Method for separating lithium concentrate transformation roasting material before acidification or alkalization

A technology that transforms roasting and separation methods. It is applied to the improvement of process efficiency and grain processing, and can solve the problems of reduced market competitiveness, high production costs, and large environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for separating lithium concentrate transformed roasting material before acidification or alkalization, comprising the following steps:

[0022] S1, roasting: 100 g Li 2 Lithium concentrate with an O content of 4% is placed in a muffle furnace, heated to 1000° C., and sintered for 1 hour to obtain a roasted material;

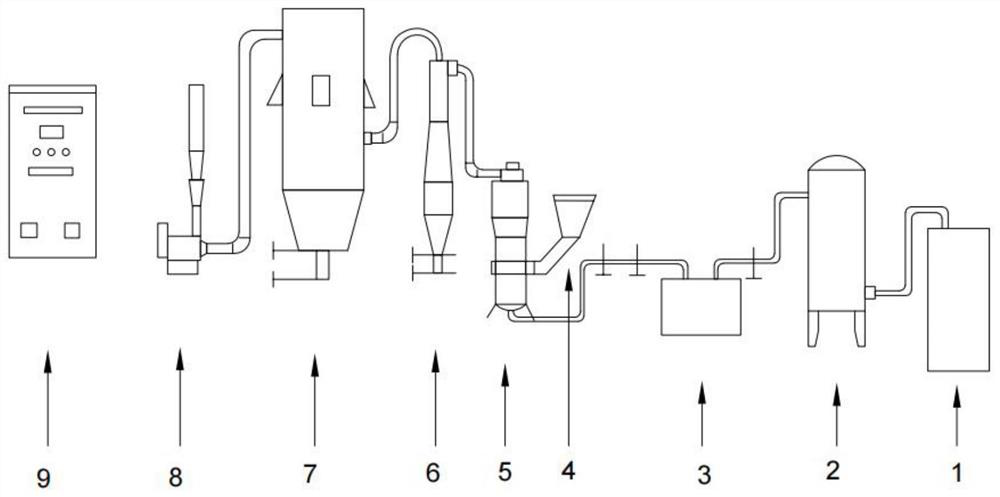

[0023] S2, crushing and separation: the roasted material obtained in step S1 is crushed and separated by the airflow crushing and separation system; the fine powder under the 150-mesh sieve is the β-type lithium concentrate powder for lithium salt production; the coarse powder on the 150-mesh sieve The material is lithium-containing feldspar powder. The jet pulverization and separation system includes a jet pulverization classifier; the gas pressure of the jet pulverization separation system is 1kg / cm 2 , FM crushing motor is 50 Hz.

[0024] After separation, obtain 60 grams of lithium-containing feldspar powder and 38 grams of lithium salt pro...

Embodiment 2

[0026] A method for separating lithium concentrate transformed roasting material before acidification or alkalization, comprising the following steps:

[0027] S1, roasting: 100 g Li 2 The spodumene ore with an O content of 5.8% is placed in a roasting furnace, heated to 1100°C, and sintered for 0.5h to obtain a roasted material;

[0028] S2, crushing and separation: the roasted material obtained in step S1 is crushed and separated by the airflow crushing and separation system; the fine powder under the 150-mesh sieve is the β-type lithium concentrate powder for lithium salt production; the coarse powder on the 150-mesh sieve The material is lithium-containing feldspar powder. The jet pulverization and separation system includes a jet pulverization classifier; the gas pressure of the jet pulverization separation system is 10kg / cm 2 , FM motor is 20 Hz.

[0029] After separation, obtain 66 grams of lithium-containing feldspar powder and 32 grams of lithium salt production wi...

Embodiment 3

[0031] A method for separating lithium concentrate transformed roasting material before acidification or alkalization, comprising the following steps:

[0032] S1, roasting: 100 g Li 2 The spodumene ore with an O content of 5.8% is placed in a roasting furnace, heated to 1050° C., and sintered for 40 minutes to obtain a roasted material;

[0033] S2, crushing and separation: the roasted material obtained in step S1 is crushed and separated by the airflow crushing and separation system; the fine powder under the 150-mesh sieve is the β-type lithium concentrate powder for lithium salt production; the coarse powder on the 150-mesh sieve The material is lithium-containing feldspar powder. The jet pulverization separation system includes a jet pulverization classifier; the gas pressure of the jet pulverization separation system is 7kg / cm 2 , FM motor is 40 Hz.

[0034] After separation, 72 grams of lithium-containing feldspar powder and 27 grams of β-type hectorite powder for li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com