External wall panel production transmission platform for green building design

An external wall panel and green building technology, applied in the direction of cleaning devices, rollers, conveyor objects, etc., can solve the problems of reducing the service life of the conveying roller, the weight of the external wall panel body, and the simple structure of the transmission platform, so as to ensure the use of Longevity, ensure smoothness, reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

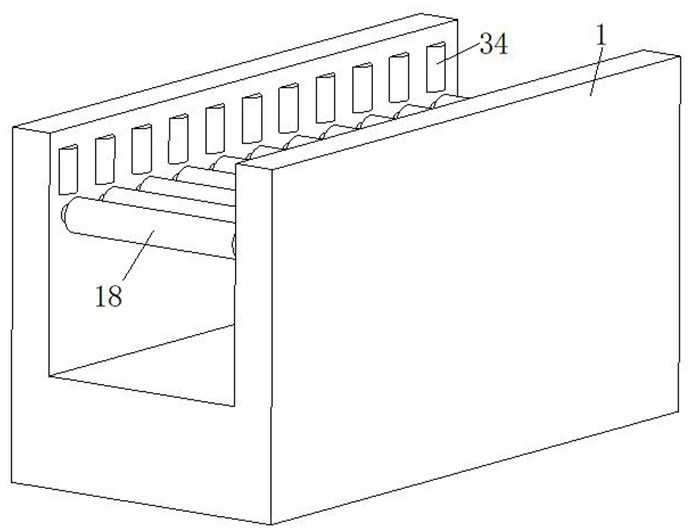

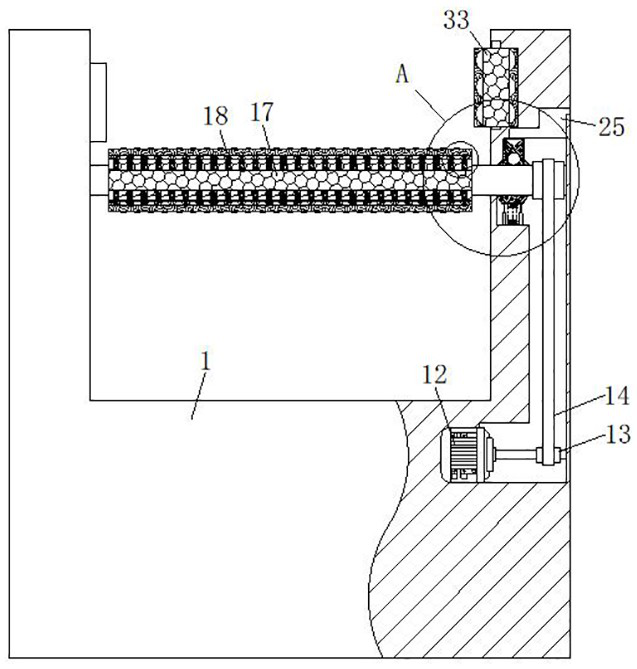

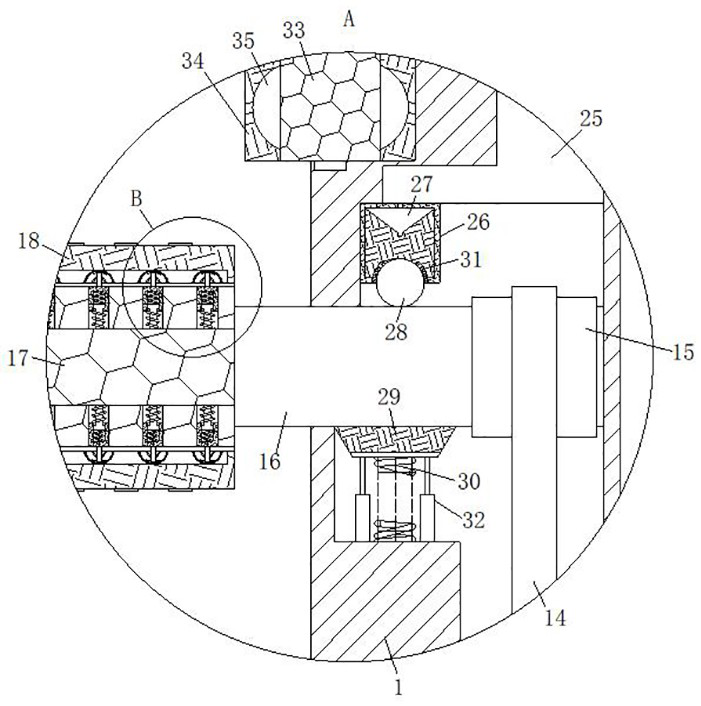

[0027] see Figure 1-4 As shown, a transmission platform for the production of external wall panels designed for green buildings includes a body 1; a motor 12 is fixed inside the body 1; a pulley 13 is fixedly connected to the output end of the motor 12; the body 1 The inner rotation of the rotating rod 16 is connected; the middle part of the rotating rod 16 is fixedly connected with the second pulley 15; the second pulley 15 and the first pulley 13 are connected with the conveyor belt 14; the side end of the rotating rod 16 A conveying roller 17 is affixed; a damping layer 18 is affixed to the conveying roller 17; a limiting rod 22 is affixed inside the conveying roller 17; a pushing block 21 is slidably connected to the limiting rod 22; The inner side wall of the pushing block 21 is fixedly connected with a No. 1 elastic member 23; the pushing block 21 is sleeved with a No. 2 elastic member 24; the top end of the pushing block 21 is fixedly connected with a shock absorbing r...

Embodiment 2

[0036] see Figure 5 As shown in Comparative Example 1, as another embodiment of the present invention, the oil guide block 38 is affixed to the bottom end of the lubrication box 26; during operation, the oil guide block 38 is made of sponge material, and the rotating rod The rotation of 16 will make the ball 28 rotate, and guide the lubricating oil in the lubricating box 26 to the rotating rod 16. The oil guide block 38 can evenly coat the lubricating oil exported by the ball 28 on the rotating rod 16, and pass through the oil guide block 38 The coating range of lubricating oil can be expanded.

[0037] Working principle: When working, the staff starts the motor 12 so that the No. 1 pulley 13 rotates, and the rotation of the No. 1 pulley 13 further makes the conveyor belt 14 rotate. The rotation of the conveyor belt 14 will drive the No. 2 pulley 15 to rotate, and the rotation of the No. 2 pulley 15 The rotation makes the rotating rod 16 rotate, and the rotation of the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com