Corrosion-resistant aerated concrete wallboard capable of enhancing wireless signals and processing method of corrosion-resistant aerated concrete wallboard

An air-entrained concrete and wireless signal technology, which is applied in the field of building assembly and thermal insulation, can solve the problems of complex production process of anti-corrosion coatings, blocking wireless signal transmission, and difficulty in ensuring anti-corrosion quality, so as to solve the problem of peeling off of exterior wall coatings and improve surface strength , The effect of eliminating the shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

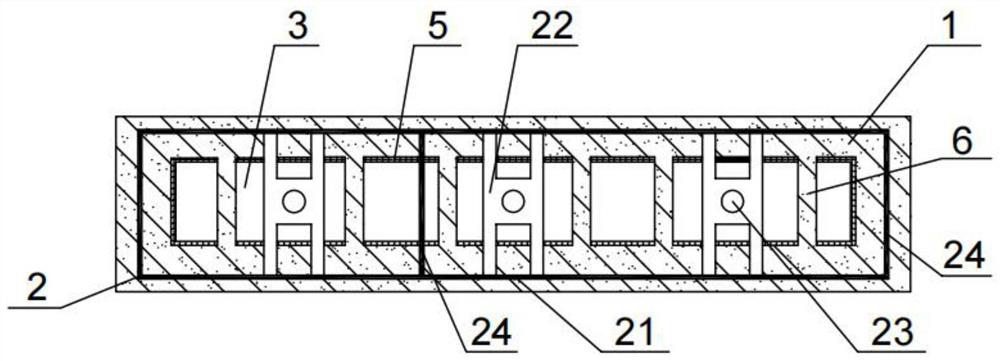

[0040] refer to figure 1 A corrosion-resistant aerated concrete wallboard for enhancing wireless signals is shown, comprising a base plate 1, and a closed cavity 3 is formed inside the base plate 1, and polyurethane insulation material is poured into the cavity 3; the cavity A plurality of connecting columns 6 are also formed inside the cavity 3; and an organic thermal insulation and waterproof layer 5 is provided on the inner walls of the cavity 3 and the plurality of connecting columns 6;

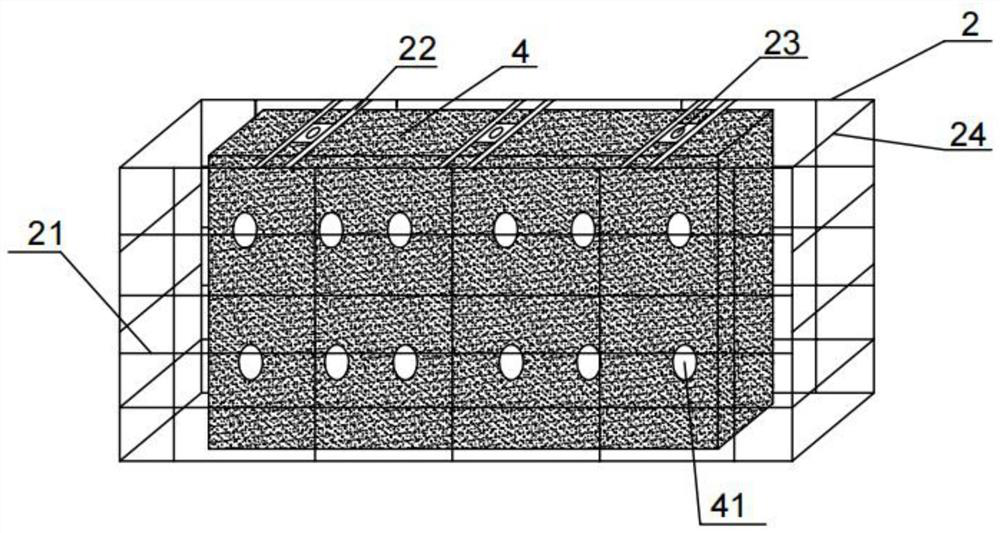

[0041] The base plate 1 is also provided with an FRP mesh cage 2; the FRP mesh cage 2 includes two FRP mesh sheets 21, several FRP connecting pieces 22 and several FRP short ribs 24, and several of the FRP connecting pieces 22 is fixedly connected to the upper and lower ends of the two FRP mesh sheets 21; several short FRP ribs 24 are fixedly connected between the two FRP mesh sheets 21.

[0042] In this embodiment, the organic thermal insulation and waterproof layer 5 is a coating forme...

Embodiment 2

[0056] A method for processing an anti-corrosion aerated concrete wall panel for enhancing wireless signals, comprising the following steps:

[0057] 1) The FRP mesh cage 2 is made of FRP material, and is used for standby; and the cutting hole 23 is opened along the width direction of the FRP mesh cage 2 in the middle of the FRP connecting piece, for inserting and pulling out the steel braze;

[0058] 2) According to the design requirements, the organic hot-melt material 4 is hot-melted or mechanically opened along the thickness direction to form a through hole that is compatible with the cutting hole 23;

[0059] 3) Place the prepared organic hot-melt substance 4 in the FRP cage 2 and fix it;

[0060] 4) Use steel fiber to penetrate the cutting hole 23 and the through hole, and its upper and lower ends pass through the middle part of the FRP connecting piece 22, and fix it, so that the FRP cage 2 is assembled and fixed on the steel braze. shelf;

[0061] 5) Slurry preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com