Method for carrying out deformation characterization on human tongue based on equivalent thickness bulk modulus

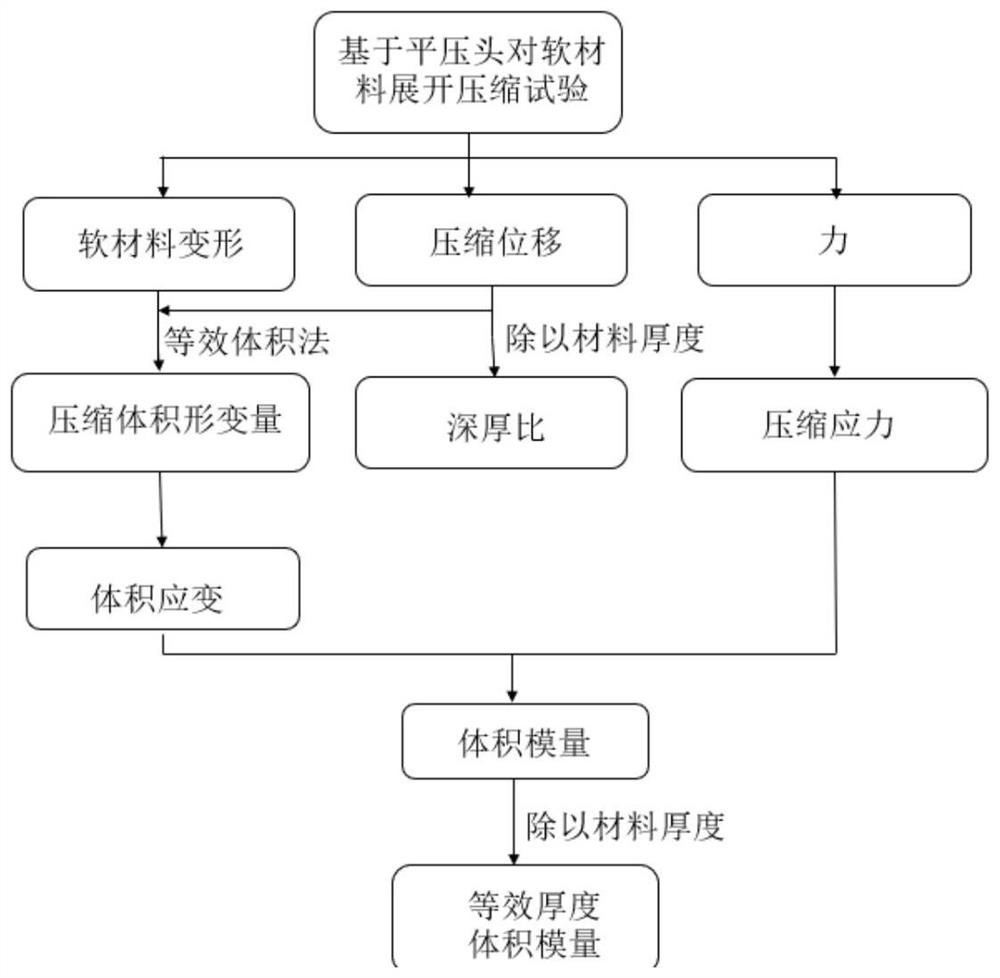

A technology of bulk modulus and characterization, which is applied in the direction of measuring devices, strength characteristics, and the use of stable tension/pressure to test the strength of materials, etc., can solve problems such as three-dimensional deformation of soft materials, and achieve the effect of eliminating influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

