Automatic testing device for lithium battery

An automatic test and lithium battery technology, applied in the direction of measuring devices, measuring electricity, measuring electric variables, etc., can solve the problems of long time, influence, and slow detection speed of lithium batteries, so as to speed up the feeding speed, reduce labor intensity, and detect good precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

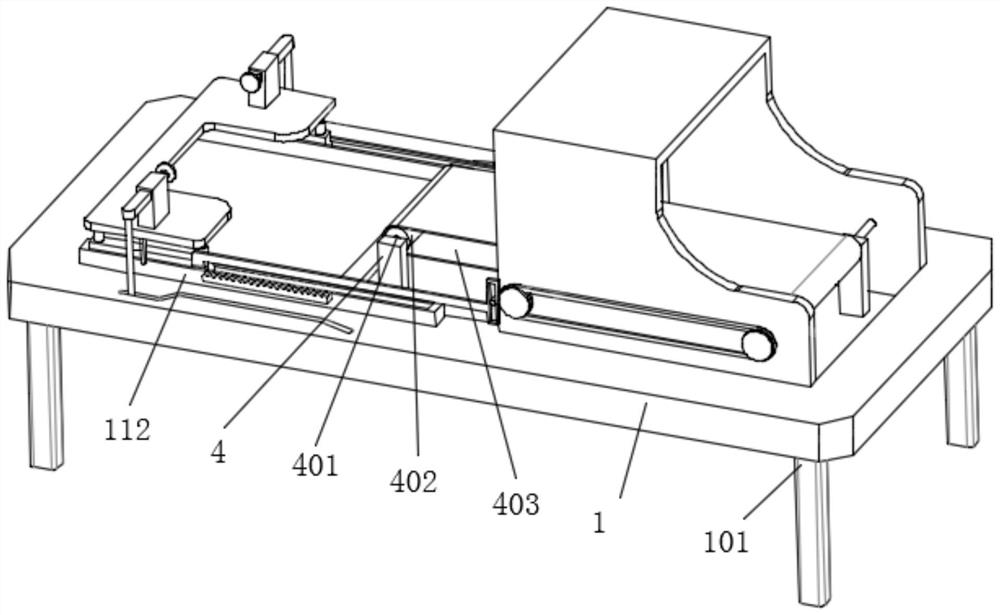

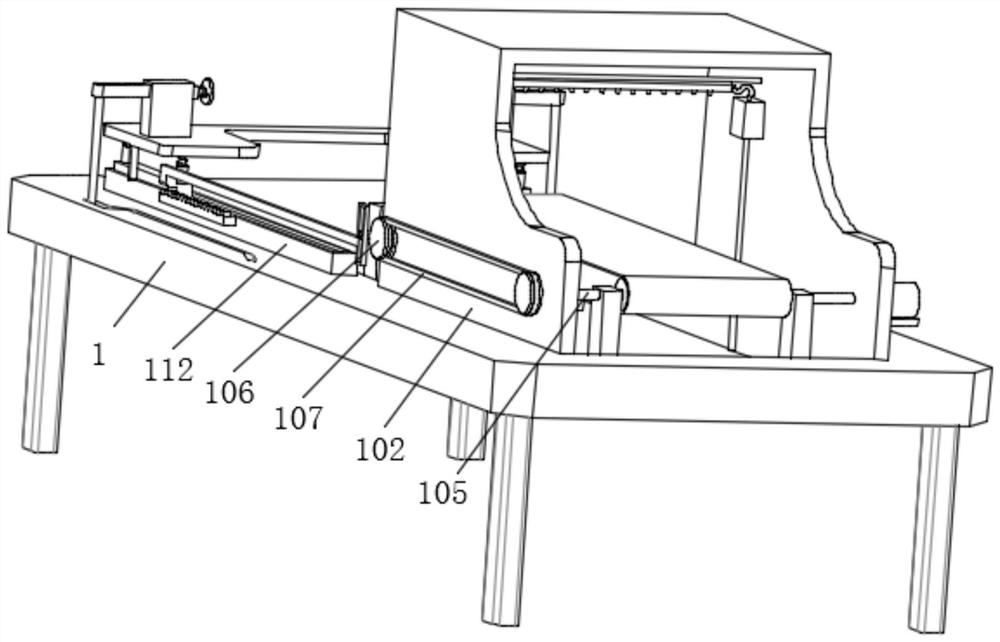

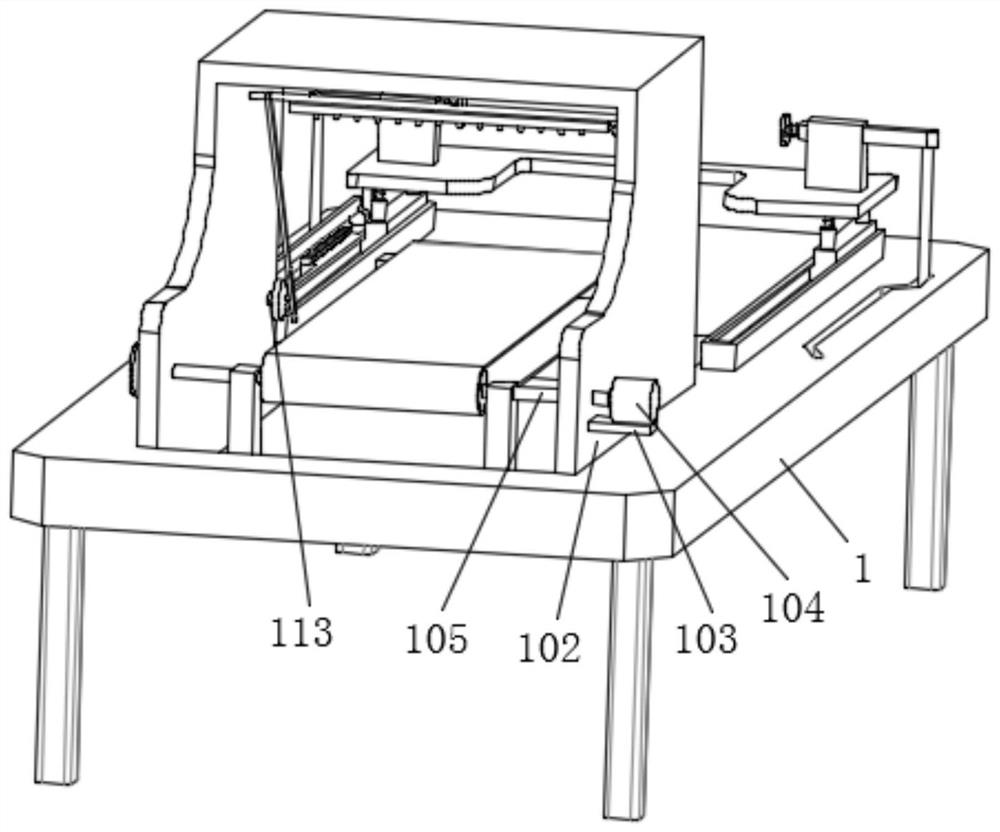

[0040] Example: Reference Figure 1-8 The shown automatic test device for lithium batteries includes a detection workbench 1, and support columns 101 are fixedly installed around the bottom of the detection workbench 1, and the top of the detection workbench 1 is provided with shock-resistant An automatic detection component for detection and waterproof detection, the automatic detection component includes a connected clamping anti-seismic detection unit and a waterproof detection unit, the clamping anti-seismic detection unit includes a connected automatic reciprocating feeding element, battery clamping element and vibration element, waterproof detection The unit includes a connected uniform water spray element and a battery conveying element. During the process of feeding the lithium battery by the automatic reciprocating feeding element, the battery clamping element clamps the lithium battery and performs an anti-seismic test through the vibrating element. The components ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com