Manipulator capable of preventing wafer flower basket from falling off during clamping and having alarm function

A wafer and anti-shedding technology, applied in the field of manipulators, can solve the problems of uneven clamping arm force, wafer box falling off, loose fastenings, etc., to reduce the probability of looseness, ensure safe production, and have good synchronization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be apparent from the technical solutions of the present invention in conjunction with the present invention.

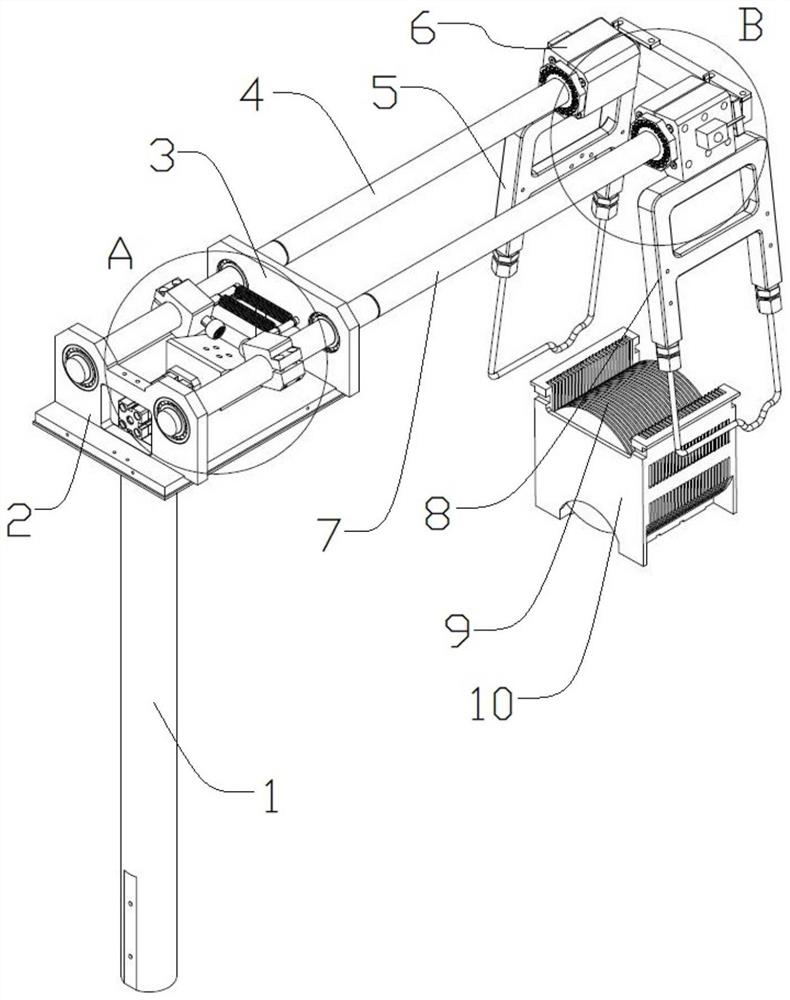

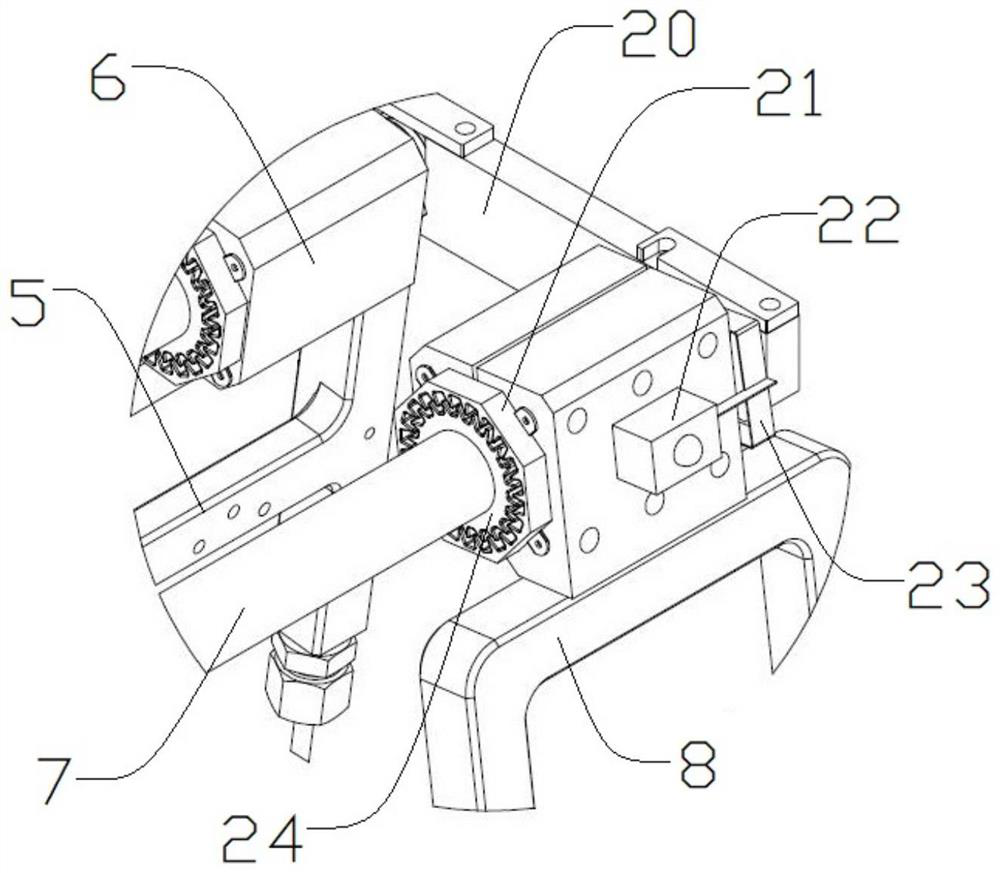

[0031] See Figure 1-6 In this embodiment, a robotic manner having a wafer flower basket clamping and alarm function comprises a rotary assembly, a