Steaming and baking all-in-one machine

An all-in-one machine, steaming and baking technology, which is applied to steam cooking utensils, roasters/barbecue grids, cooking utensils, etc., can solve the problems of large working noise of circulating fans, increased working noise of cooking devices, and small air volume, etc., to achieve increased Large effective sweeping area, improving cooking efficiency and ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

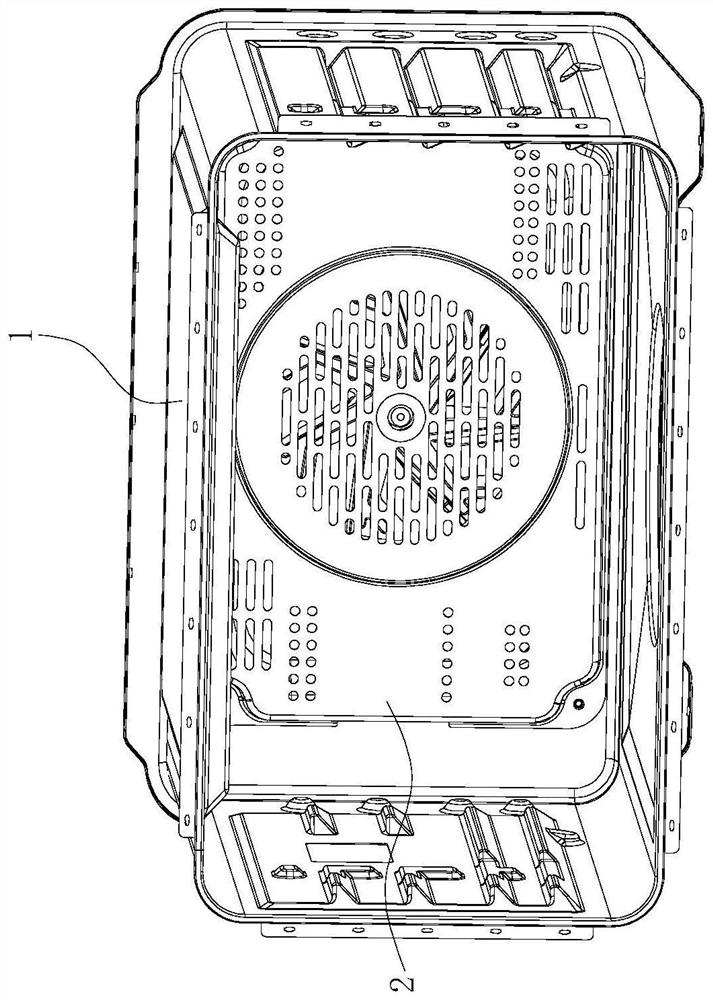

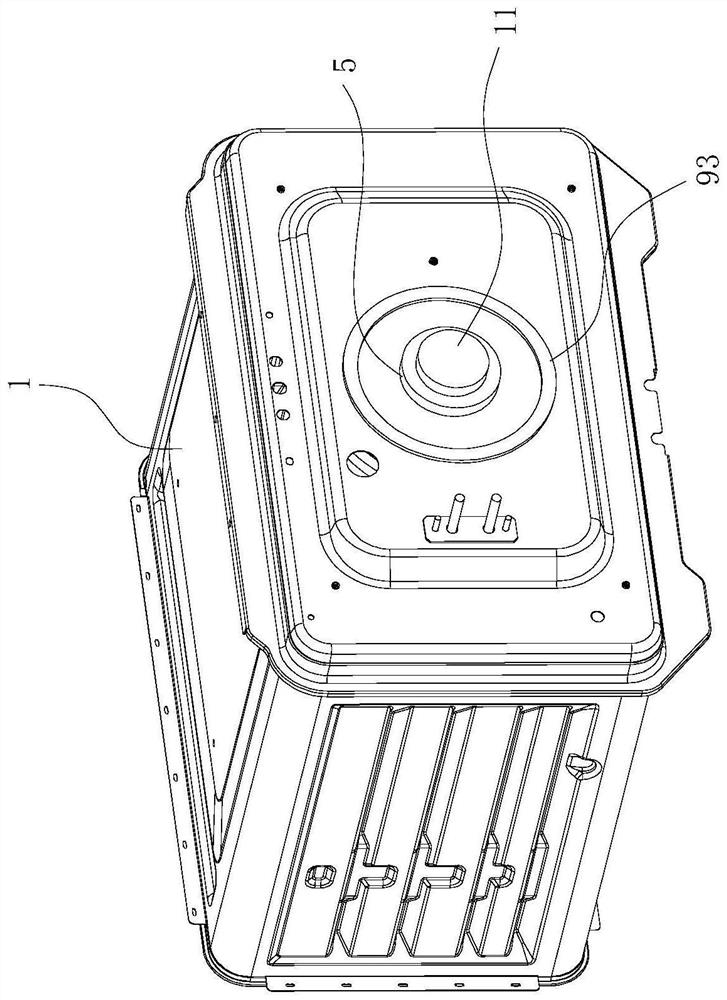

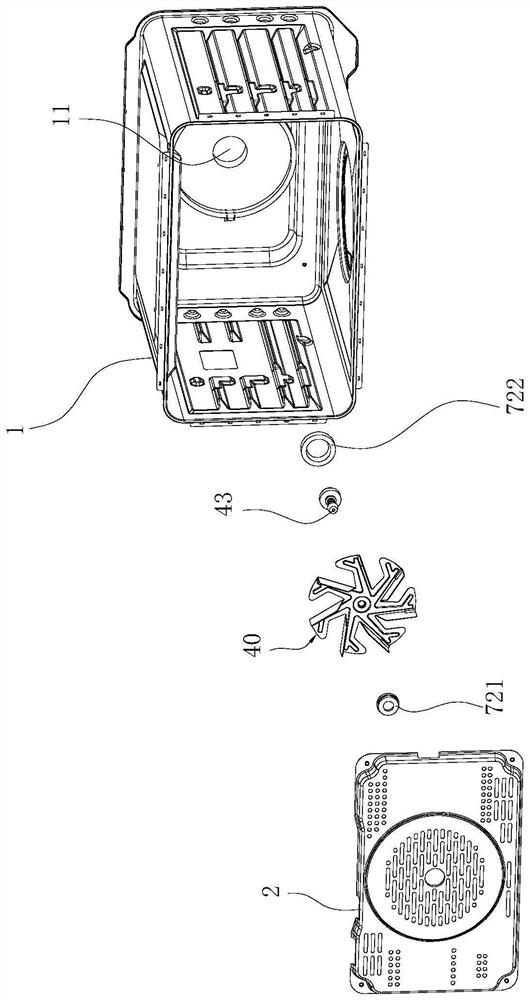

[0044] Such as Figure 1-8 as well as Figure 11 and Figure 12 As shown, a steaming and baking integrated machine includes an inner container 1, a circulating fan 4 is installed on the back plate of the inner container 1, and a hot air baffle 2 is arranged on the rear side of the inner cavity of the inner container 1, and the hot air baffle 2 The hot air chamber 20 is surrounded by the backboard of the inner container 1 , the impeller 40 of the above-mentioned circulating fan 4 is located in the hot air chamber 20 , and the outer periphery of the impeller 40 is provided with a heating pipe 3 .

[0045] The circulation fan 4 further includes a rotating shaft 43 extending forward and backward, and the middle part of the rotating shaft 43 is connected to the central shaft hole 411 of the hub plate 41 . In the prior art, the rotating shaft 43 of the circulating fan 4 is generally set on the inner tank 1 through a hole on the back plate of the inner tank 1 , and the opening of t...

Embodiment 2

[0057] Such as Figure 9 , Figure 10 as well as Figure 12 As shown, the difference from Embodiment 1 is that in this embodiment, the inner peripheral surface of the stator 5 and the outer peripheral surface of the rotor 6 are both shaped surfaces. By designing the special-shaped surface, an auxiliary force can be provided for the interaction between the stator 5 and the rotor 6, so as to avoid excessive coil load in the stator 5 during the start-up of the circulation fan 4 and prolong the service life of the stator 5. Specifically, the inner peripheral surface of the stator 5 and the outer peripheral surface of the rotor 6 are tooth-shaped, which can better provide auxiliary force for the interaction between the stator 5 and the rotor 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com