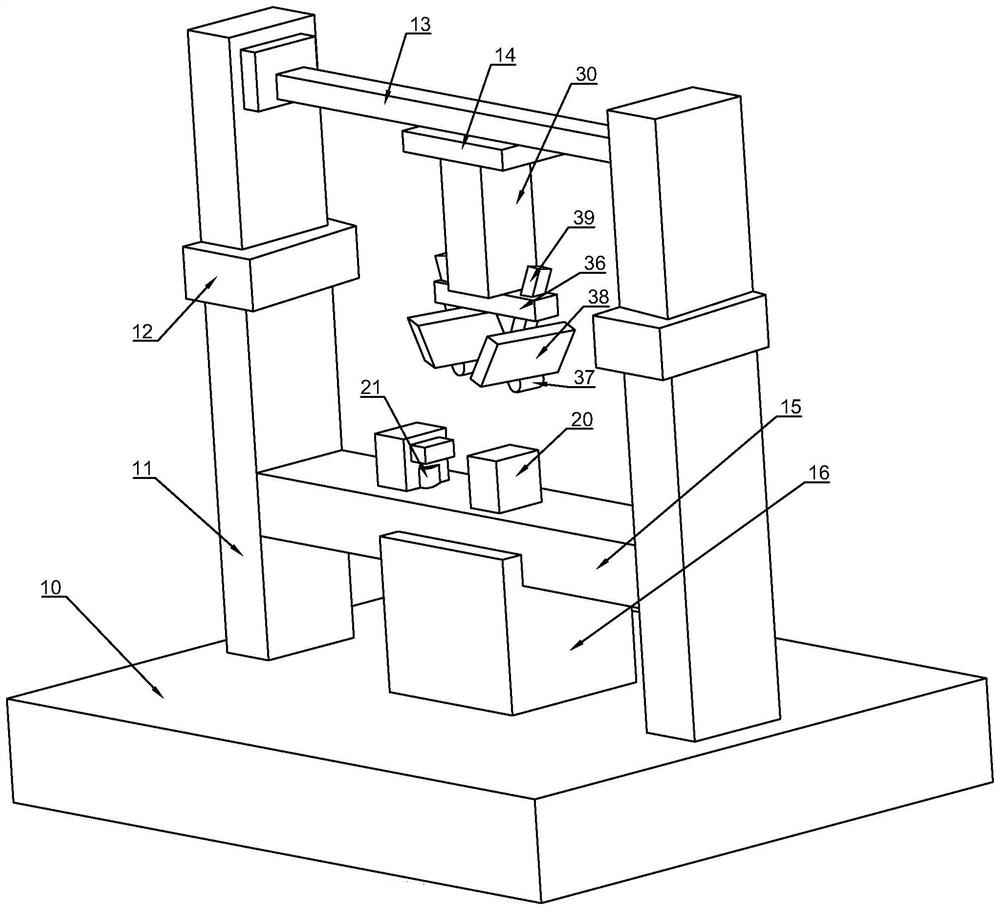

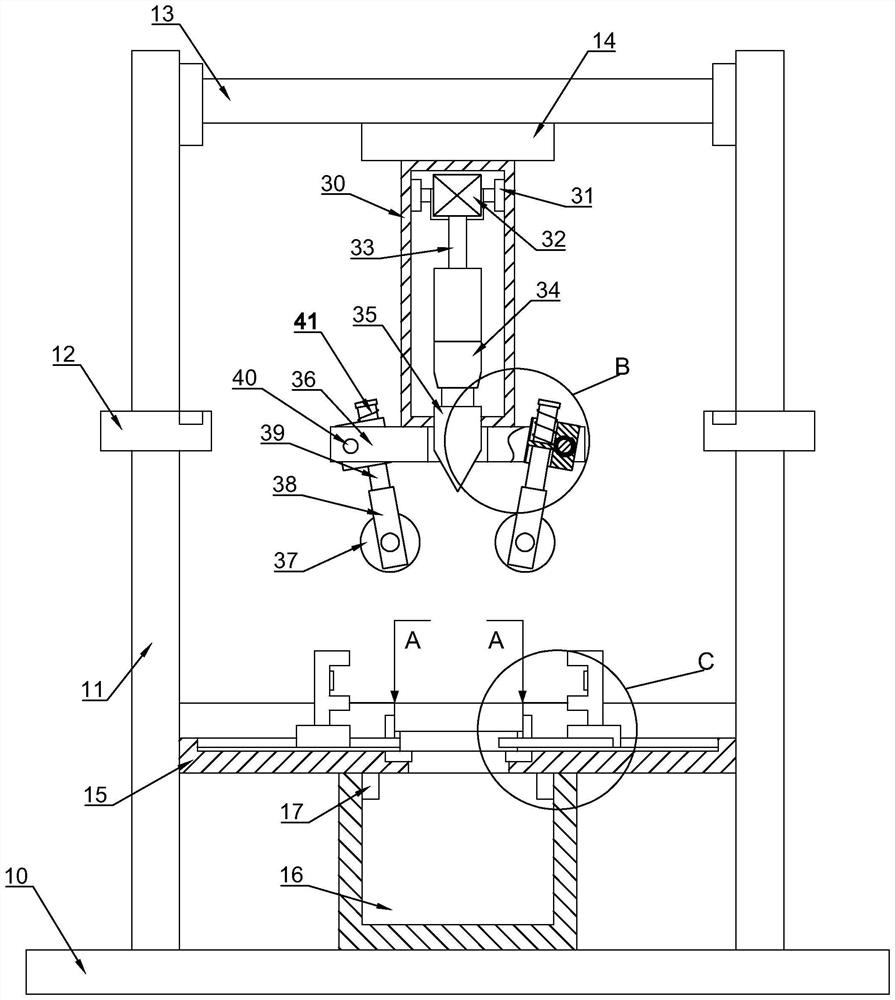

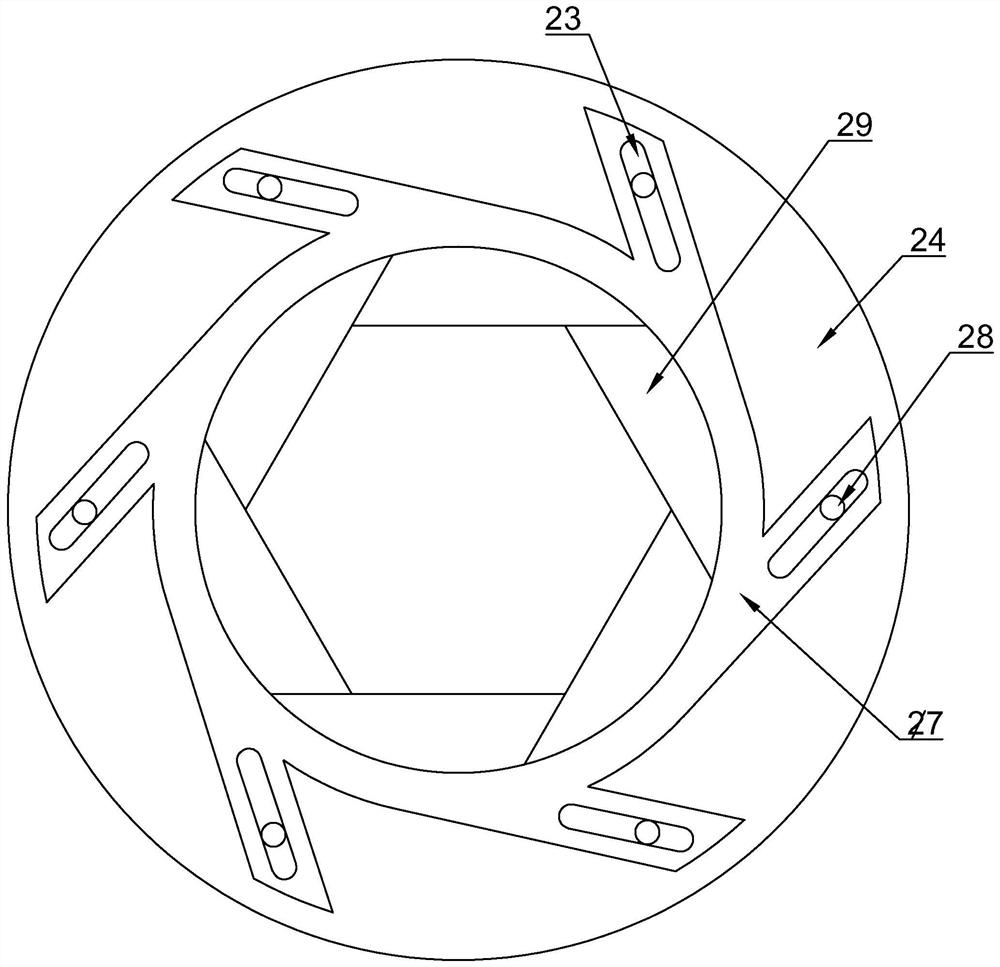

[0024] Such as figure 1 As shown, an integrated machine for drilling and polishing the center of a furniture plank, including a base 10, is characterized in that a column 11 is fixed on the upper side wall of the base 10, a fixer 12 is fixed on the column 11, and a sliding device is installed on the column 11. Sliding crossbeam 13, sliding on sliding crossbeam 13 is provided with fine-tuning platform 14, and the lower end surface of fine-tuning platform 14 is fixedly provided with drilling cavity 30, and drilling cavity 30 is provided with drilling device, and drilling device is used for carrying out the drilling of plank and polishes. , the lower end surface of the drilling cavity 30 is fixedly provided with a baffle beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com