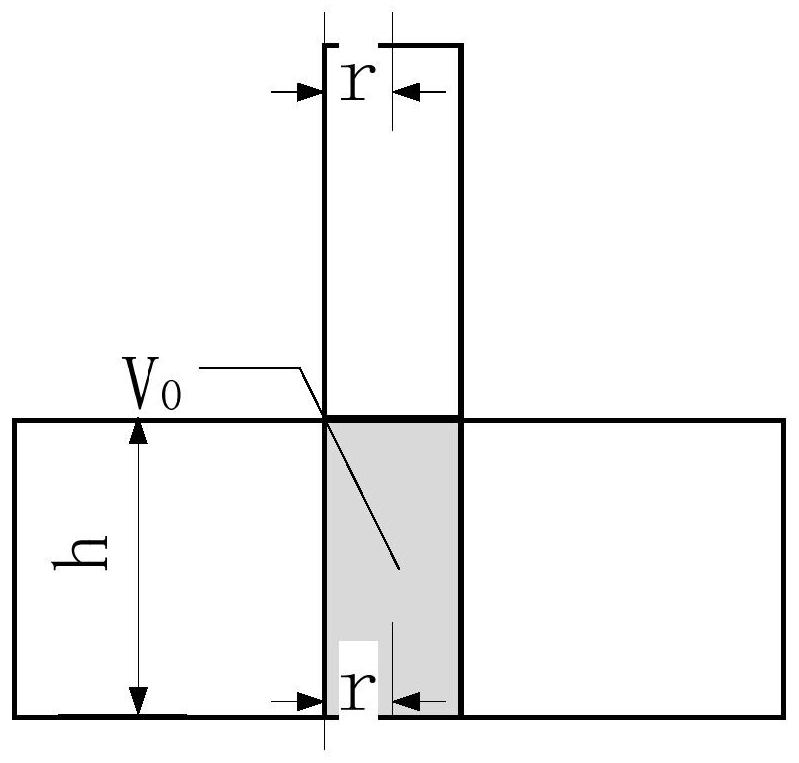

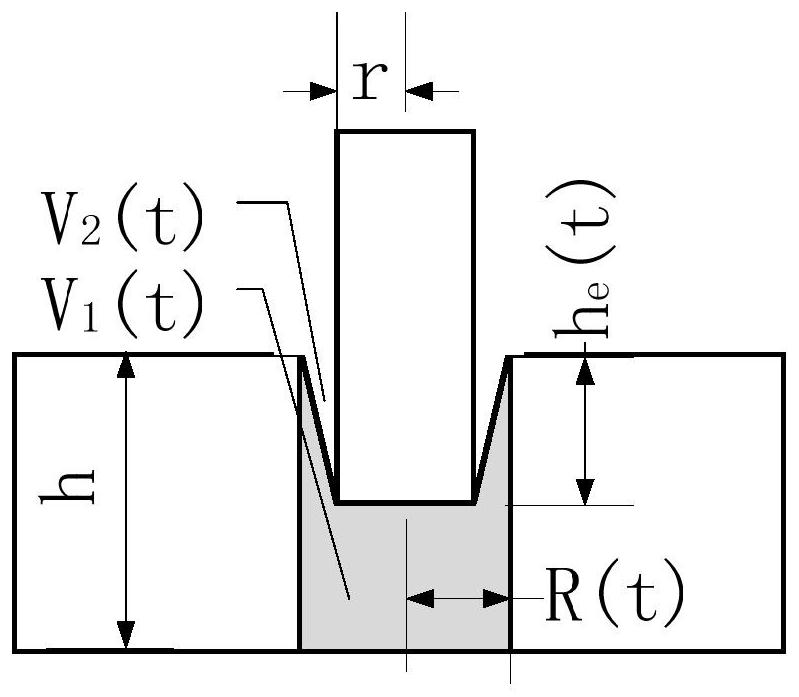

[0065] Preferred embodiment 1: Deformation characterization of PDMS soft materials using IVMET

[0066] According to this preferred embodiment, first, the bionic soft material polydimethylsiloxane (PDMS) is used as the test material, and the mass ratio of the base liquid and the curing agent is 25:1, and the same process is used to prepare four thicknesses For different soft material samples, the sample thicknesses are 5.93mm, 4.83mm, 4.16mm and 3.21mm respectively.

[0067] According to this preferred embodiment, according to the above-mentioned specific steps of the IVMET-based soft material characterization method of the present invention, first, the obtained four kinds of soft material samples are successively placed on the MFT-5000 friction and wear testing machine, using a 10N sensor and a diameter of 3.2 mm flat indenter for compression test to obtain the force-displacement value curve; secondly, the compressive stress is calculated according to the force-displacement v...

Embodiment 2

[0071] Preferred embodiment 2: Deformation characterization of SEEPS thermoplastic elastomer soft material (SEEPS-TPE) using IVMET

[0072] According to this preferred embodiment, the SEEPS-TPE soft material is prepared by molding method, and the prepared samples have seven samples whose paraffin oil addition amounts are (0, 50, 100, 150, 200, 250, 300) phr respectively, and the obtained seven The samples were successively placed on the MFT-5000 friction and wear testing machine for compression tests using a 10N sensor and a flat indenter with a diameter of 3.2mm. Since it is difficult to obtain samples with the same thickness by molding method, the characterization method based on IVMET is used to characterize SEEPS-TPE with different paraffin oil additions to analyze the influence of different paraffin additions on SEEPS-TPE, see Figure 4 ( a) and Figure 4(b).

[0073] From the data in Figure 4(a) and Figure 4(b), it can be seen that with the increase of paraffin oil additi...

Embodiment 3

[0074] Preferred embodiment 3: Utilize IVMET to carry out deformation characterization to the SEEPS-TPE soft material that adds Talc

[0075] According to this preferred embodiment, first add quantitative Talc and antioxidant (1phr) to paraffin oil (140phr) and mix uniformly to form a suspension, then mix and stir the SEEPS material and suspension uniformly, and place for 8 hours. Finally, Talc-SEEPS-TPE was prepared by molding method, and the prepared samples were Talc-SEEPS-TPE with Talc addition amount of (0, 5, 10, 15, 20, 25, 30) phr. Put the obtained seven kinds of samples on the MFT-5000 friction and wear testing machine successively, and use the 10N sensor and the flat indenter with a diameter of 3.2mm to carry out the compression test. Talc-SEEPS-TPE with different Talc additions was characterized by IVMET to analyze the effect of different Talc additions on SEEPS-TPE, as shown in Figure 5(a) and Figure 5(b).

[0076] From the data in Figure 5(a) and Figure 5(b), it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com