High-tank boxing device and boxing method

A technology of canned boxes and boxes, which is applied in the field of high canned boxing devices and boxing, to achieve the effects of ensuring boxing efficiency, improving boxing efficiency, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

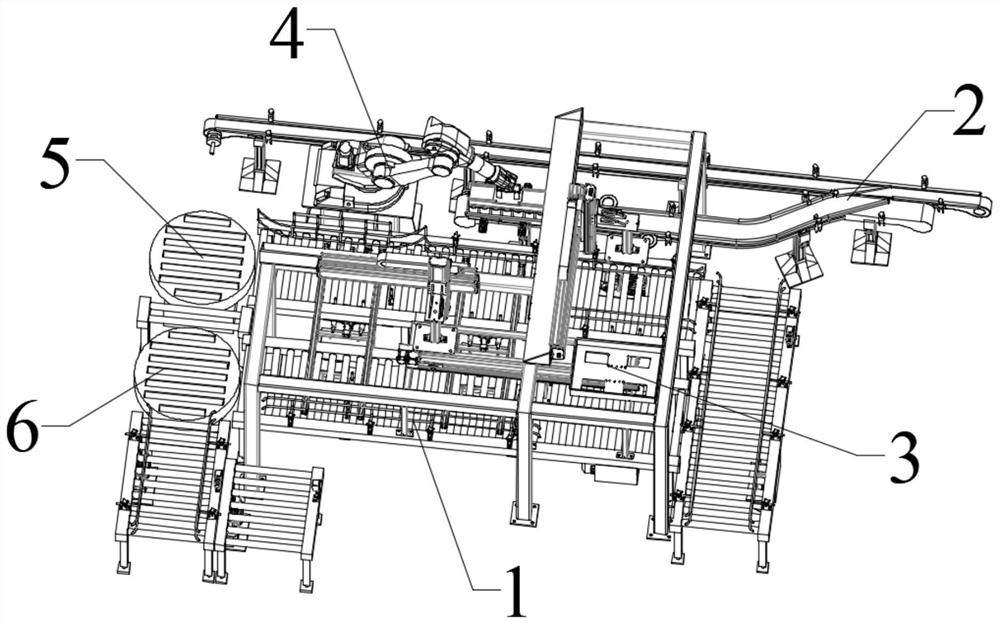

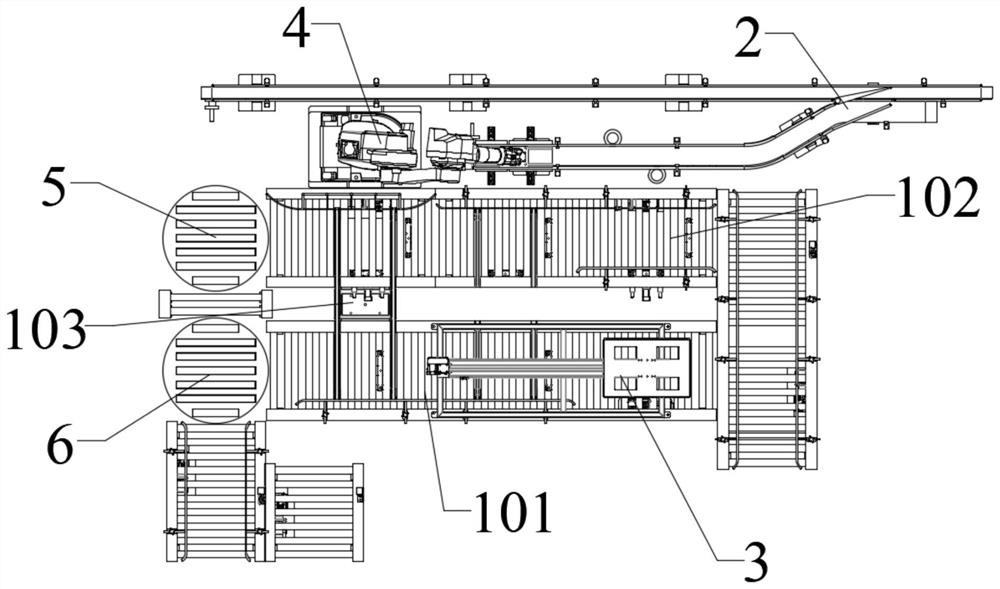

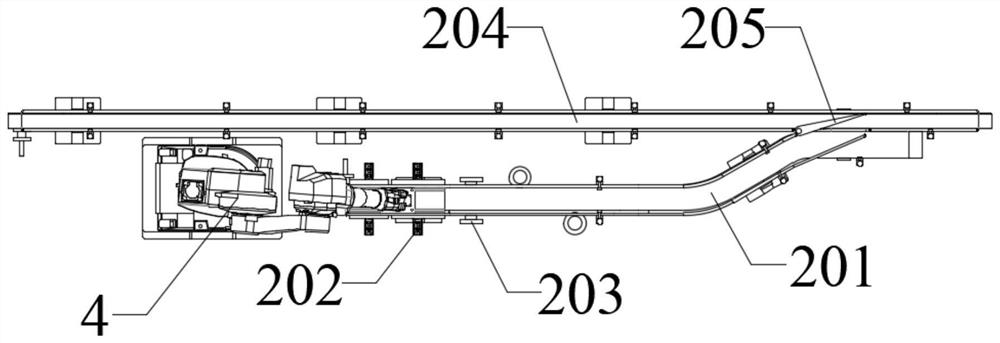

[0057] see Figure 1~4 , the tall tank packing device in the preferred embodiment of the present invention comprises a case feeding assembly 1, a tank feeding assembly 2, a cover transfer assembly 3 and a mechanical arm 4; A transportation mechanism 101 and a second transportation mechanism 102; the casing that the feeding end of the first transportation mechanism 101 enters includes a first casing and a second casing; wherein, the first casing is an empty casing, and the second casing The body is a box full of partitions; the cover plate transfer assembly 3 is arranged above the two transport mechanisms, and is used to take out the cover plates transported on the first transport mechanism 101, and the tank body on the second transport assembly Cover the cover plate after packing is completed; a first material transfer mechanism 103 is also provided between the first transport mechanism 101 and the second transport mechanism 102, and the first material transfer mechanism 103 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com