Sectional type fuel cell clamp

A fuel cell, segmented technology, applied in fuel cells, circuits, electrical components, etc., can solve the problem of high experimental costs, and achieve the effects of improving performance stability, reducing costs, and uniform relative humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the specific embodiments of the accompanying drawings, but the protection scope of the present invention is not limited thereto.

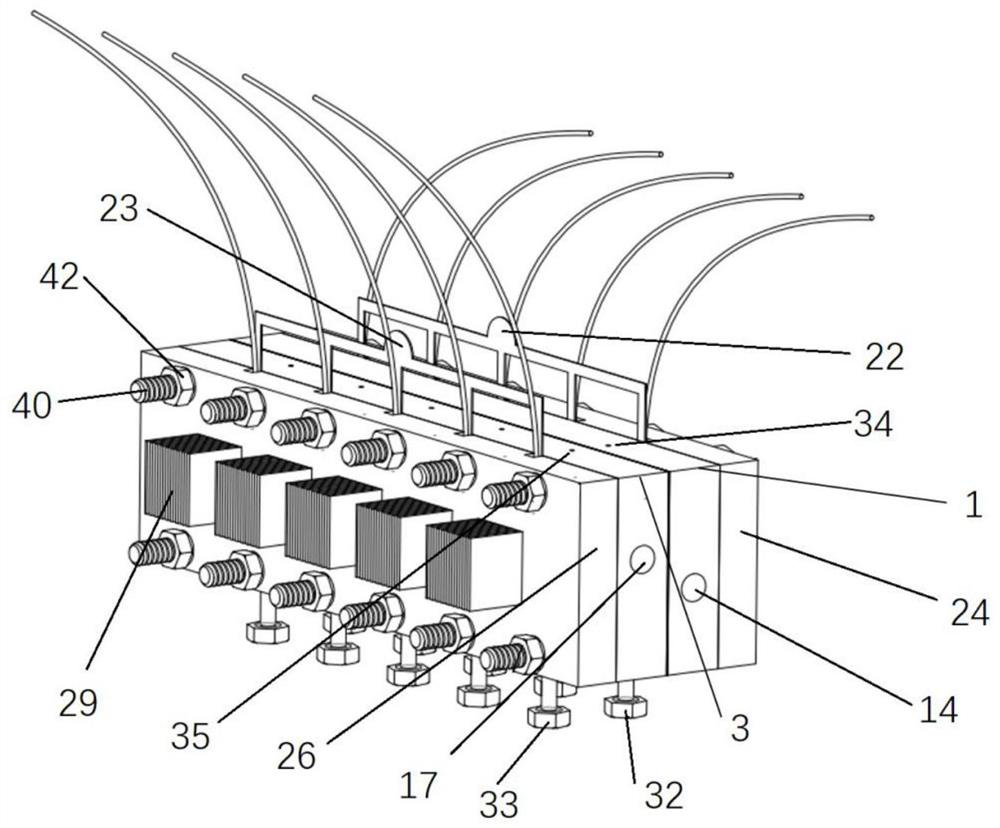

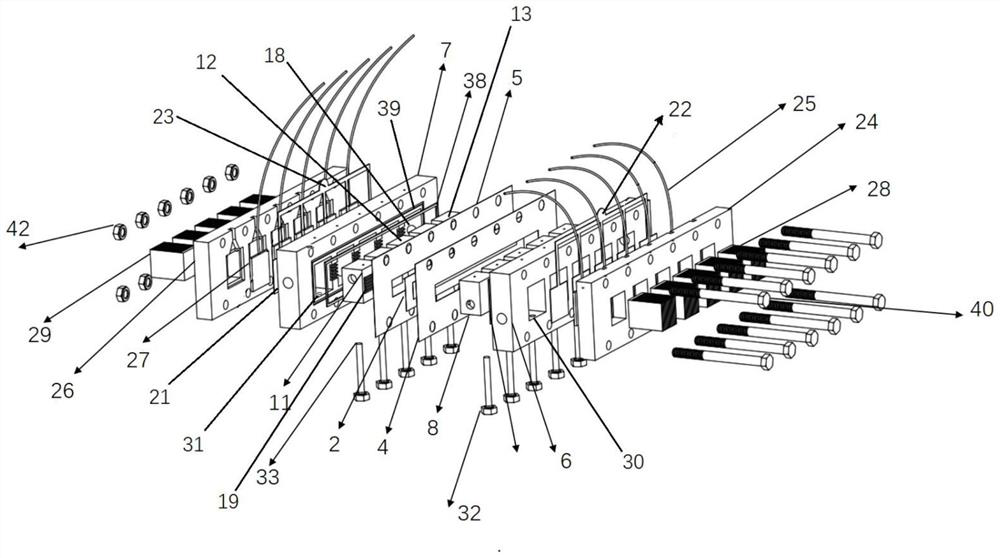

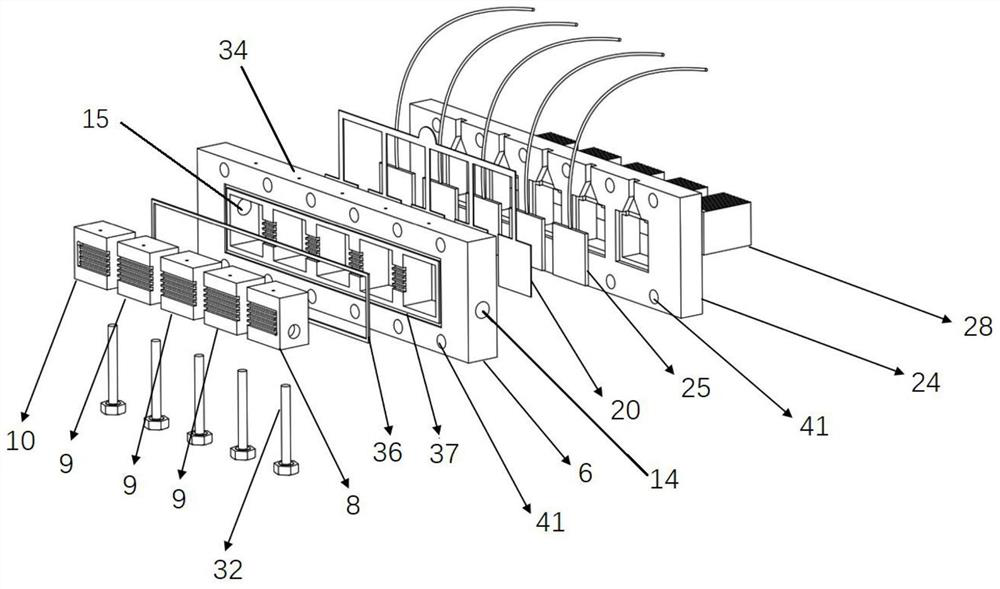

[0037] figure 1 , 2 , 3, 4 and 5, the segmented fuel cell fixture includes a cathode terminal 1, a membrane electrode 2 and an anode terminal 3; the cathode terminal 1 and the anode terminal 3 are symmetrical structures, and the cathode terminal 1 and the anode terminal 3 The structures are the same, and the cathode terminal 1 and the anode terminal 3 are symmetrically installed on both sides of the membrane electrode 2; the catalyst concentration on the membrane electrode 2 is distributed in a gradient.

[0038] A cathode gasket 4 is provided between the cathode terminal 1 and the membrane electrode 2; an anode gasket 5 is provided between the anode terminal 3 and the membrane electrode 2; the cathode gasket 4 and the anode gasket 5 are used to clamp the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com