rotating rod, a bearing positioning, a buffer assembly, and a camptographic wafer 9 secured to the lifting shaft 1. The clamping assembly of the basket 10, and alarm flash 22 and the touched sensing block 23 for monitoring the clamping assembly and the rotary rod, and the inductive sensing block 23, the rotating rod comprises the left side of the rotary rod 4 and the right side of the rotary rod 7.

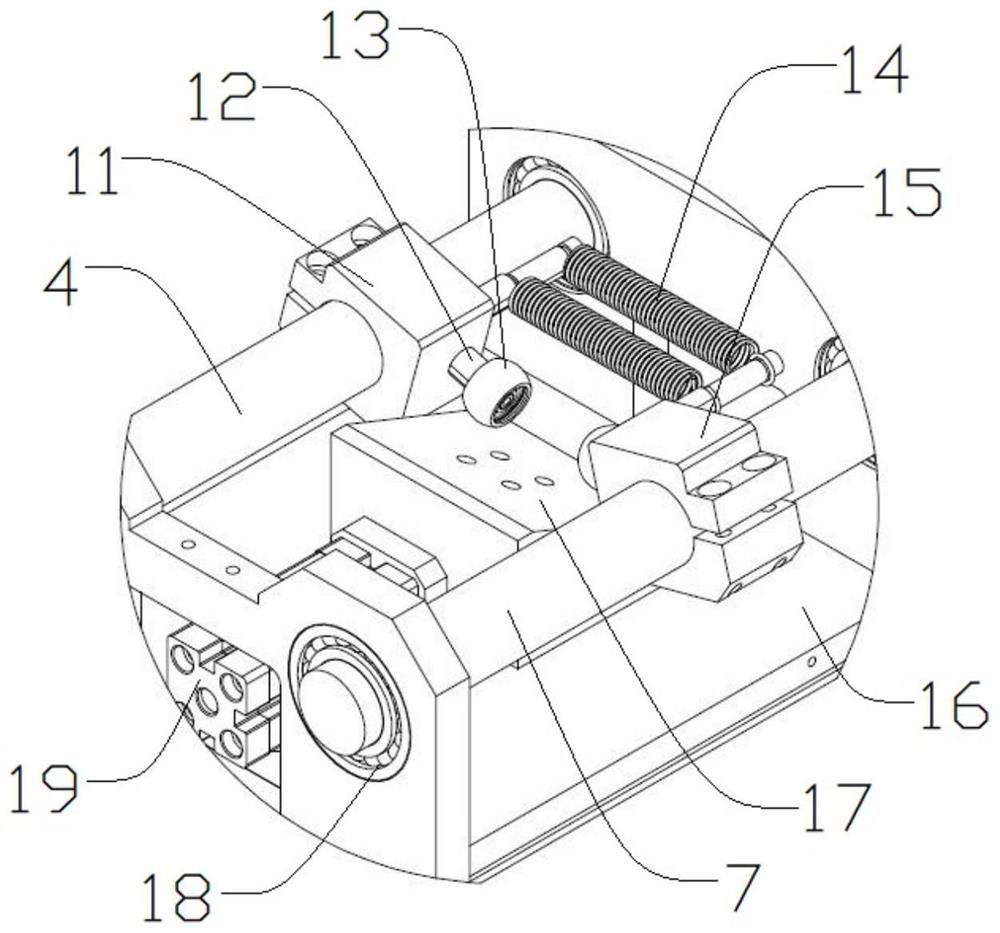

[0032] See figure 2 and Figure 5 The rotational assembly includes a top pilot cylinder 19, a sliding slider 17, a rotating seat, a pin shaft 12, a rolling sphere 13, and a reset tension spring 14, and the top push cylinder 19. The ramp slider 17 rear end surface is solid-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com