Low-layer assembly type profiled steel sheet light-concrete composite wallboard, connecting structure and construction method

A technology of profiled steel plates and composite wall panels, which is applied to truss structures, floor slabs, building components, etc., can solve the problems of hollowness, low construction efficiency, and high automation costs, and achieve simple node structure, convenient construction, and improved automation horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

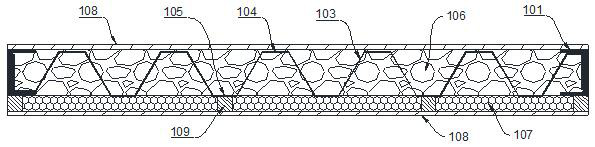

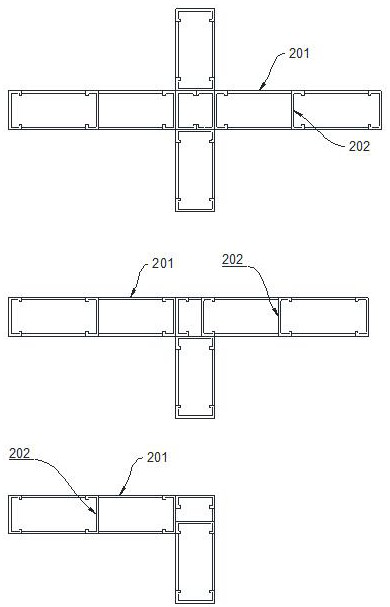

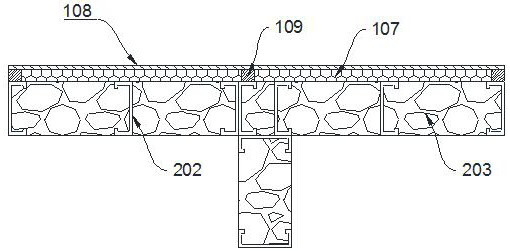

[0055] Such as Figure 1-Figure 5 As shown, a low-level assembled profiled steel plate 103 light-mixed composite wall panel 1 includes two vertical frames 101 arranged vertically and a horizontal frame 102 arranged horizontally, and the vertical frame 101 and the horizontal frame 102 form a frame structure, at least one laminated steel plate 103 is provided in the frame structure, and the two ends of the profiled steel plate 103 are connected with the vertical frame 101; the profiled steel plate 103 is formed with several vertically arranged and alternately distributed The outer convex portion 104 and the inner concave portion 105; the two sides of the profiled steel plate 103 are provided with a filling structure layer 106, and the side of the filling structure layer 106 corresponding to the outer convex portion 104 or the inner concave portion 105 is sequentially provided with Thermal insulation structure layer 107 and panel layer 108, its other side is provided with panel l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com