Engine blade film temperature sensor and preparation method thereof

An engine blade, film temperature technology, applied in the direction of thermometers, thermometers and instruments with directly sensitive electrical/magnetic components, etc., can solve the problem of interference with blade heat flow and temperature field, limited temperature measurement accuracy of sensors, and lead terminals. Additional potential difference and other issues to achieve the effect of improving the measurement temperature and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

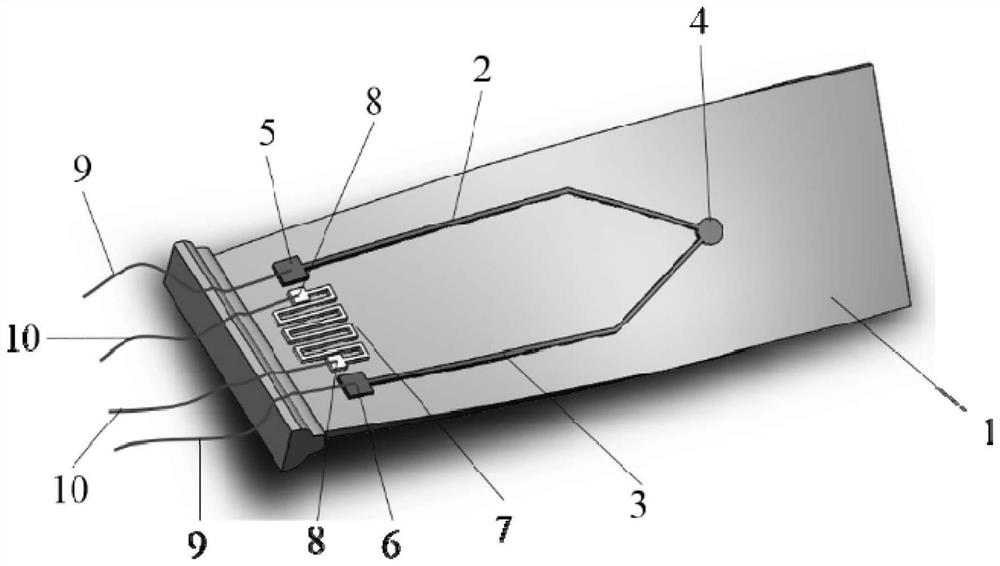

[0039] Such as figure 1 As shown, the engine blade film temperature sensor of the present embodiment includes the engine blade 1, and the engine blade 1 is provided with an insulating layer and a thermocouple film in sequence, and the thermocouple film is formed by lapping thermocouple A2 and thermocouple B3, and the overlapping Part of the thermocouple hot end 4 is used as the temperature point to be measured. The other ends of the thermocouple A2 and the thermocouple B3 are respectively provided with a pad A5 and a pad B6 to form a thermocouple cold end; between the pad A5 and the pad B6 A compensation resistance film 7 for measuring the temperature of the cold junction of the thermocouple is provided.

[0040] In this embodiment, the compensation resistor film 7 is a Pt film with a thickness of 1 μm.

[0041] In this embodiment, the two ends of the compensation resistor film 7 are also provided with pads C8, the material pads C8 of the pads C8 are on the same straight line a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com