Traditional Chinese medicine grinding equipment for processing in pharmaceutical factory

A technology of traditional Chinese medicine and equipment, applied in the field of traditional Chinese medicine grinding equipment for processing in pharmaceutical factories, can solve the problems of slow manual grinding speed, time-consuming and laborious, etc., and achieve the effect of convenient collection and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

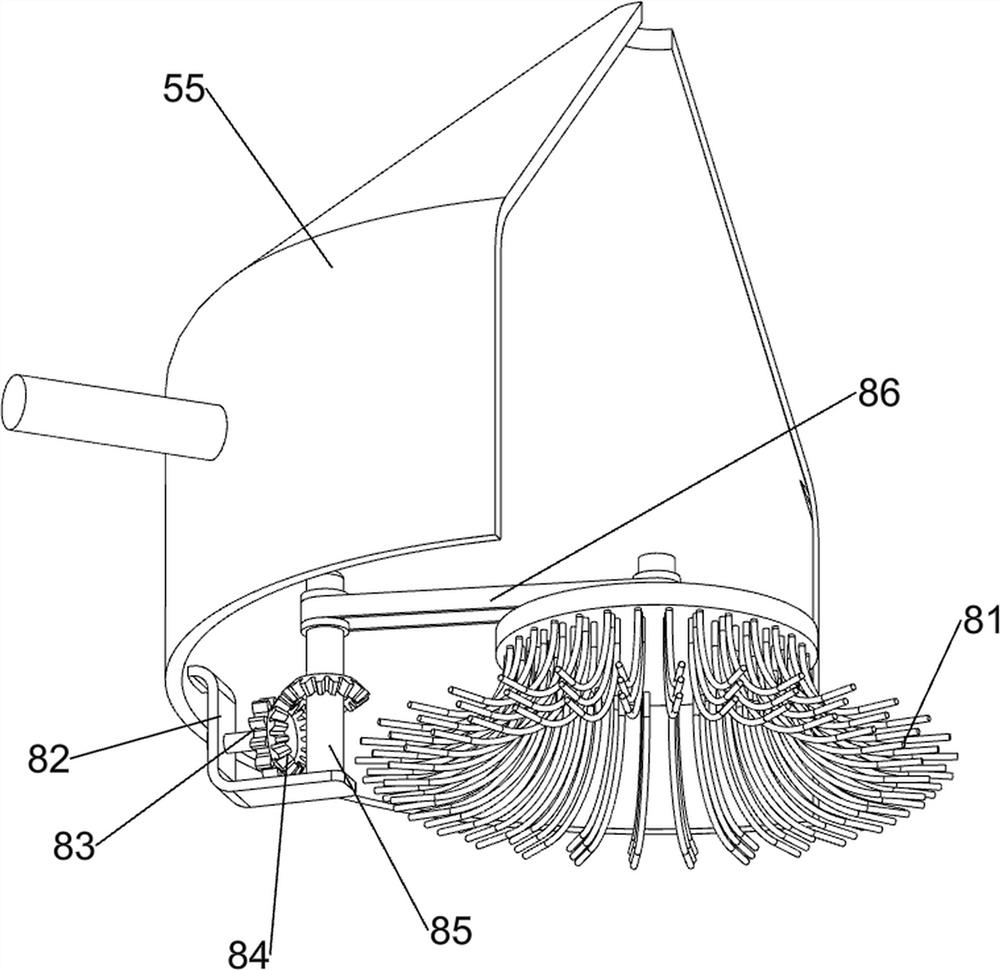

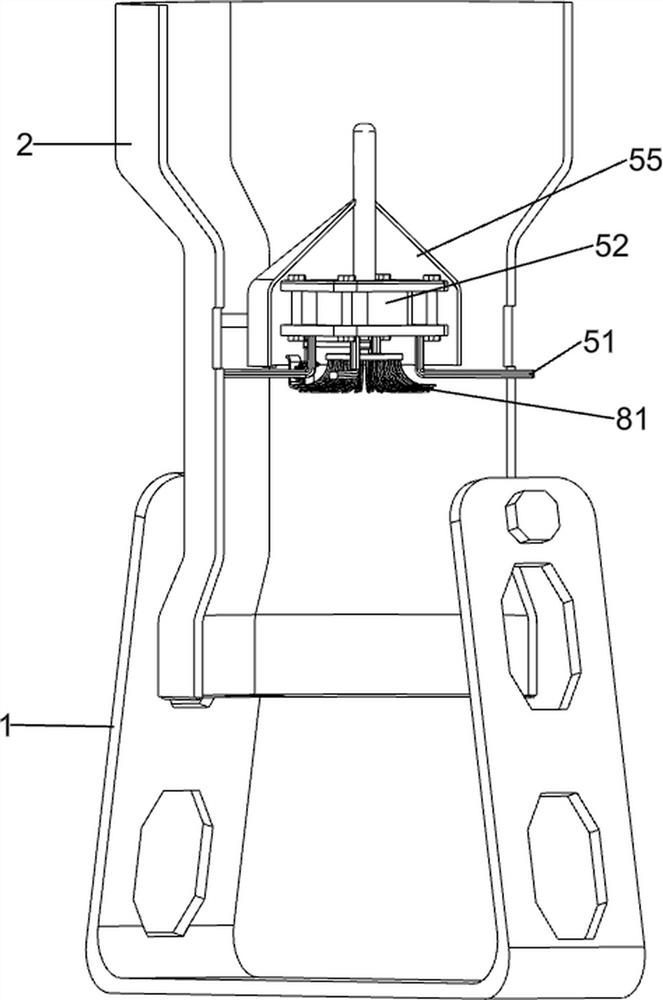

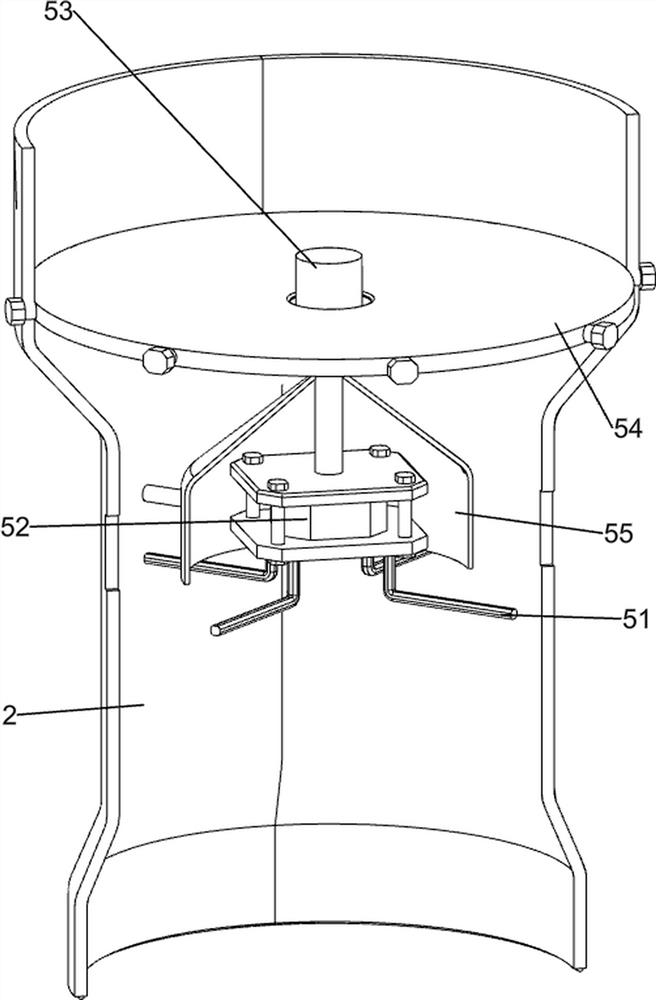

[0034] A traditional Chinese medicine grinding equipment for processing in a pharmaceutical factory, such as Figure 1-6 As shown, it includes a bracket 1, a casing 2, a cover 3, a steel knife 4, a grinding power mechanism 5, and a filter mechanism 6. The upper side of the bracket 1 is fixed with a casing 2 by bolts, and a cover 3 for blocking dust is placed on the top of the casing 2. , the middle part of the inner side of the shell 2 is provided with a filter mechanism 6, and the upper side of the shell 2 is provided with a grinding power mechanism 5, and the grinding power mechanism 5 and the filter mechanism 6 cooperate with the grinding power mechanism 5 to be provided with a steel knife 4 in a rotating manner, and the steel knife 4 is provided with a steel knife There are six cutting knives, which can quickly chop the effect of Chinese medicine.

[0035] In pharmacy, in order to cure the disease quickly, people will boil Chinese medicine for treatment. When people need t...

Embodiment 2

[0041] On the basis of Example 1, such as Figure 1-2 and Figure 7-11 Shown, also comprise vibration mechanism 7, vibration mechanism 7 comprises rotating rod 71, wedge-shaped piece 72 and fixed ring 73, is fixedly connected with rotating rod 71 on the output shaft of motor 52, and protective cover 55 inside is welded with fixed ring 73, fixed The ring 73 is rotationally connected with the rotating rod 71 , and a wedge block 72 is welded on the left side of the filter screen 62 , and the wedge block 72 contacts and cooperates with the rotating rod 71 .

[0042] When the output shaft of the motor 52 rotated, the rotation of the output shaft of the motor 52 would drive the rotating rod 71 to rotate. When 71 continued to rotate, the rotating rod 71 was not in contact with the wedge block 72, so that the filter screen 62 automatically moved upwards to reset, and then drove the wedge block 72 to move upwards to reset, and then realized the effect of automatically shaking the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com