AGV online fault prediction system and method based on Kalman filtering

A Kalman filtering and fault prediction technology, applied in the direction of prediction, measurement device, measurement of electrical variables, etc., can solve the problems of unsatisfactory fault prediction effect, signal analysis interference, vibration signal doped with background noise, etc., to achieve reasonable and reliable prediction. As a result, the effect of reducing equipment failure rate and reducing operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

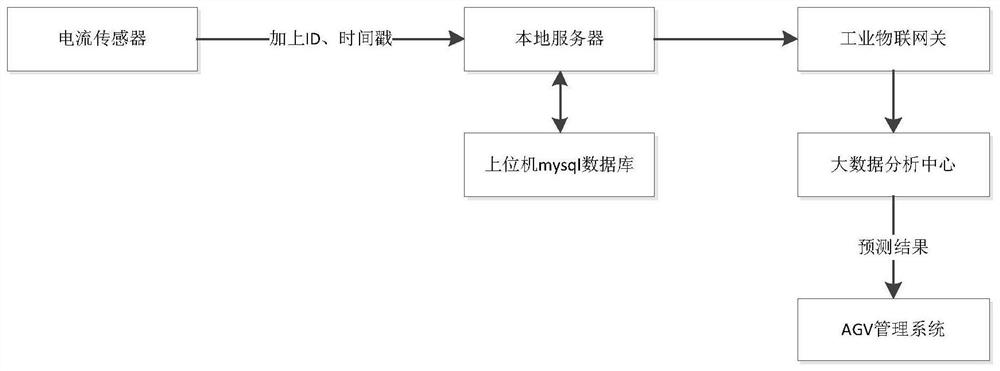

[0016] This invention collects the real-time data of AGV based on the industrial Internet, and the server generates a fault prediction signal according to the monitoring signals from the AGV car and the current sensor, realizing the online fault prediction function of the AGV car, and greatly shortening the maintenance time of the transport vehicle. Reduce maintenance costs and better meet the requirements of AGV's 24-hour efficient operation.

[0017] Use the current sensor to directly connect the battery of the AGV trolley, read the real-time data of the current of the trolley, and then upload the data with the corresponding time stamp and device ID to the local server through the CAN bus, and store these data in the host computer mysql data form historical data records. Finally, the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com