Automatic glazing and tableware surface glaze detection equipment for ceramic tableware

A technology of automatic glazing and testing equipment, applied in the related fields of ceramic glaze, can solve the problems affecting ceramic tableware, surface glaze damage, and difficulty in ensuring the safety and health of ceramic tableware consumers, and achieves the effect of simplifying the structure and improving the consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

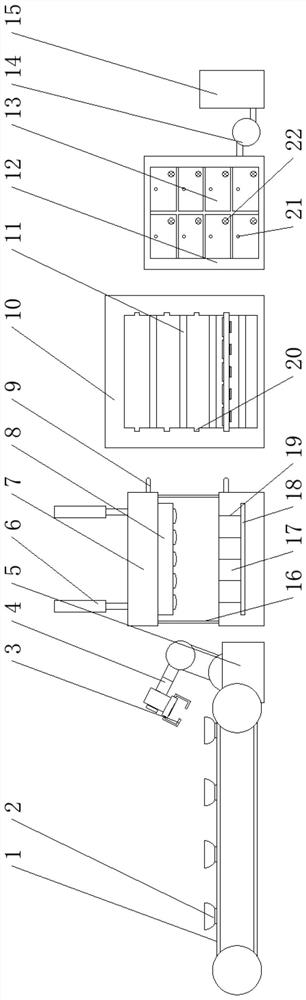

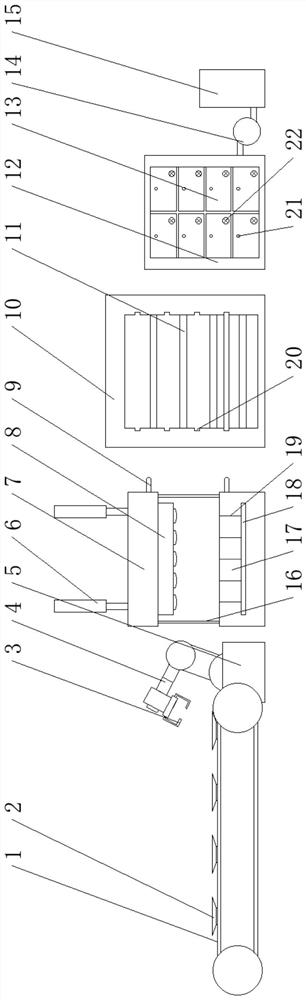

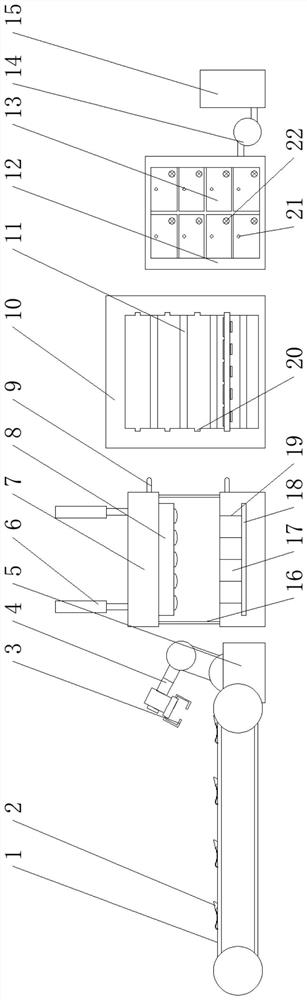

[0047] see Figure 1-10 , an automatic glazing of ceramic tableware and tableware surface glaze detection equipment, comprising a conveyor belt 1, ceramic tableware 2 is distributed at equal intervals on the conveyor belt 1, the ceramic tableware 2 is a tableware body that has not been glazed on the surface layer, and the ceramic tableware 2 The types include bowls, dinner plates, spoons and chopsticks, which are suitable for the diversified production of manufacturers. A base 5 is provided on the forward direction of the conveyor belt 1, and a manipulator 4 is installed on the base 5. When the manipulator 4 is far away from the base 5 A mechanical claw 3 is installed at one end, a glaze coating groove 17 is provided on the side of the base 5 away from the conveyor belt 1, a guide rod 16 is installed at the corner of the glaze coating groove 17, and a hydraulic cylinder is arranged above the glaze coating groove 17 6. A lower pressure piece 7 is connected to the telescopic rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com