Weed damage prevention and control method and device in rice planting process

A rice and weed damage technology, applied in the field of weed damage prevention and control, can solve problems such as high failure rate and complex structure, and achieve the effect of reducing use, reducing structure, and facilitating installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

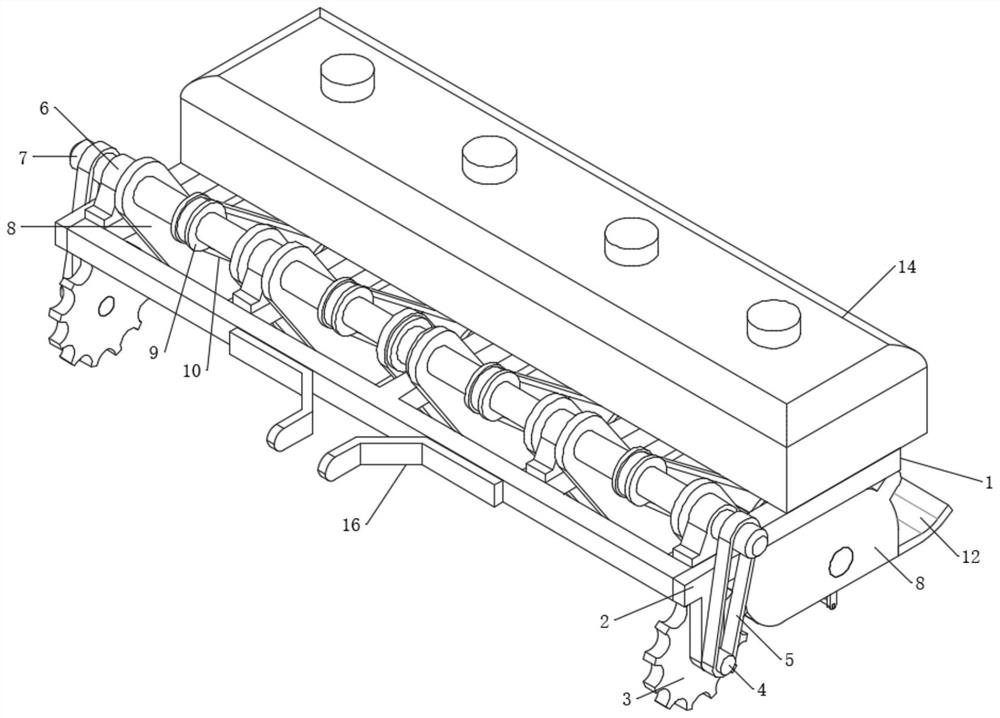

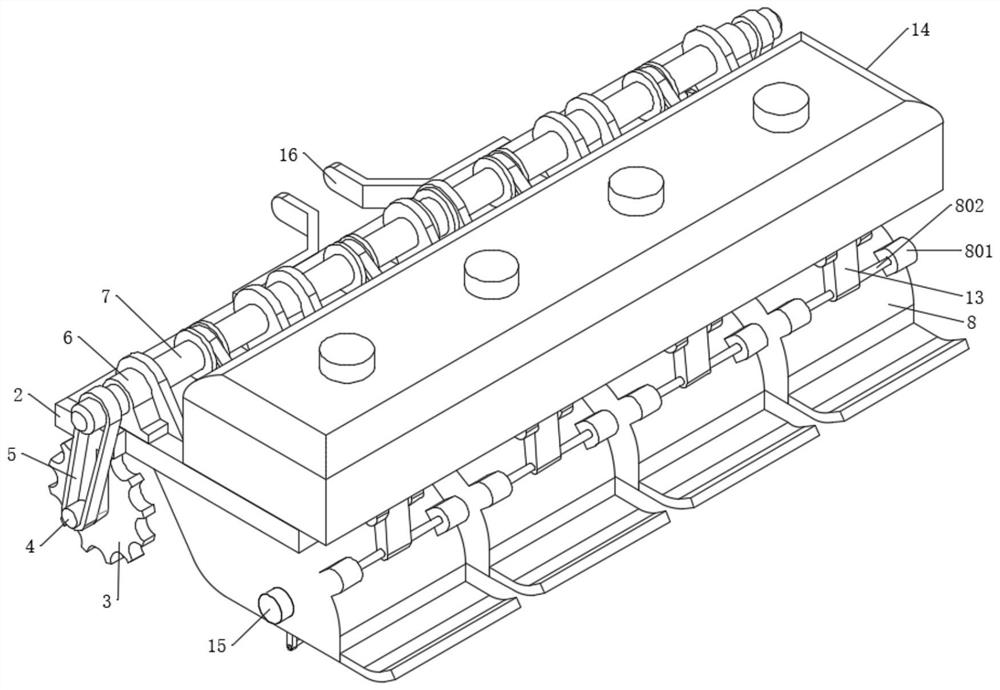

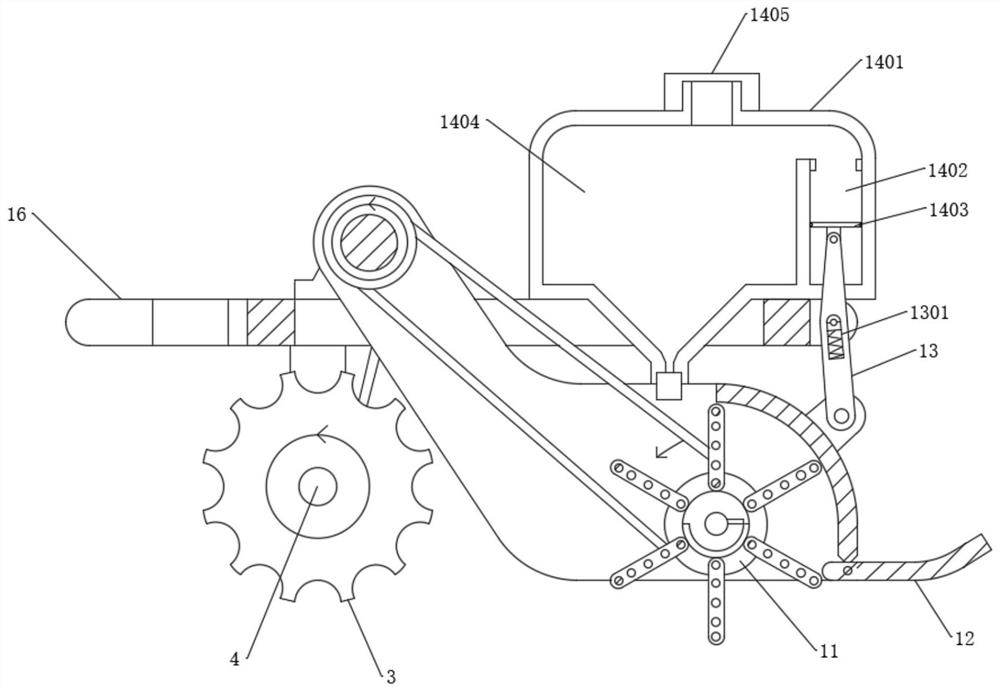

[0033] see Figure 1-6 As shown, the present invention is a weed damage prevention and control device in the rice planting process, comprising a frame body 1, supporting legs 2 are installed on opposite sides of the frame body 1, and pin shafts 4 are installed on the bottom ends of the supporting legs 2, Roller 3 is installed on the pin shaft 4, and several mounting bases 6 are installed on the frame body 1, and the long shaft 7 is installed on the mounting base 6, and the long shaft 7 and the pin shaft 4 are connected by a belt-5 transmission, and the frame body 1 A number of covers 8 are installed inside, one end of the covers 8 is sleeved on the long axis 7, the other end of the covers 8 is connected with the cleaning part 14 installed on the frame 1 through a vibrating rod 13, the inside of the covers 8 A rotating part 11 is installed, and a pulley 9 corresponding to the rotating part 11 is installed on the major axis 7, and the corresponding pulley 9 and the rotating part...

Embodiment 2

[0042] A method for preventing and controlling weeds during rice planting, comprising the steps of:

[0043] Step one, the connecting block 16 that is provided with on the frame body 1 is connected with the driving vehicle, drives the device to move in the paddy field by driving the vehicle;

[0044] Step 2, the roller 3 that is provided with in the motion process rotates, and the rotating roller 3 drives the major axis 7 to rotate through the belt 1 5, and the rotating major axis 7 drives the rotating part 11 to rotate through the belt 2 10;

[0045] Step 3: The rotating rotating part 11 hits the weeds between the rows of rice in the paddy field.

[0046] In the process of using, the connecting block 16 provided on the frame body 1 is connected with the driving vehicle, and the driving device of the driving vehicle moves in the paddy field, and the roller 3 provided with in the motion process rotates, and the rotating roller 3 The long shaft 7 is driven to rotate by the belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com